Formaldehyde-free easy-ironing and finishing method for pure cotton woven fabric

A woven fabric, pure cotton technology, applied in the treatment of textile materials, fabric rubbing/softening treatment, fabric surface trimming and other directions, can solve the problems of decreased fabric softness, itchiness when wearing, unfavorable human health, etc. Visibly boned, soft to the touch, tactile and plump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

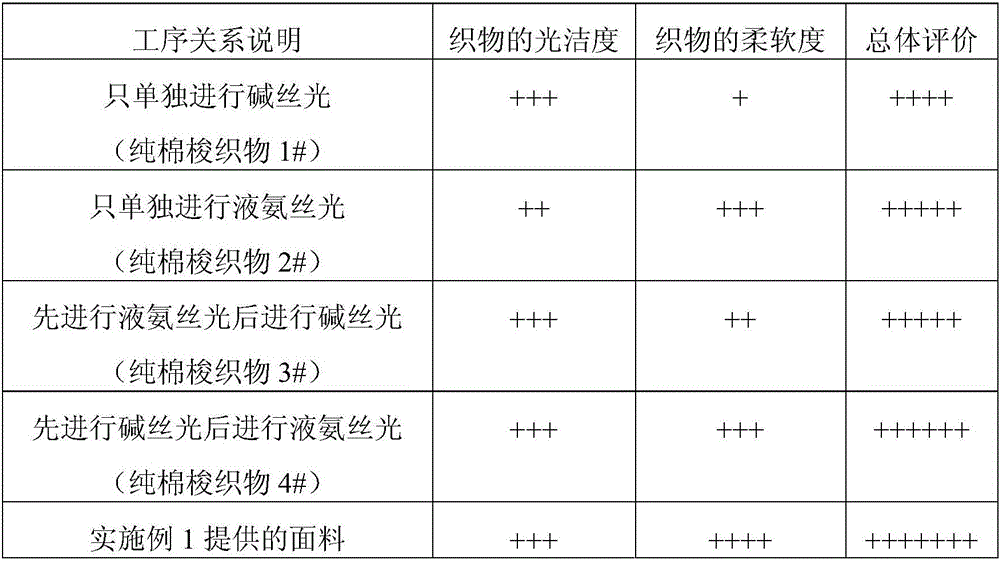

Image

Examples

Embodiment 1

[0031] This embodiment provides a formaldehyde-free easy ironing finishing method for pure cotton woven fabrics. The single yarn count of pure cotton woven fabrics is 50S. The method comprises the following steps:

[0032] (1) Perform pretreatment (including singeing and desizing) on pure cotton woven fabrics according to the traditional pretreatment process;

[0033] (2) immerse the pure cotton woven fabric in the alkali solution of 24 degrees Baume to carry out the mercerizing alkali mercerizing treatment, and the treatment time is 1min;

[0034] (3) A liquid ammonia mercerizing machine jointly produced by Japan's Kyoto Machinery Co., Ltd. and Japan's Maekawa Works was used to carry out liquid ammonia mercerizing treatment on pure cotton woven fabrics, with a speed of 60m / min and a processing time of 20s;

[0035] (4) Pad the fabric with the working solution containing ternary copolymerization softener T620 and crosslinking agent T821, and bake it at 150°C for 3 minutes af...

Embodiment 2

[0041] This embodiment provides a formaldehyde-free easy ironing finishing method for pure cotton woven fabrics. The single yarn count of pure cotton woven fabrics is 60S. The method comprises the following steps:

[0042] (1) Perform pretreatment (including singeing and desizing) on pure cotton woven fabrics according to the traditional pretreatment process;

[0043] (2) Immerse pure cotton woven fabric in lye solution of 20 degrees Baume to carry out mercerizing alkali mercerizing treatment, the treatment time is 45s, and control the cloth surface pH value of the fabric to be 6-7.5 after alkali mercerizing is finished;

[0044] (3) A liquid ammonia mercerizing machine jointly produced by Japan's Kyoto Machinery Co., Ltd. and Japan's Maekawa Works was used to carry out liquid ammonia mercerizing treatment on pure cotton woven fabrics, with a speed of 65m / min and a processing time of 9s;

[0045] (4) Pad the fabric with the working solution containing ternary copolymerizatio...

Embodiment 3

[0051]This embodiment provides a formaldehyde-free easy ironing finishing method for pure cotton woven fabrics. The single yarn count of pure cotton woven fabrics is 80 / 2. The method comprises the following steps:

[0052] (1) Perform pretreatment (including singeing and desizing) on pure cotton woven fabrics according to the traditional pretreatment process;

[0053] (2) immerse the pure cotton woven fabric in the alkali solution of 24 degrees Baume to carry out the mercerizing alkali mercerizing treatment, and the treatment time is 60s;

[0054] (3) A liquid ammonia mercerizing machine jointly produced by Japan's Kyoto Machinery Co., Ltd. and Japan's Maekawa Works was used to carry out liquid ammonia mercerizing treatment on pure cotton woven fabrics, with a speed of 45m / min and a processing time of 20s;

[0055] (4) Pad the fabric with the working solution containing ternary copolymerization softener T620 and crosslinking agent T821, and bake it at 150°C for 3 minutes aft...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com