Transistor vertical-cavity surface-emitting laser

A technology of vertical cavity surface emission and lasers, which is applied in the direction of semiconductor lasers, lasers, laser components, etc., can solve the problems of losing enhanced modulation bandwidth and restricting device performance, so as to reduce adverse effects, reduce production costs, and improve lateral distribution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

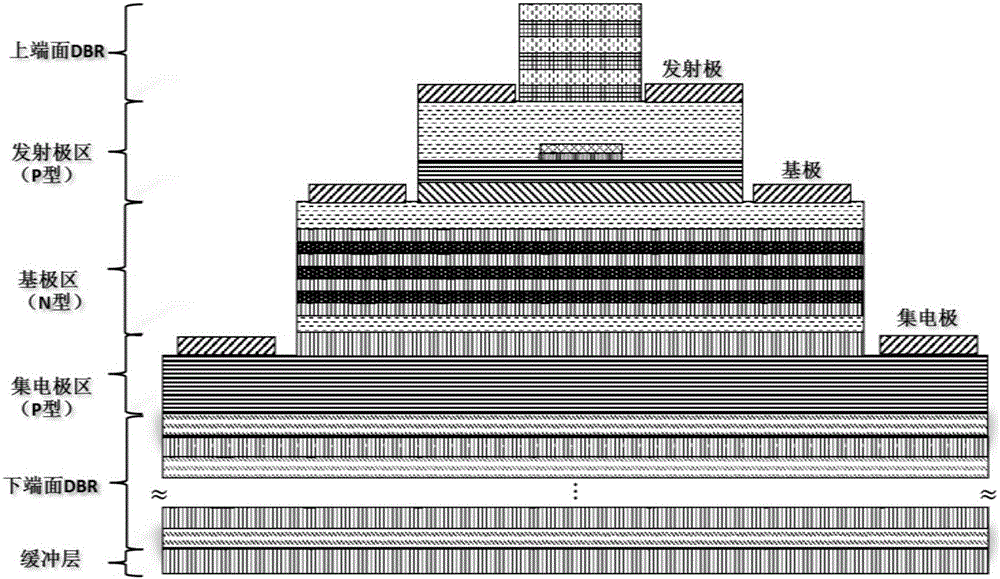

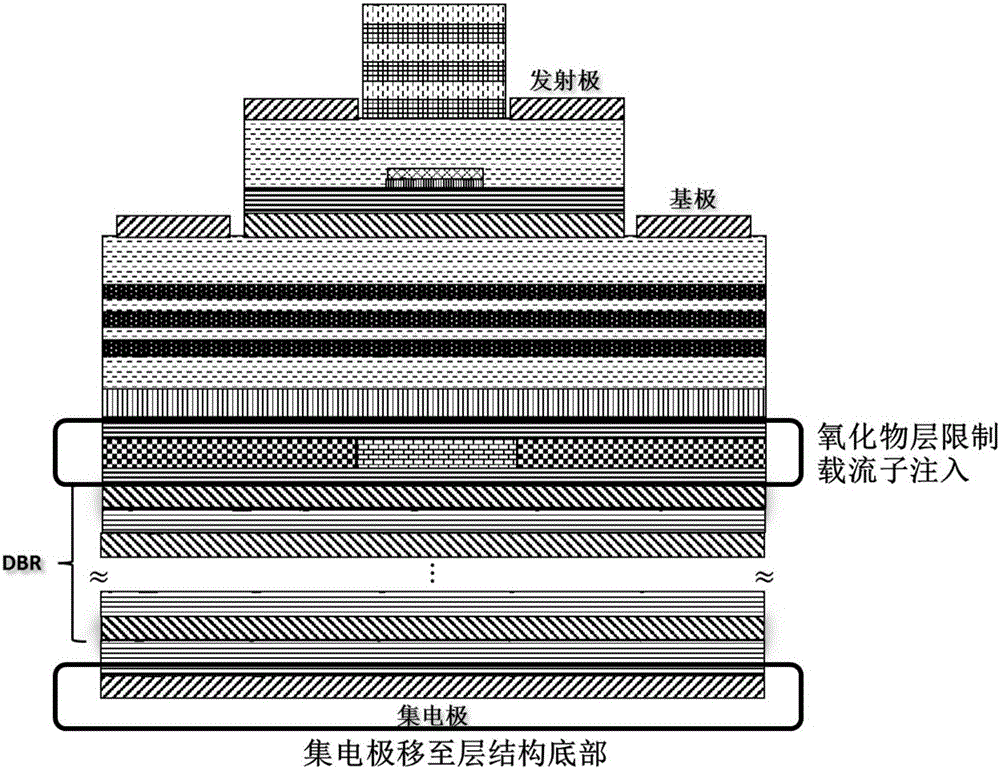

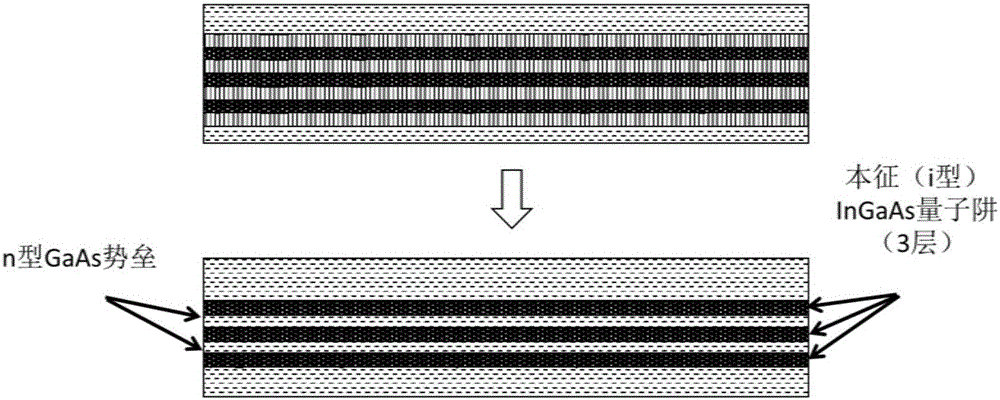

[0029] There is an important defect in the existing T-VCSEL: as the input current increases, the working state of the device changes rapidly from amplification to saturation, thus losing the function of enhancing the modulation bandwidth. The essential reason is that due to the limited injection of carriers, stimulated radiation mainly occurs in the active region near the center of the device, but the overall movement path of carriers includes not only the vertical direction along the center of the device, but also Due to the horizontal direction brought by the position of the corresponding electrode, and the path length of the latter is much longer than that of the former, this is especially evident in the collector region. The thickness of the layer structure of the entire device is only a few microns, and the distance between the collector and the cen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com