Preparation method of nilotinib intermediate-3-(4-methyl-1H-imidazol-1-yl)-5-(trifluoromethyl)aniline

A technology of trifluoromethylaniline and trifluoromethyl, which is applied in the field of preparation of nilotinib intermediate 3--5-aniline, can solve the problems of low reaction yield, large environmental pollution, and unsuitability for industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

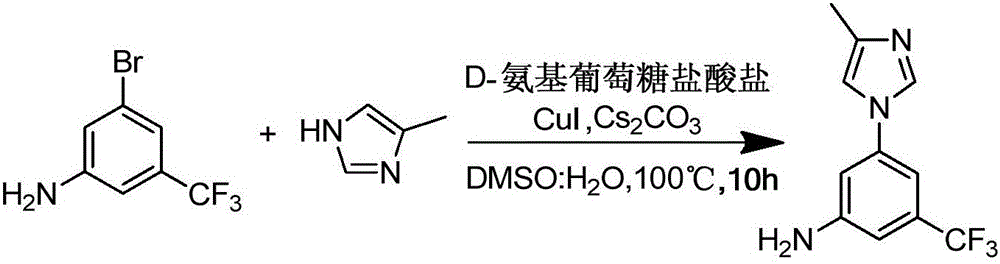

Embodiment 1

[0020] In the there-necked flask, add 24g (0.1mol) 3-bromo-5-trifluoromethylaniline, 8.2g (0.1mol) 4-methylimidazole, 65.2g (0.2mol) Cs 2 CO 3 , 1.9g (0.01mol) CuI, 2.2g (0.01mol) D-glucosamine hydrochloride, then add 50mL DMSO and 50mL water, stir to dissolve, control the reaction temperature at 100°C, and continue the reaction for 10 hours. Add 100mL ethyl acetate after completion of the reaction, get the supernatant after centrifugation, concentrate and dry to obtain 3-(4-methyl-1H-imidazol-1-yl)-5-(trifluoromethyl)aniline, the HPLC purity is 98.53%, the yield is 95.25%.

Embodiment 2

[0022] In the reaction vessel, add 24g (0.1mol) 3-bromo-5-trifluoromethylaniline, 8.2g (0.1mol) 4-methylimidazole, 58.7g (0.18mol) Cs 2 CO 3 , 0.95g (0.005mol) CuI, 1.1g (0.005mol) D-glucosamine hydrochloride, then add 60mL DMSO and 80mL water, stir to dissolve it, control the reaction temperature to 90°C, and continue to react for 12 hours. After completion, 120 mL of ethyl acetate was added, and the supernatant was taken after centrifugation, concentrated and dried to obtain 3-(4-methyl-1H-imidazol-1-yl)-5-(trifluoromethyl)aniline. The HPLC purity was 98.66%, and the yield was 96.18%.

Embodiment 3

[0024] In the reaction vessel, add 24g (0.1mol) 3-bromo-5-trifluoromethylaniline, 8.2g (0.1mol) 4-methylimidazole, 71.7g (0.22mol) Cs 2 CO 3 , 3.8g (0.02mol) CuI, 4.4g (0.02mol) D-glucosamine hydrochloride, then add 80mL DMSO and 60mL water, stir to make it dissolve, control the reaction temperature to be 110°C, and continue to react for 8 hours. After completion, add 160 mL of ethyl acetate, take the supernatant after centrifugation, concentrate and dry to obtain 3-(4-methyl-1H-imidazol-1-yl)-5-(trifluoromethyl)aniline. The HPLC purity was 98.09%, and the yield was 95.77%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com