A high-flux electrochemical filtration sewage treatment device

A sewage treatment device, electrochemical technology, applied in the direction of water/sewage treatment, water/sewage treatment equipment, water/sludge/sewage treatment, etc. In order to avoid mechanical damage, reduce electrode distance, and operate flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

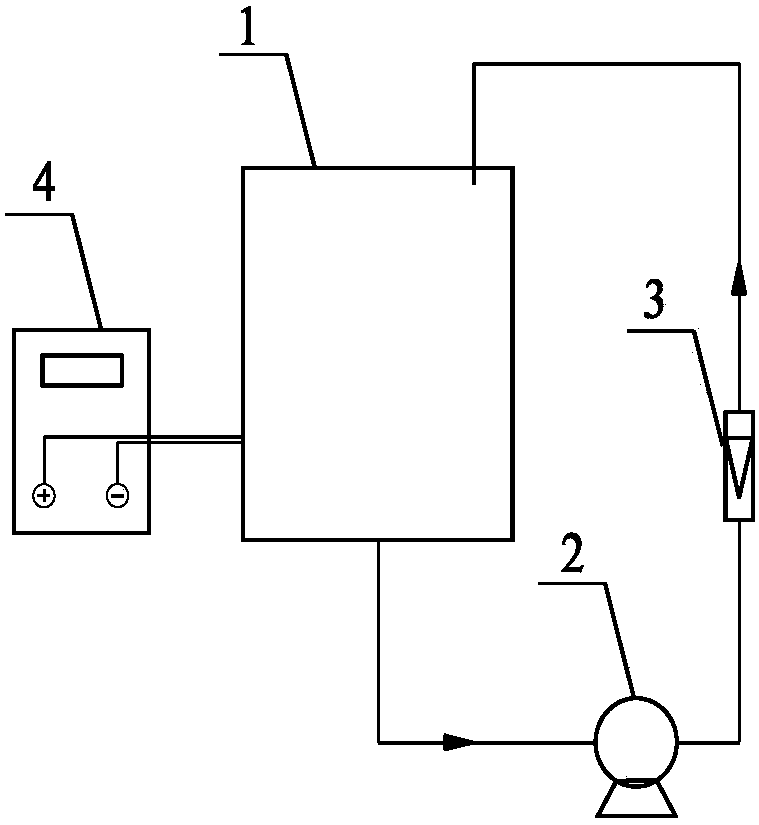

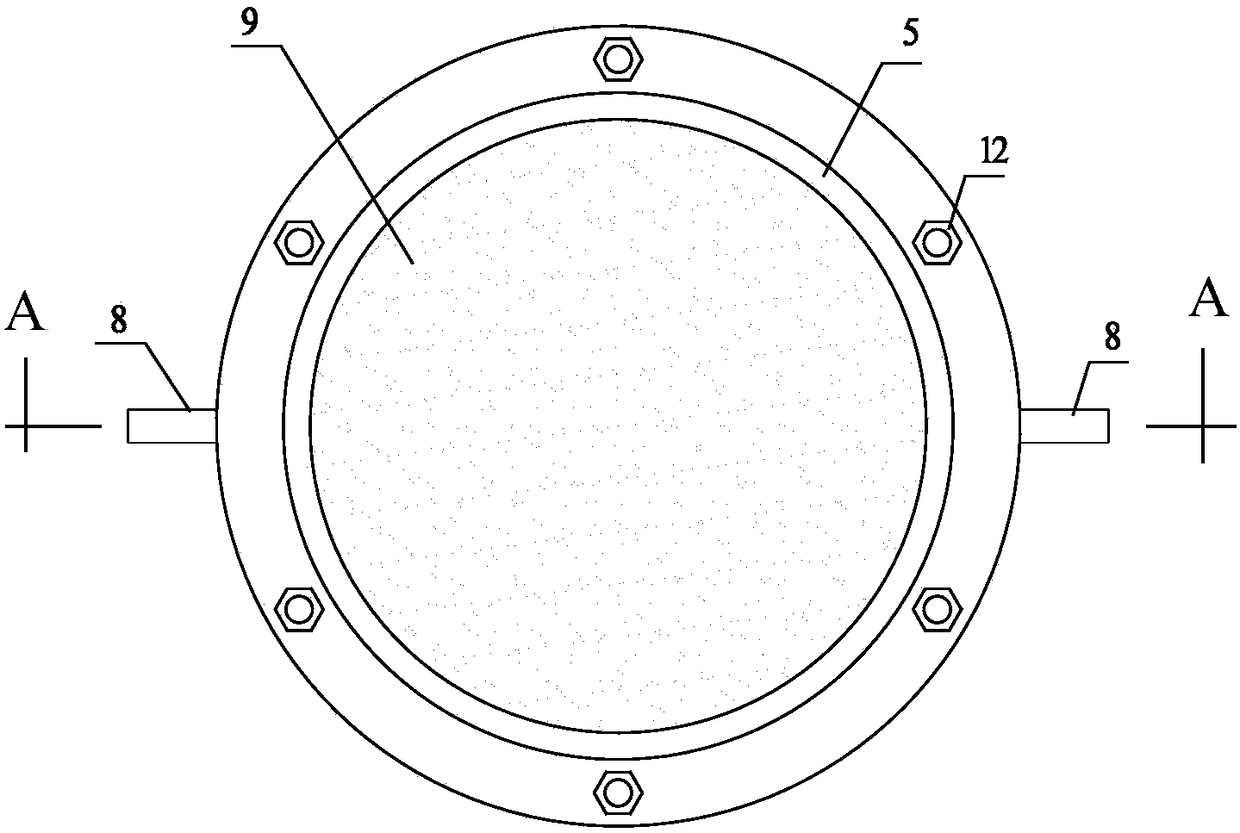

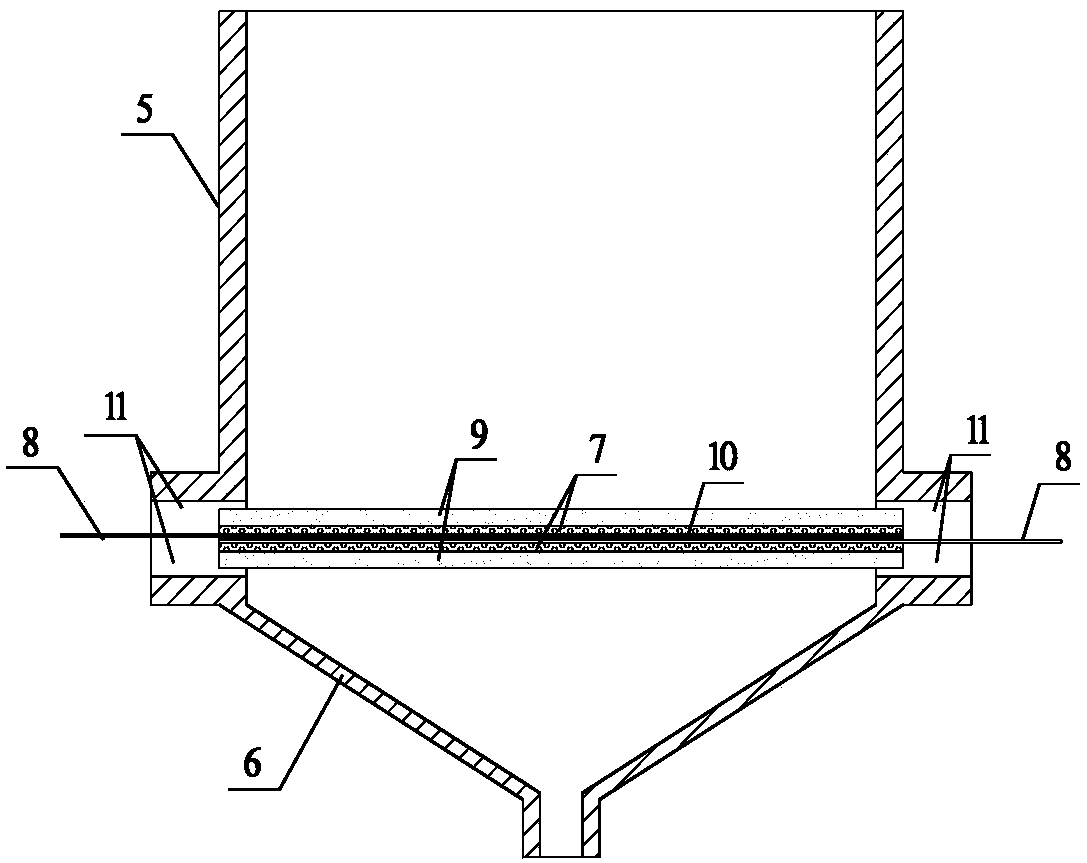

[0025] In order to achieve the above object, the present invention is achieved in that the whole system includes an electrochemical filter reactor, a circulation pump, a flow meter and a DC power supply. Its characteristics are: the electrochemical filter reactor assembly is composed of a support, a cylinder, carbon nanotube electrodes and connecting parts, a porous insulating rigid diaphragm, a porous insulating flexible diaphragm, and a sealing part. The reactor cylinder and support are made of polytetrafluoroethylene (PTFE), or polyethylene (PE), or ABS, or PVC-U and other oxidation-resistant insulating plastics. The reactor cylinder and the support are connected and sealed by nuts and bolts + silicone gaskets. The porous insulating flexible membrane separates the two layers of carbon nanotube membrane electrodes; the porous insulating flexible membrane is absorbent cotton cloth, or polyvinylidene fluoride (PVDF) membrane, or cellulose acetate filter membrane. The connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com