Gold recovery technology for processing arsenious S-C gangue coated gold concentrate by microwave fluidized roasting

A technology of boiling roasting and wrapping gold, applied in the direction of improving process efficiency, can solve the problems of high equipment requirements, harsh production conditions, and high maintenance costs, and achieve the effects of reducing energy consumption, promoting monomer dissociation, and improving recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

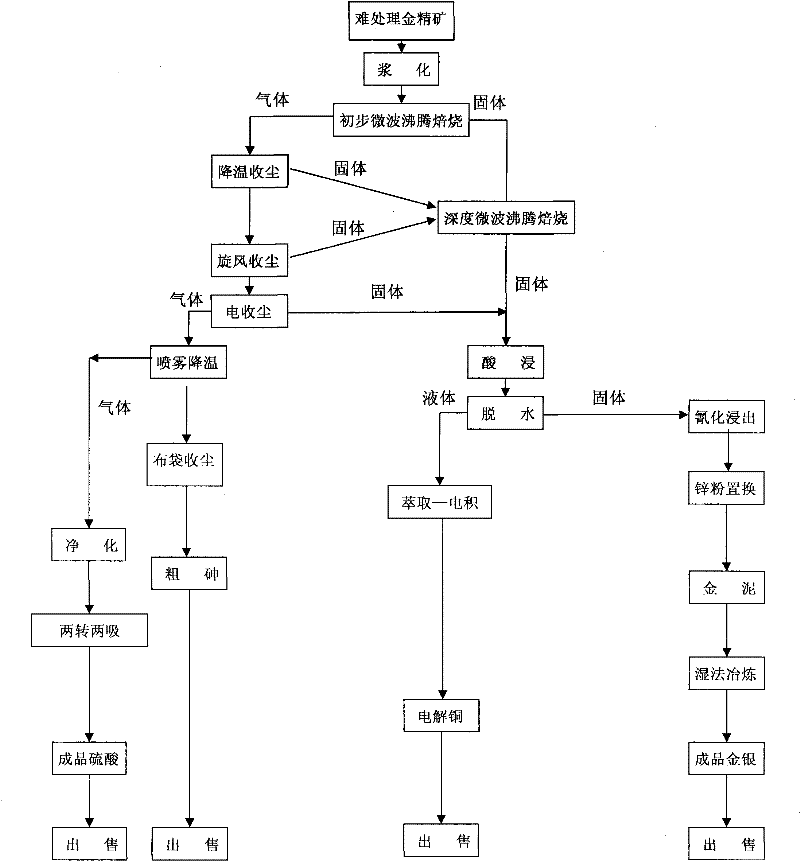

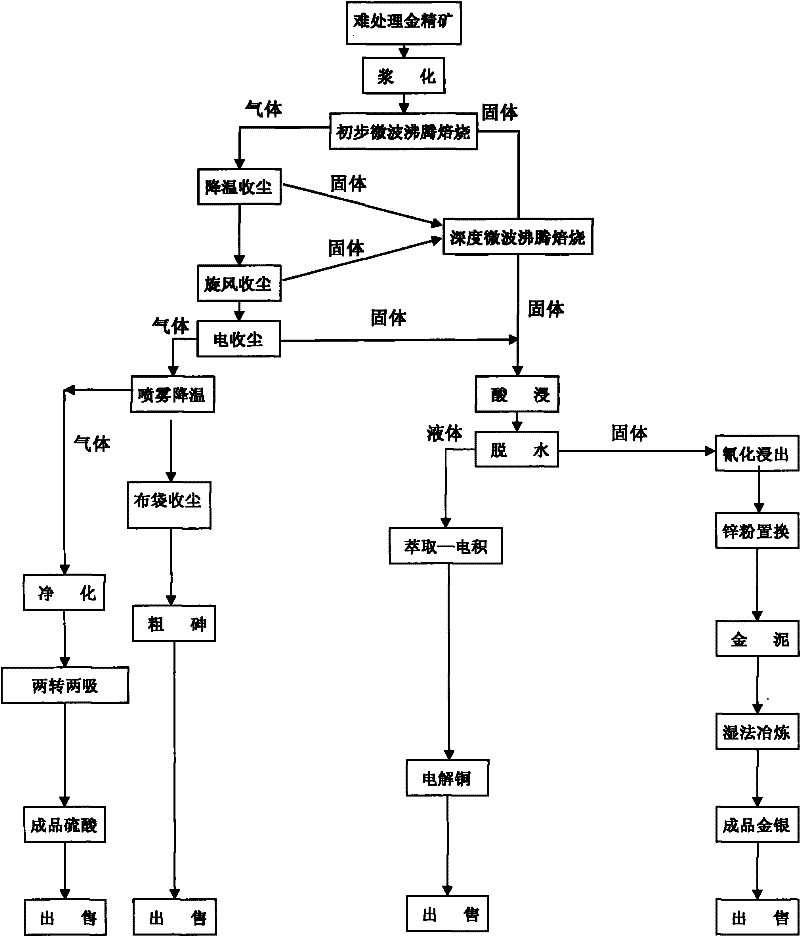

Method used

Image

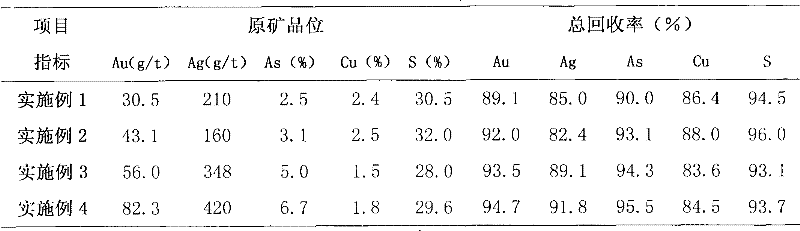

Examples

Embodiment 1

[0026] (1) Preparation of ore pulp: the arsenic, sulfur, carbon, and gangue-containing gold concentrate with a particle size of less than 200 meshes accounting for 60% is rationally blended to make a slurry with a liquid-solid weight ratio of 1:2.5. In the preparation of the ore pulp Add sodium carbonate according to 20kg / t gold concentrate, fully stir for 4 hours;

[0027] (2) Preliminary microwave boiling roasting: pump the slurry obtained in step (1) into the preliminary microwave boiling furnace, blow in an appropriate amount of air for preliminary microwave boiling roasting (microwave frequency is 2.45GHz, power is 600W) for 1.5 hours, and adjust the furnace temperature by adding water at 610°C, most of the iron in the gold concentrate is oxidized to Fe 3 o 4 , arsenic is represented by As, As 2 S 3 、As 3 o 4 , sulfur to SO 2 , S 2 state into the smoke;

[0028] (3) Deep microwave boiling roasting: send the calcined sand produced in step (2) together with the dust...

Embodiment 2

[0033] (1) Preparation of ore pulp: Properly blend the arsenic, sulfur, carbon, and gangue-containing gold concentrates with a particle size of less than 200 meshes that account for 80% to make a slurry with a liquid-solid weight ratio of 1:3.5. Add sodium hydroxide according to 15kg / t gold concentrate, and fully stir for 3 hours;

[0034] (2) Preliminary microwave boiling roasting: the ore slurry obtained in step (1) is pumped into a preliminary microwave boiling furnace, and an appropriate amount of air is blown in to carry out preliminary microwave boiling roasting (microwave frequency is 1GHz, power is 200W) for 2 hours, and the furnace temperature is regulated by adding water. 625°C;

[0035] (3) Deep microwave boiling roasting: the calcined sand produced in step (2) and the dust collected in the flue gas are sent into the deep microwave boiling furnace together, and a large amount of air is blown into to carry out deep microwave boiling roasting (the microwave frequency ...

Embodiment 3

[0038] (1) Preparation of ore pulp: Properly blend the arsenic, sulfur, carbon, and gangue-containing gold concentrates with a particle size of less than 300 meshes and account for 70% to make a slurry with a liquid-solid weight ratio of 1:2.8. Add sodium nitrate according to 10kg / t gold concentrate, and fully stir for 2 hours;

[0039] (2) Preliminary microwave boiling roasting: the ore slurry obtained in step (1) is pumped into a preliminary microwave boiling furnace, and an appropriate amount of air is blown in to carry out preliminary microwave boiling roasting (microwave frequency is 20GHz, power is 400W) for 1 hour, and the furnace temperature is regulated by adding water. 600°C;

[0040] (3) Deep microwave boiling roasting: the calcined sand produced in step (2) and the dust collected in the flue gas are sent into the deep microwave boiling furnace together, and a large amount of air is blown in for deep microwave boiling roasting (the microwave frequency is 10GHz, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com