Folding-white free transparent polypropylene material and preparation method thereof

A technology of transparent polypropylene and polypropylene materials, applied in the field of chemical engineering, can solve the problems of easy cracking, low price, poor high temperature resistance, etc., and achieve the effects of good whitening resistance, good fatigue resistance, and good transparency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

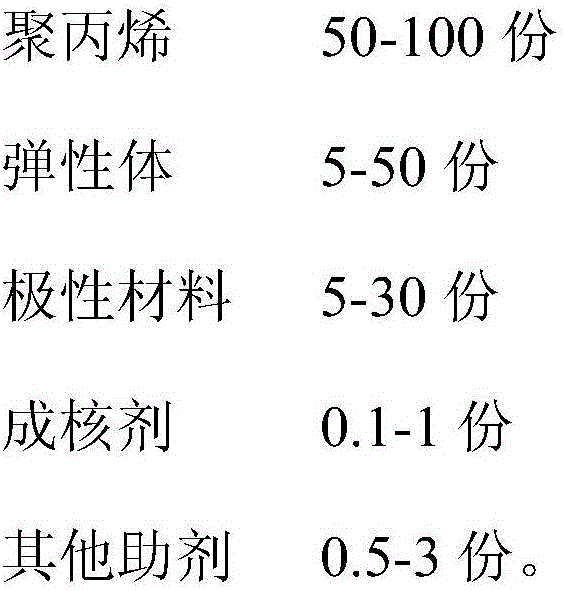

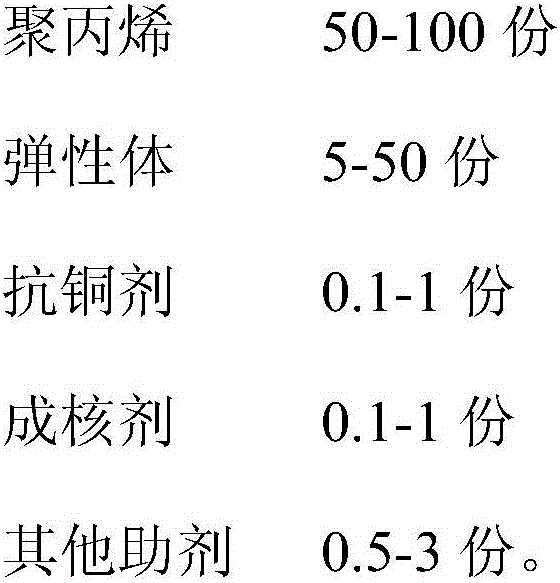

Method used

Image

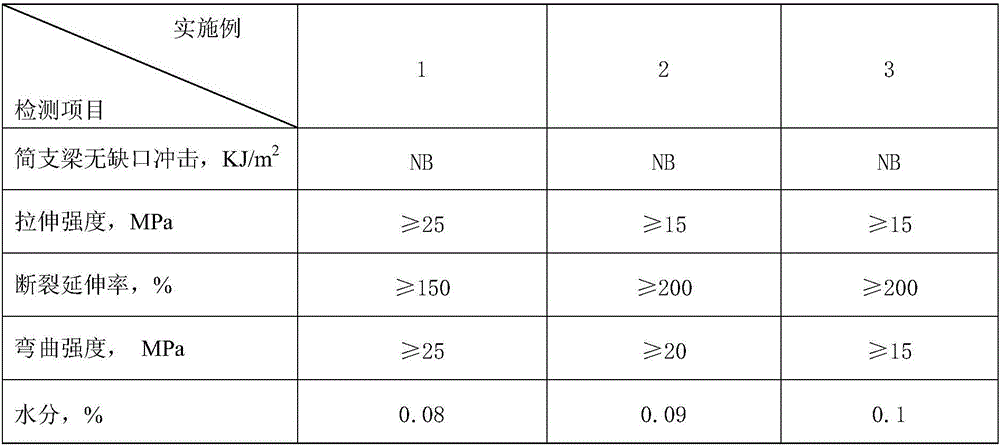

Examples

Embodiment 1

[0027] A polar non-folding white transparent polypropylene material, the raw materials include the following parts by weight: polypropylene T30S: 80 parts, melt index 2-4g / 10min, polybutene elastomer: 10 parts, maleic anhydride grafted PP : 10 parts, nucleating agent Meride 3988: 0.3 parts, 1010 and 168 according to the mass ratio of 1:1 compound antioxidant, lubricant EBS 1.1 parts, of which 1010, 168 each 0.3 parts, EBS 0.5 parts;

[0028] A preparation method of polar non-folding white transparent polypropylene material, comprising the steps of:

[0029] 1) Mix, add polypropylene, polybutylene elastomer, maleic anhydride grafted polypropylene, nucleating agent Meride 3988, 1010 and 168 according to the mass ratio of 1:1 compound antioxidant, lubricant EBS In the high mixer, first mix at low speed for 30 seconds, then mix at high speed for 1 minute;

[0030] 2) Extrusion and granulation. After setting the temperature in each zone of the twin-screw extruder, add the mixed ma...

Embodiment 2

[0033] A polar non-folding white transparent polypropylene material, the raw materials include the following parts by weight: polypropylene T30S: 70 parts, melt index 2-4g / 10min, polybutene elastomer: 20 parts, maleic anhydride grafted PP : 10 parts, nucleating agent Meride 3988: 0.3 parts, 1010 and 168 according to 1:1 mass ratio compound antioxidant, lubricant EBS total 1.1 parts, of which 1010, 168 each 0.3 parts, EBS 0.5 parts;

[0034] Method is with embodiment 1.

Embodiment 3

[0036] The maleic anhydride grafted polypropylene in the polar non-folding white transparent polypropylene material raw material in embodiment 2 is replaced with polar resin EVA, and other raw materials are the same as embodiment 2;

[0037] A preparation method of polar non-folding white transparent polypropylene material, comprising the steps of:

[0038] 1) Mix, add polypropylene, polybutylene elastomer, maleic anhydride grafted polypropylene, nucleating agent Meride 3988, 1010 and 168 according to the mass ratio of 1:1 compound antioxidant, lubricant EBS In the high mixer, first mix at low speed for 60 seconds, then mix at high speed for 3 minutes;

[0039] 2) Extrusion and granulation. After setting the temperature in each zone of the twin-screw extruder, add the mixed materials in step 1) to the twin-screw extruder for mixing, and carry out traction cooling and air-drying for granulation;

[0040] The parameters of the twin-screw extruder are as follows: feeding section...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt finger | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com