Multistage vertical partition fire prevention system for tunnel

A technology for tunnels and fire prevention devices, which can be used in fire rescue, medical science, dental prosthetics, etc. It can solve the problems of unsatisfactory separation between smoke and combustion-supporting air, poor timing of closing, and affecting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

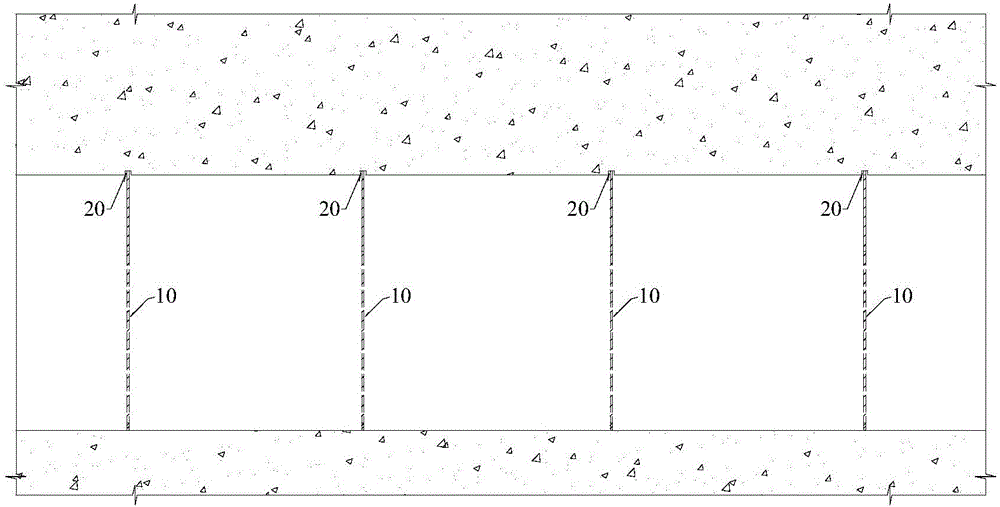

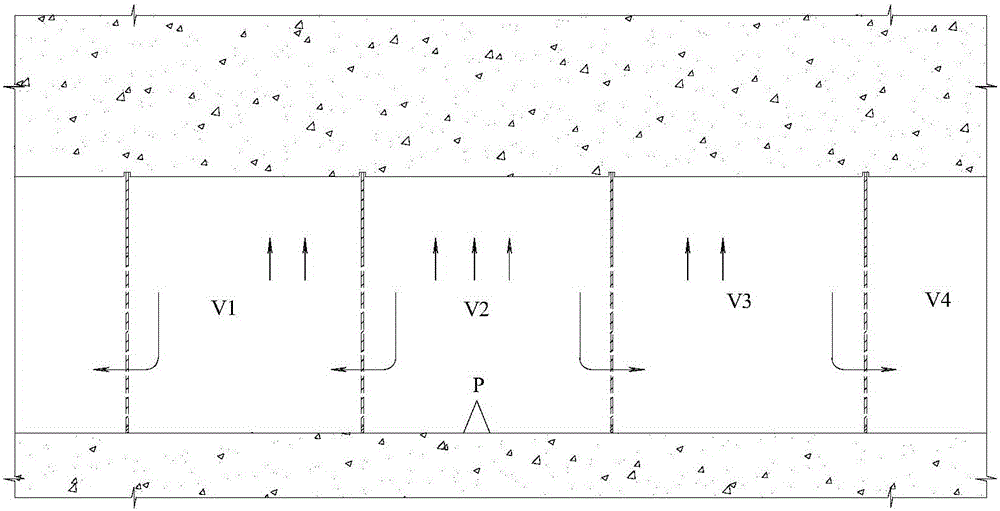

[0016] refer to figure 1 , a tunnel multi-stage vertical partition fire protection system of the present invention includes a flexible tunnel fire protection device with a retractable fire protection curtain 10 . The flexible tunnel fire protection device is arranged at continuous intervals along the extension direction of the tunnel in the tunnel cavity. Form a plurality of partition spaces, and form a labyrinth seal between the multiple partition spaces and the tunnel cavities on both sides, effectively partition the fire point from the surrounding tunnel space, avoid the rapid and large-scale diffusion of smoke generated by the fire, and block a large number of Oxygen-enriched air continues to enter the fire point, providing a safe passage for the evacuation of personnel in the tunnel and the entry of fire-fighting equipment.

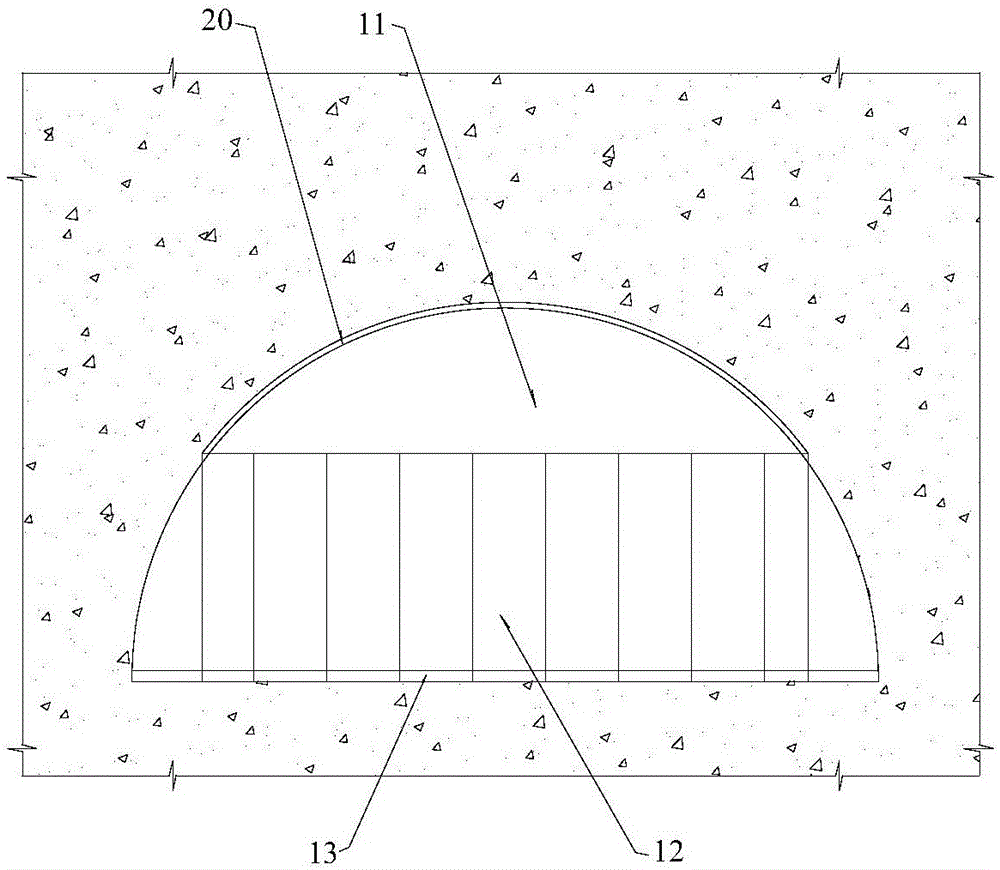

[0017] refer to fig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com