Anti-aging anti-static fireproof heat insulation wall and installation method thereof

A fire-proof, heat-preservation and anti-static technology, which is applied in the direction of heat preservation, fire protection, walls, etc., can solve the problems of compressing the size of indoor space, bulky wall structure, and occupying indoor space, so as to achieve good anti-static effect, improve mechanical properties, and increase flexibility sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

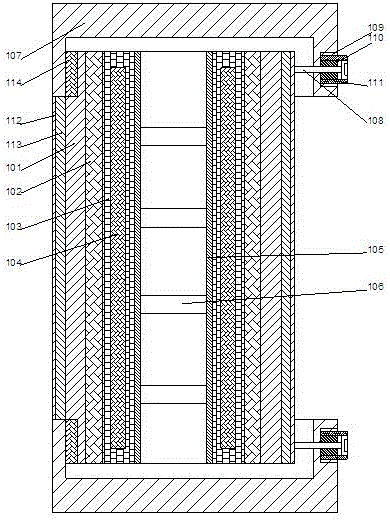

[0013] Such as figure 1 As shown, an anti-aging, anti-static, fire-proof and thermal insulation wall includes two outer layers 101 made of laminated boards and thermal insulation rock wool layers 102 respectively arranged inside the two outer layers 101. Fireproof paint layers 112 are respectively arranged on the outer walls of the outer layer boards 101, and the outer layer boards 101 are bonded to the heat insulating rock wool layer 102 through a fireproof adhesive, and the heat insulating rock wool layer 102 Reinforcement skeletons 103 are arranged on the inner side respectively, and the two described reinforcement skeletons 103 are cage structures formed by a number of parallel longitudinally arranged reinforcements surrounded by transverse reinforcements on the outside, and a cavity is arranged in the middle of the reinforcement skeletons 103. The cavity is filled with a thermal insulation layer 104, fixed plates 105 are respectively arranged on the opposite end faces of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com