Low-stroboflash AC LED circuit

A LED light string and LED drive technology, applied in electric light sources, electrical components, electroluminescent light sources, etc., can solve problems such as adverse stimulation of the visual nerve center, eye fatigue and even headaches, and achieve reduced switching power and stroboscopic flicker , Improve the effect of power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

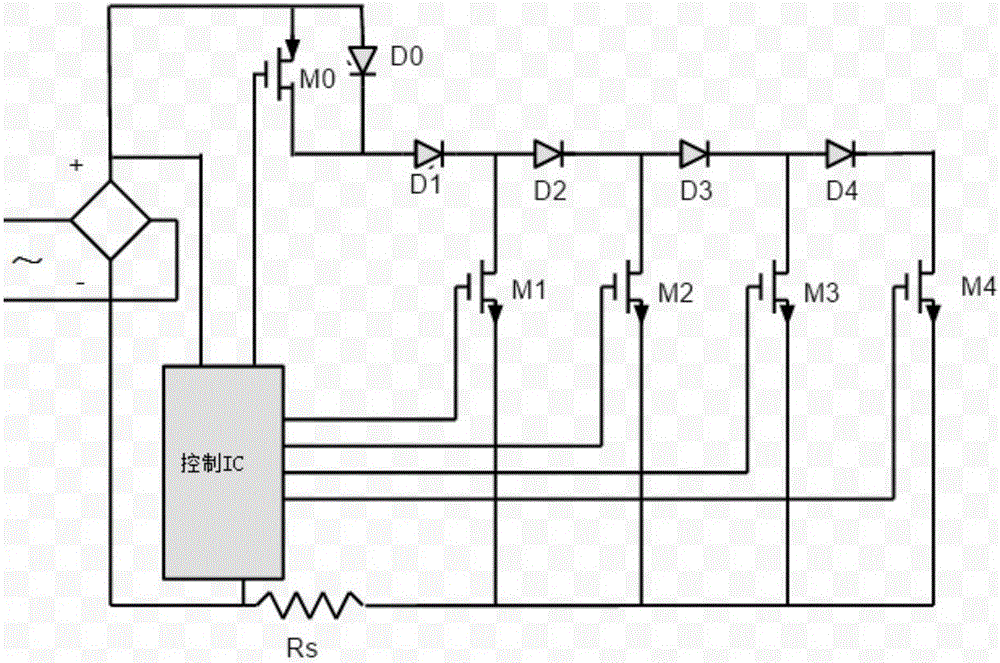

[0026] Embodiment 1: see figure 1 , a low-frequency flashing AC LED drive circuit, including: drive IC, LED light string D0, LED light string D1, LED light string D2, LED light string D3, LED light string D4, PMOS tube M0, PMOS tube M1, PMOS tube M2, PMOS tube M3, PMOS tube M4, current limiting resistor Rs;

[0027] The control IC is used to control the gate voltage of PMOS transistor M0, PMOS transistor M1, PMOS transistor M2, PMOS transistor M3, and PMOS transistor M4;

[0028] The positive pole of the LED light string D0 is connected to the source level of the PMOS tube M0, and the negative pole of the LED light string D0 is connected to the drain level of the PMOS tube M0;

[0029] LED light string D0, LED light string D1, LED light string D2, LED light string D3, LED light string D4 are connected in series, the conduction voltage of LED light string D0 is less than half of the conduction voltage of LED light string D4 ;The maximum power of LED light string D1, LED ligh...

Embodiment 2

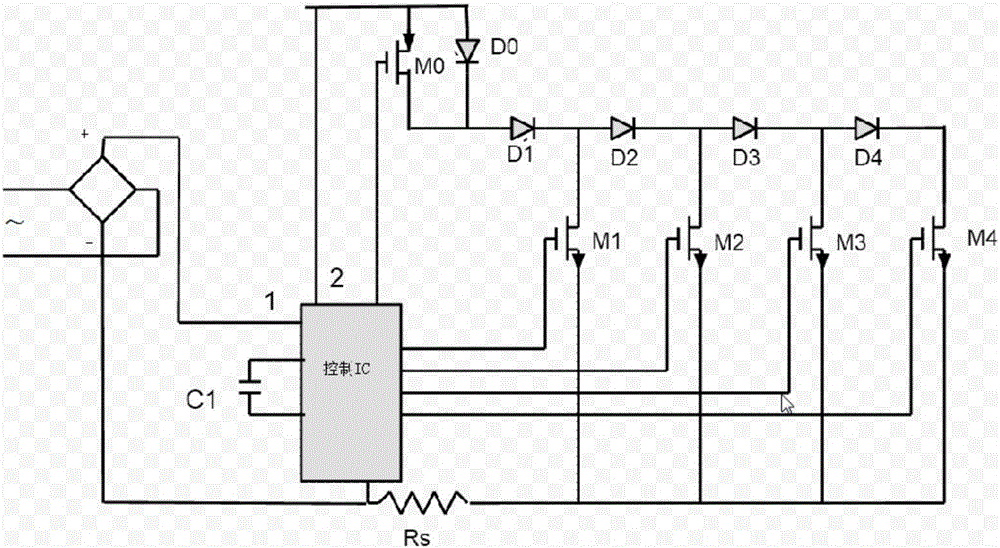

[0041] Embodiment 2. On the basis of the low-flicker AC LED drive circuit in Embodiment 1, a valley-filling circuit is added to the DC power supply end. The valley-filling circuit is used to improve the power factor of the DC power supply, thereby reducing stroboscopic flicker.

Embodiment 3

[0042] Example 3, see figure 2 , on the basis of a low-frequency flashing AC LED drive circuit in Embodiment 1, the energy storage capacitor control pin of the drive IC is added with an energy storage capacitor C1. When the drive IC judges that the input DC power is zero, the LED light string D0, Light string D1, LED light string D2, LED light string D3, LED light string D4 power supply, eliminate the DC power supply when the LED light string D0, LED light string D1, LED light string D2, LED light string D3, LED light string D4 Strobe caused by extinguishing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com