Method for preparing TiN or CrN film on surface of aluminum alloy through magnetron sputtering method

An aluminum alloy surface, magnetron sputtering technology, applied in sputtering plating, metal material coating process, ion implantation plating and other directions, can solve the problem of lack of preparation process parameters and standards, and achieve uniform and dense film structure, The effect of improving hardness, corrosion resistance, and bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

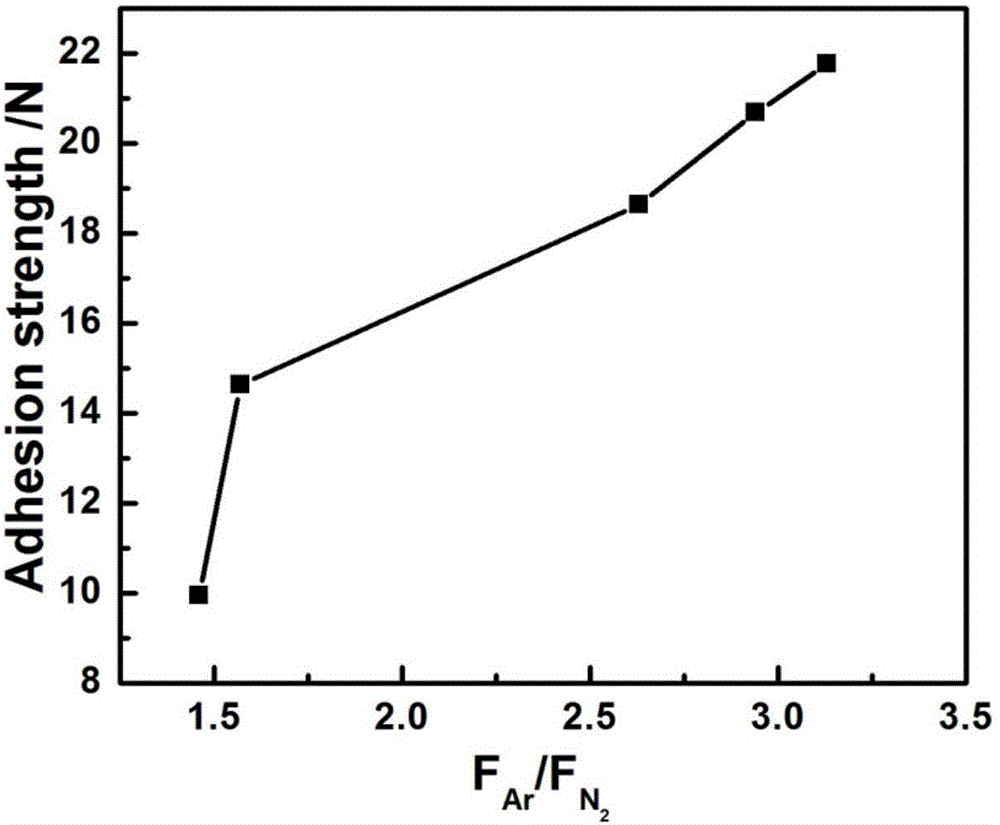

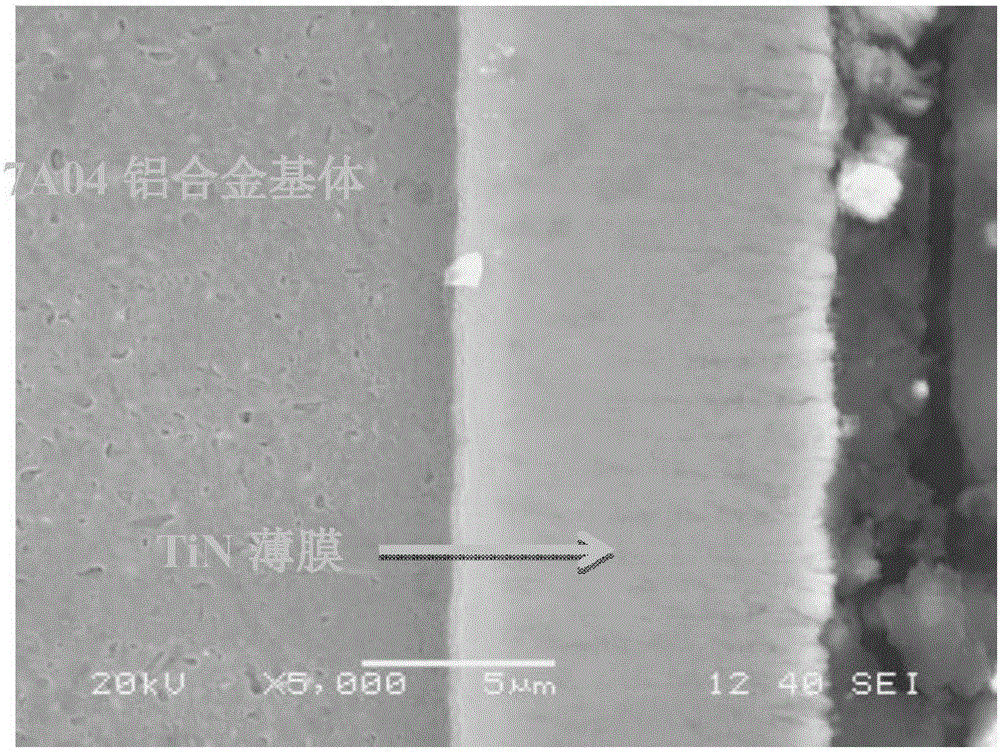

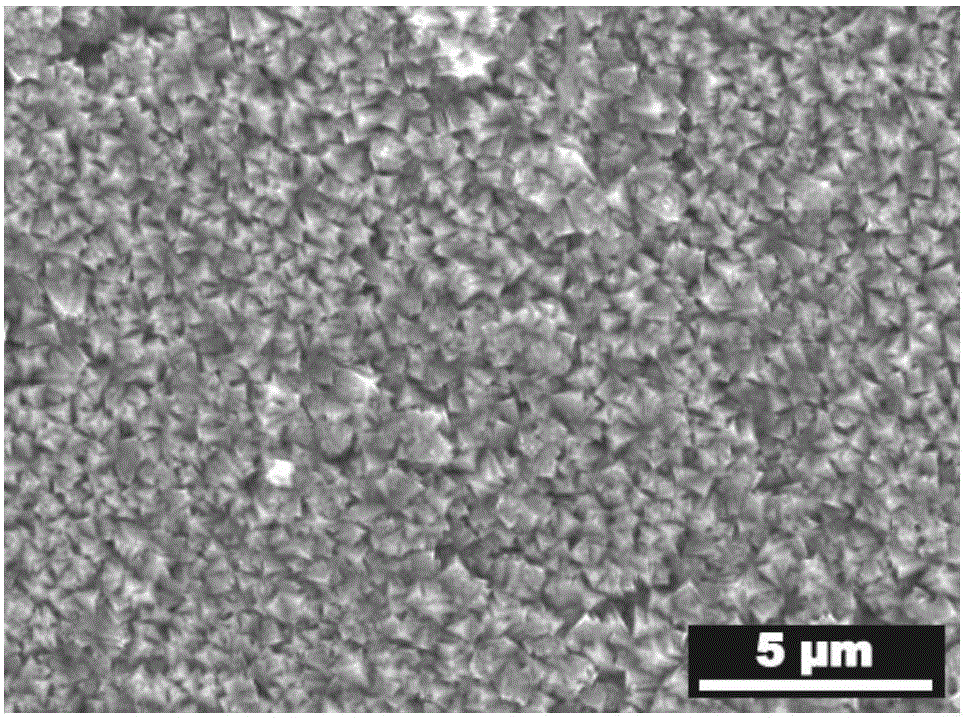

[0053] In this embodiment, a TiN film is prepared on the surface of 7A04 aluminum alloy by magnetron sputtering, and the working gas is argon and nitrogen with a purity of 99.99%.

[0054] Specific steps are as follows:

[0055] 1. Cutting the sample before coating: cutting Φ45mm×2mm aluminum alloy substrate;

[0056] 2. Pretreatment before sputtering: the sample is cleaned before coating, which is divided into two steps: external cleaning and internal cleaning;

[0057] 1) The specific steps for external cleaning are: put the aluminum alloy substrate in absolute ethanol, clean it with ultrasonic waves for 15-20 minutes, then place the aluminum alloy substrate in deionized water, clean it with ultrasonic waves for 20-25 minutes, and finally take out the aluminum alloy Substrate, dry quickly;

[0058] 2) The specific steps of internal cleaning are as follows: hang the aluminum alloy substrate into the chamber of the plasma-enhanced balanced magnetron sputtering equipment. Aft...

Embodiment 2

[0073] In this embodiment, a CrN film was prepared on the surface of 7A04 aluminum alloy by magnetron sputtering, and argon and nitrogen with a purity of 99.99% were selected as working gases;

[0074] Specific steps are as follows:

[0075] 1. Cut the sample before coating: cut the Φ50mm×3mm aluminum alloy substrate according to the required specifications;

[0076] 2. Pretreatment before sputtering: the sample is cleaned before coating, which is divided into two steps: external cleaning and internal cleaning;

[0077] 1) The specific steps for external cleaning are: put the aluminum alloy substrate in absolute ethanol, clean it with ultrasonic waves for 15-20 minutes, then place the aluminum alloy substrate in deionized water, clean it with ultrasonic waves for 20-25 minutes, and finally take out the aluminum alloy Substrate, dry quickly;

[0078] 2) The specific steps of internal cleaning are as follows: hang the aluminum alloy substrate into the chamber of the plasma-enh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com