Double-component high-strength hydrogel and preparation method thereof

A hydrogel, two-component technology, applied in the direction of pharmaceutical formulations, medical preparations of non-active ingredients, aerosol delivery, etc., can solve the problems of insufficient strength and slow release effect, and achieve simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] An aqueous solution of polymer 1 (50 repeating units, 1 mL, 50 mg / mL) and an aqueous solution of N-isopropylamine acrylamide-o-hydroxymethylbenzene borate half ester random copolymer (1 mL, 50 mg / mL, pH=7.5) Quickly stir and mix evenly, and stand still for 30 minutes to obtain a hydrogel.

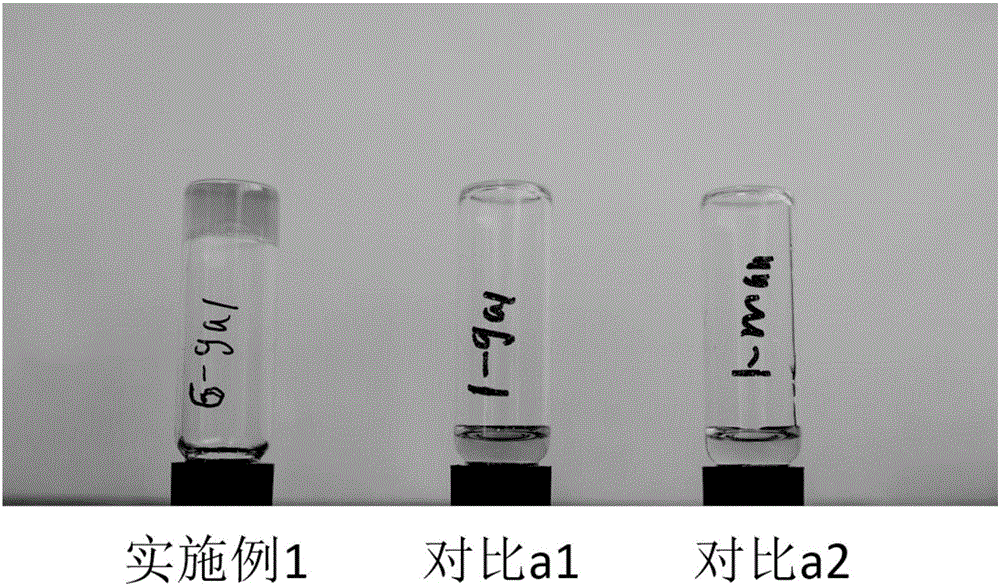

[0036] figure 1 It is an effect comparison chart of the experimental results of Example 1 of the present invention and Comparative Example 1. It can be seen from the figure that under the same component dosage and concentration conditions, Example 1 obtained a hydrogel structure, while the two tests of Comparative Example None of the hydrogel structures were obtained. This is because the dynamic covalent bond formed between the sugar polymer selected in Example 1 and the half-ester of o-hydroxymethylphenylboronic acid is stronger, and the stronger bonding strength can promote the mixture to form a hydrogel structure. In Comparative Example 1, the dynamic covalent bond formed betwee...

Embodiment 2

[0038] An aqueous solution of polymer 2 (100 repeating units, 1 mL, 100 mg / mL) and an aqueous solution of N-isopropylamine acrylamide-o-hydroxymethylbenzene borate half ester random copolymer (1 mL, 100 mg / mL, pH=7.5) Quickly stir and mix evenly, and stand still for 30 minutes to obtain a hydrogel.

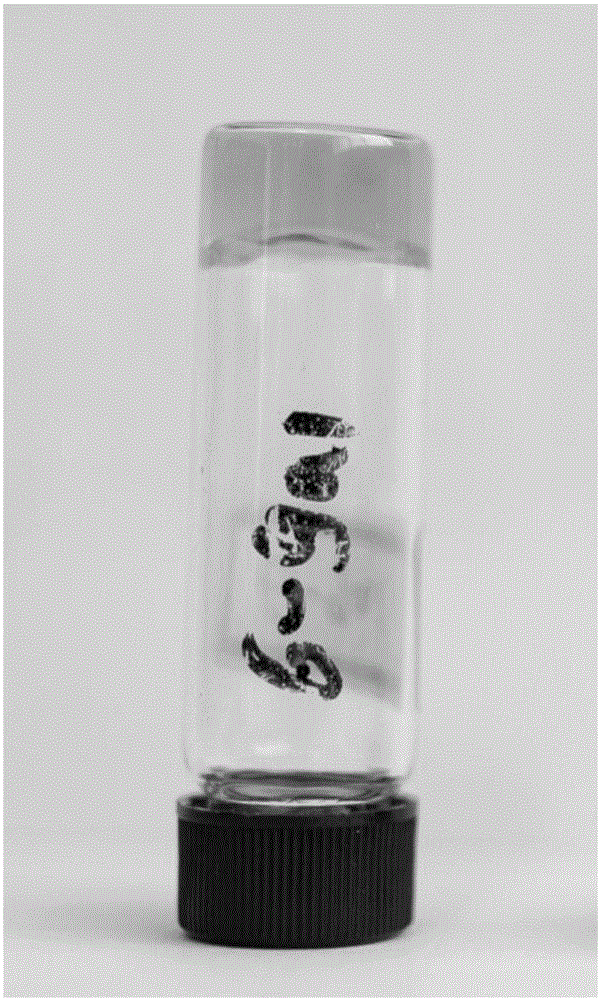

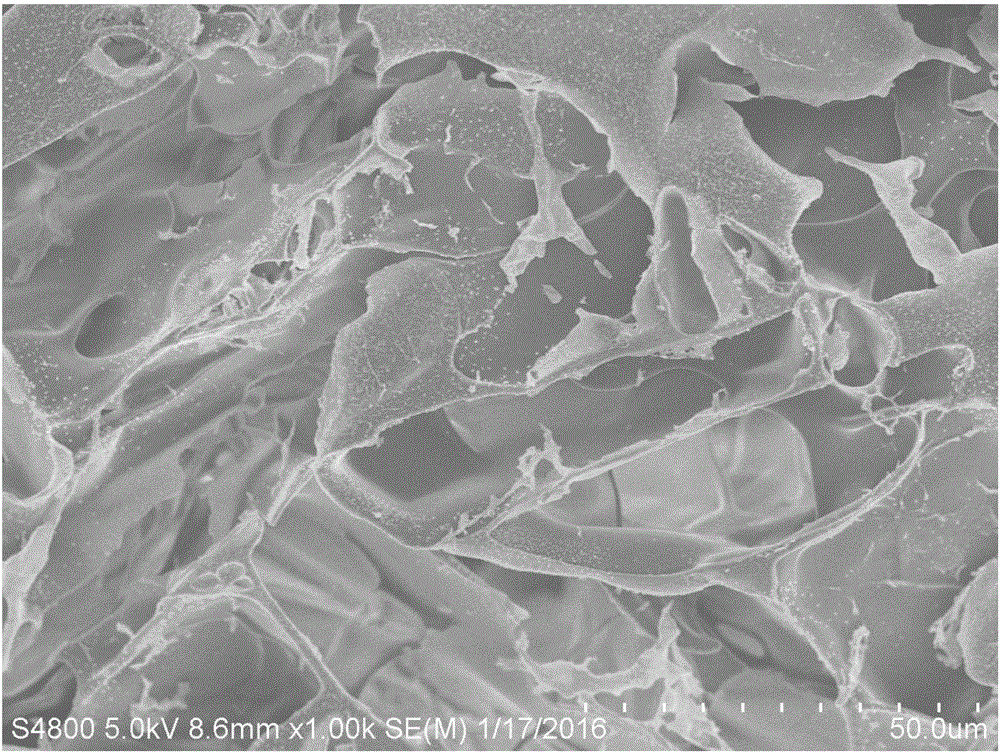

[0039] figure 2 It is the appearance figure of the hydrogel prepared in embodiment 2, image 3 The scanning electron microscope image of the hydrogel prepared in Example 2 of the present invention shows that the gel can form a regular three-dimensional network structure.

[0040] Figure 4 For the storage modulus curves of the hydrogels prepared in Example 2 and Comparative Example 2, it can be seen from the figure that the storage modulus of the hydrogel prepared in Example 2 is much higher than that of the hydrogel prepared in Comparative Example 2. This shows that the hydrogel prepared by the present invention has high strength, which is a new carrier for the development of...

Embodiment 3

[0042] An aqueous solution of polymer 3 (100 repeating units, 1 mL, 200 mg / mL) and an aqueous solution of N-isopropylamine acrylamide-o-hydroxymethylbenzene borate half ester random copolymer (2 mL, 100 mg / mL, pH=7.5) Quickly stir and mix evenly, and stand still for 30 minutes to obtain a hydrogel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com