Printing and dyeing method for anti-ant antibacterial anti-infrared camouflage fabric and camouflage fabric

An anti-infrared and camouflage technology, applied in the field of printing and dyeing, can solve the problems of poor anti-infrared effect, performance conflict, and single function, and achieve the effects of improving durability, solving performance conflicts and reductions, and improving functional durability and wearability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

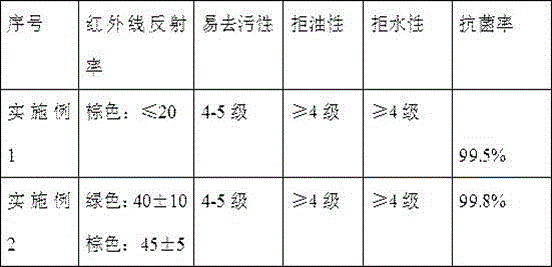

Embodiment 1

[0033] The printing and dyeing method of anti-mosquito antibacterial anti-infrared camouflage fabric comprises the following steps:

[0034] (1) Cold stacking: dip the camouflage fabric into the cold stacking working fluid, control the vehicle speed at 60±1 m / min, roll the cloth into a large roll, wrap it tightly with plastic film after rolling, and stack it at room temperature for 12 hours to obtain Cold-stack fabrics; in the process of padding and cold-stacking working fluid, the excess rate is 75%; the formula of cold-stacking working fluid is: sodium hydroxide 2g / L, scouring agent HB-101 3g / L, hydrogen peroxide 4g / L, Stabilizer water glass 5g / L and chelating agent TH3055 2g / L;

[0035] (2) Scouring and bleaching: The cold-stacked fabric is soaked and bleached with the working solution of scouring and bleaching in the way of double dipping and rolling, and then steamed at 100°C for 60 minutes to obtain the scouring and bleaching fabric; during the process of padding, scouri...

Embodiment 2

[0048] The printing and dyeing method of anti-mosquito antibacterial anti-infrared camouflage fabric comprises the following steps:

[0049] (1) Cold stacking: dip the camouflage fabric into the cold stacking working fluid, control the speed of 60 m / min, roll the cloth into a large roll, wrap it tightly with plastic film after rolling, and stack it at room temperature for 8 hours to obtain cold stacking Fabric; in the process of padding cold batch working fluid, the excess rate is 80%; the formula of cold batch working fluid is: sodium hydroxide 3g / L, scouring agent HB-101 2g / L, hydrogen peroxide 5g / L, stabilizer Water glass 8g / L and chelating agent TH3055 5g / L;

[0050] (2) Scouring and bleaching: The cold-stacked fabrics are soaked in the scouring and bleaching working solution by two dipping and two rolling methods, and then steamed at 110°C for 70 minutes to obtain the scouring and bleaching fabrics; m / min, liquid carrying rate 90%; the formula of scouring and bleaching w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com