Vertical structure AlGaInP-based light-emitting diode and manufacturing method thereof

A light-emitting diode and vertical structure technology, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of high production cost, numerous production steps, and low yield rate, and achieve the effect of simple manufacturing method and high product quality rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

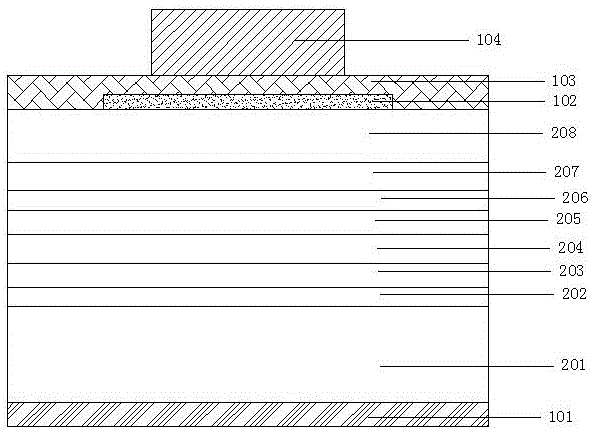

[0024] like figure 1 Shown:

[0025] 1. Manufacturing process:

[0026] 1. Making epitaxial wafers: using MOCVD equipment to sequentially grow N-GaAs buffer layer 202, AlAs / AlGaAs reflective layer 203, N-AlGaInP lower confinement layer 204, MQW multiple quantum well active Layer 205, P-AlGaInP upper confinement layer 206, P-GaInP buffer layer 207, P-GaP current spreading layer 208 doped with magnesium.

[0027] Among them, the P-GaP current spreading layer 208 preferably has a thickness of 4000 nm, and the doping elements are all magnesium (Mg), and the doping concentration is 2×10 19 cm -3 , to ensure a certain current expansion capability.

[0028] 2. Use No. 215 and No. 511 cleaning solutions to clean the P-GaP current spreading layer 208, and deposit SiO with a thickness of 100-350 nm on it by PECVD 2 , SiNx, TiO or TiO 2 Any one of them can be spin-coated with a positive photoresist, exposed and developed to produce a specific pattern. After plasma bonding, BOE was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com