Comprehensive treatment, filtration and recovery device for mud sewage

A comprehensive treatment and recycling device technology, applied in water/sludge/sewage treatment, water/sewage multi-stage treatment, flocculation/sedimentation water/sewage treatment, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in combination with specific embodiments.

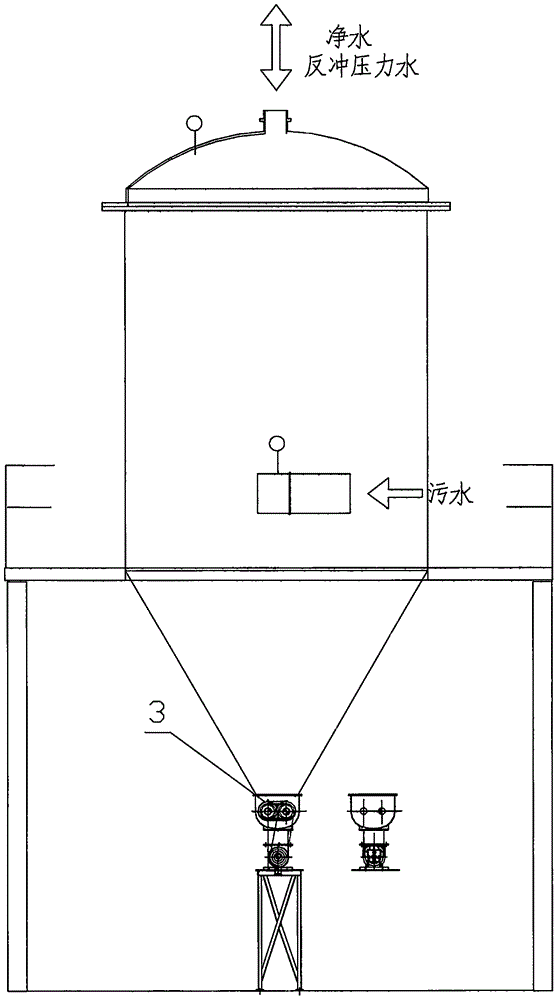

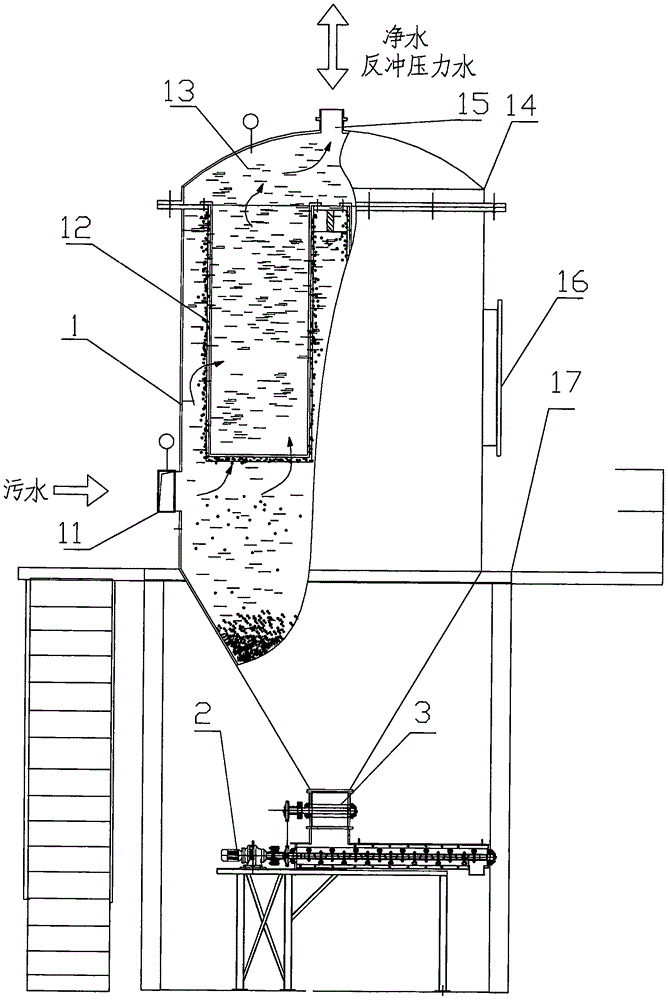

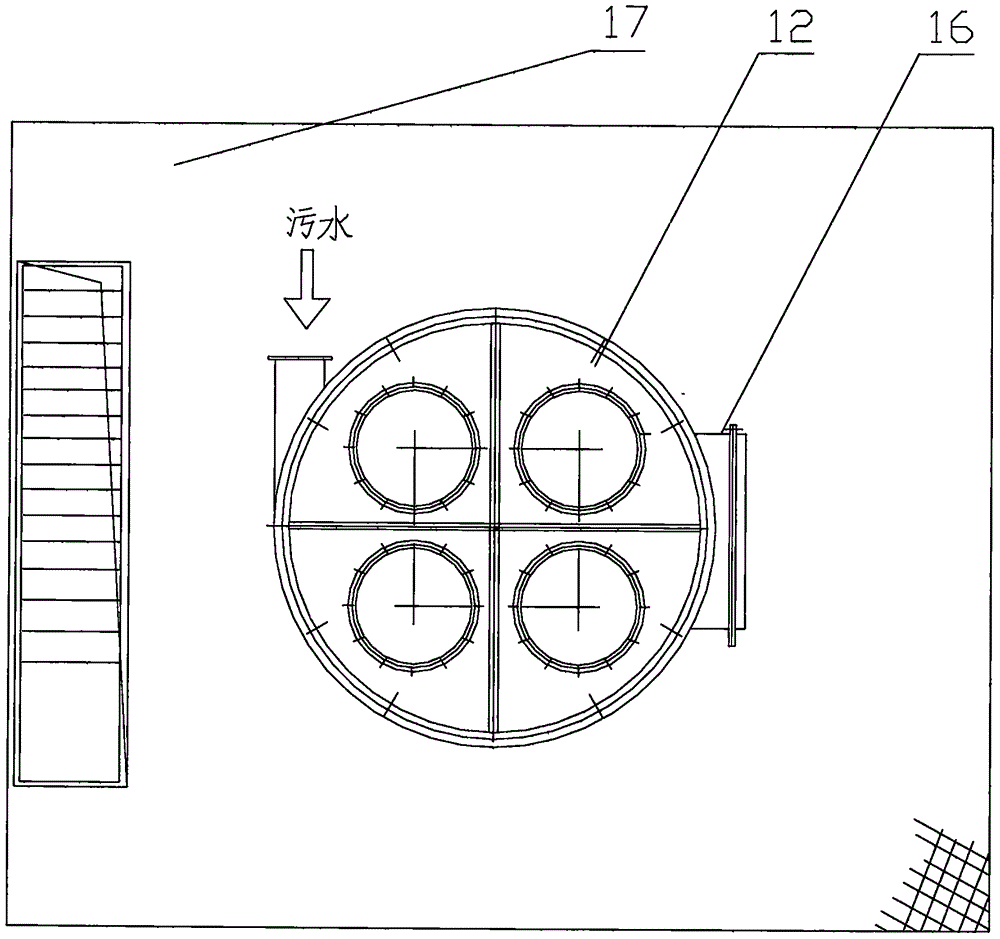

[0020] Such as figure 1 , 2 As shown in and 3, the dust-containing slag-slurry sewage enters the tank body 1 through a slurry pump and an electric valve. 1. Its tangential impulse makes the sewage entering the tank 1 rotate along the inner wall of the tank 1, so that the large particles in the water settle quickly. In addition, after the sludge and sewage are filtered through the filter cartridge 12 of special material, the clean water passes through the back pressure chamber 13 and Drainage pipe 15 gets back to the clean water storage tank and then gets back to the operating system for reuse. The inner and outer mesh cages of the filter cartridge are subjected to a pressure of about 0.3Mpa, and the filter bag shrinks and clings to the inner mesh cage; when a certain thickness of sludge layer accumulates on the outer wall of the filter cartridge, the water inlet pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com