Stone flour concrete composite admixture and preparation method thereof

A composite admixture and concrete technology, applied in the field of building materials, can solve problems such as flushing into rivers, polluting the environment, wasting resources, etc., and achieve the effects of reducing the amount of water used, protecting the environment, and reducing waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

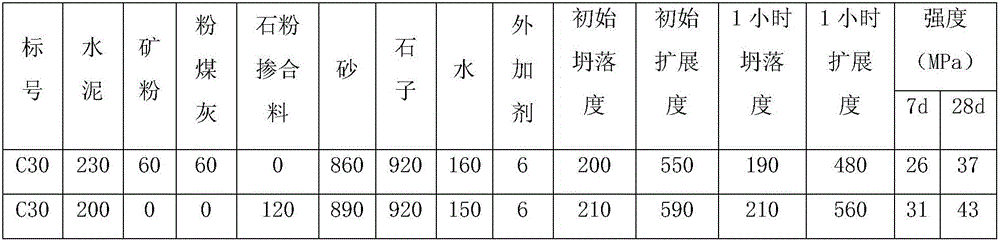

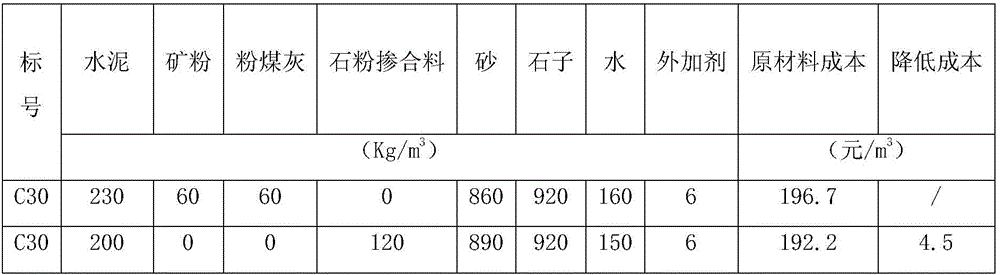

Image

Examples

Embodiment 1

[0026] Embodiment 1. A kind of stone powder concrete composite admixture, comprises the raw material of following weight percent:

[0027] Stone powder 20%, smelting waste residue 20%, burnt clay 10%, pozzolanic materials 15%, cement clinker 25%, dolomite 5%, gypsum 5%.

[0028] The smelting waste slag is phosphorus slag, nickel slag, steel slag, slag, iron slag, lead-zinc slag and copper slag mixed in equal proportions.

[0029] The pozzolanic material is a natural pozzolanic material.

[0030] The preparation method steps are as follows:

[0031] (1) Take the above-mentioned raw materials according to weight percentage.

[0032] (2) Grind the above-mentioned materials except stone powder separately, and control the particle size to 10-32mm; add 0.05%-0.3% activator and 0.3%-0.5% functional regulator for each material during the separate grinding process.

[0033] (3) Then all the materials are uniformly mixed by a combination mixer to obtain a composite admixture, and the...

Embodiment 2

[0034] Embodiment 2. A kind of stone powder concrete composite admixture, comprises the raw material of following weight percent:

[0035] Stone powder 62%, smelting waste slag 10%, burnt clay 5%, pozzolanic materials 5%, cement clinker 10%, dolomite 3%, gypsum 5%.

[0036] The smelting waste slag is phosphorus slag, nickel slag, steel slag and slag mixed according to the mass ratio of 1:2:3.

[0037] The pozzolanic material is coal gangue.

[0038] The preparation method steps are as follows:

[0039] (1) Take the above-mentioned raw materials according to weight percentage.

[0040] (2) All materials are mixed and ground with a three-chamber tube mill, the fineness of 45 μm is controlled between 10%-13%, and 0.05%-0.3% activator + 0.3%-0.5% functional regulator is added during the grinding process. After milling, a composite admixture is obtained.

Embodiment 3

[0041] Embodiment 3. A kind of stone powder concrete composite admixture, comprises the raw material of following percentage by weight:

[0042] 45% stone powder, 20% smelting waste residue, 10% burnt clay, 5% pozzolanic material, 10% cement clinker, 5% dolomite, 5% gypsum, the sum of the weight percentages of the above components is 100%.

[0043] The smelting waste slag is iron ore slag.

[0044] The pozzolanic material is a mixture of natural pozzolanic material and andesite in a mass ratio of 2:1.

[0045] The preparation method steps are as follows:

[0046] (1) Take the above-mentioned raw materials according to weight percentage.

[0047] (2) Grind the above-mentioned materials except stone powder separately, and control the particle size to 10-32mm; add 0.05%-0.3% activator and 0.3%-0.5% functional regulator for each material during the separate grinding process.

[0048] (3) Then all the materials are uniformly mixed by a combination mixer to obtain a composite adm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com