A technology for pretreatment of complex and refractory gold concentrates by industrial microwave

A technology for refractory gold and industrial microwave, which is applied in the field of industrial microwave pretreatment of complex and refractory gold concentrate and gold smelting to achieve the effects of promoting decomposition and oxidation, reducing activation energy and shortening the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

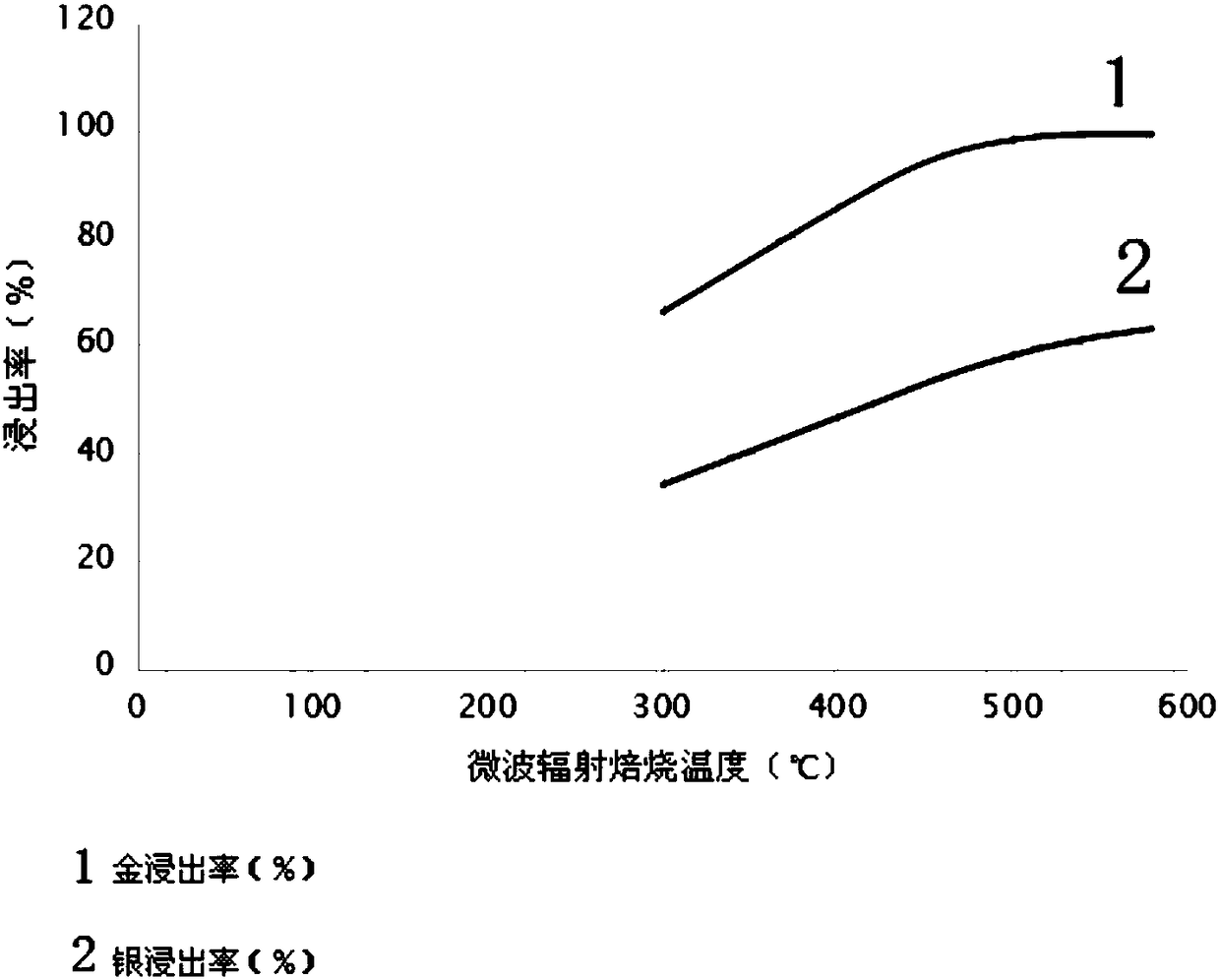

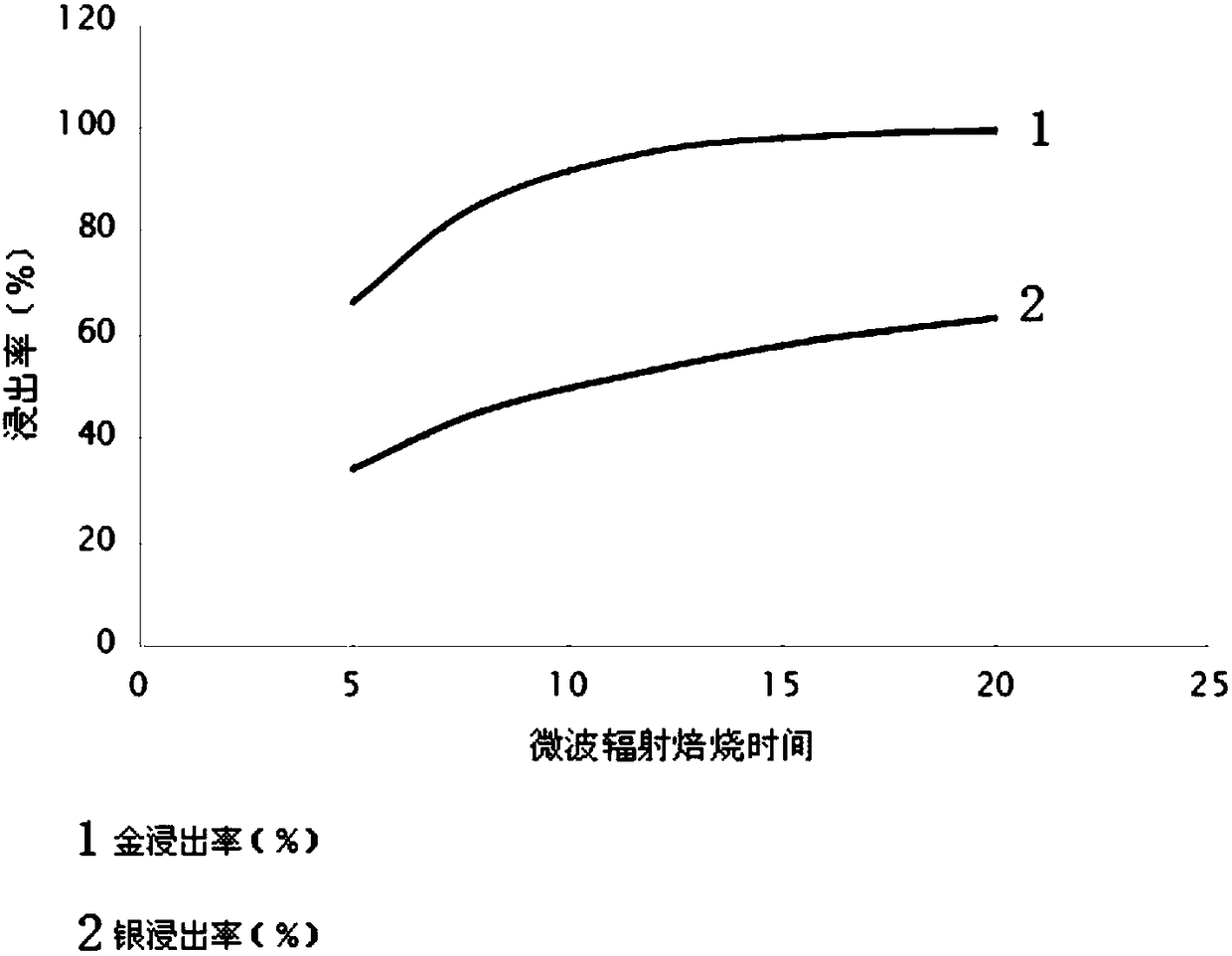

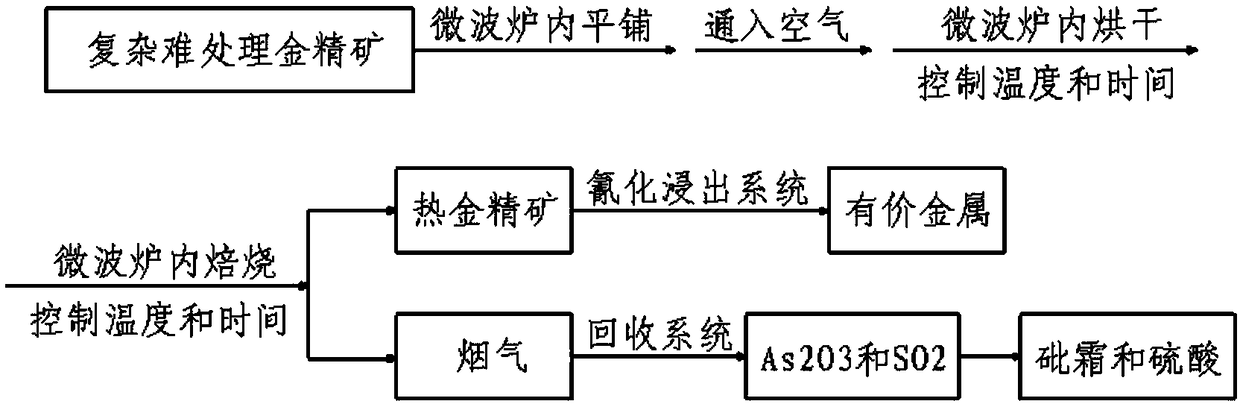

[0018] Embodiment 1: A kind of process technology of complex refractory gold concentrate with industrial microwave pretreatment, described technical process is carried out according to the following steps: the first step puts complex refractory gold concentrate into continuous horizontal belt type industrial microwave oven shop The thickness of the ore layer is 25-100mm. Turn on the fan of the microwave oven and let in the air. In the second step, start the microwave heating device to dry and roast the complex and refractory gold concentrate obtained in the first step. The microwave frequency in the drying section is controlled. The microwave source is 915MHz, the power level of the single tube of the microwave source is 3kW, 5kW, the temperature of the drying section is controlled at 120°C ~ 140°C, and the drying time is 5 ~ 10 minutes; the microwave frequency of the roasting section is controlled at 915MHz, and the power of the single tube of the microwave source is The stage...

Embodiment 2

[0020] Embodiment 2: A kind of process technology of complex refractory gold concentrate with industrial microwave pretreatment, described technical process is carried out according to the following steps: the first step puts complex refractory gold concentrate into continuous horizontal belt-type industrial microwave oven shop The thickness of the ore layer is 25-100mm. Turn on the fan of the microwave oven and let in the air. In the second step, start the microwave heating device to dry and roast the complex and refractory gold concentrate obtained in the first step. The microwave frequency in the drying section is controlled. The microwave source is 915MHz, the single-tube power level of the microwave source is 5kW, 10kW, the temperature of the drying section is controlled at 140°C-160°C, and the drying time is 10-15 minutes; the microwave frequency of the roasting section is controlled at 915MHz, and the power level of the single-tube microwave source is The grades are 20kW...

Embodiment 3

[0022] Embodiment 3: A kind of process technology of complex refractory gold concentrate with industrial microwave pretreatment, described technical process is carried out according to the following steps: the first step puts complex refractory gold concentrate into continuous horizontal belt type industrial microwave oven shop The thickness of the ore layer is 25-100mm. Turn on the fan of the microwave oven and let in the air. In the second step, start the microwave heating device to dry and roast the complex and refractory gold concentrate obtained in the first step. The microwave frequency in the drying section is controlled. The microwave source is 2450MHz, the single-tube power level of the microwave source is 1kW, 5kW, the temperature of the drying section is controlled at 160°C-200°C, and the drying time is 15-20 minutes; the microwave frequency of the roasting section is controlled at 2450MHz, and the power level of the single-tube microwave source is The stage is 50kW,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com