Preparation method of silicone rubber-based flexible and deformable electric-conducting and heating composite film

A silicone rubber and flexible-based technology, which is applied in the field of preparation of flexible polymer-based conductive heating films, can solve the problems of unstable conductive network and easy damage of conductive network, and achieve the effect of maintaining heating performance, improving conductivity and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

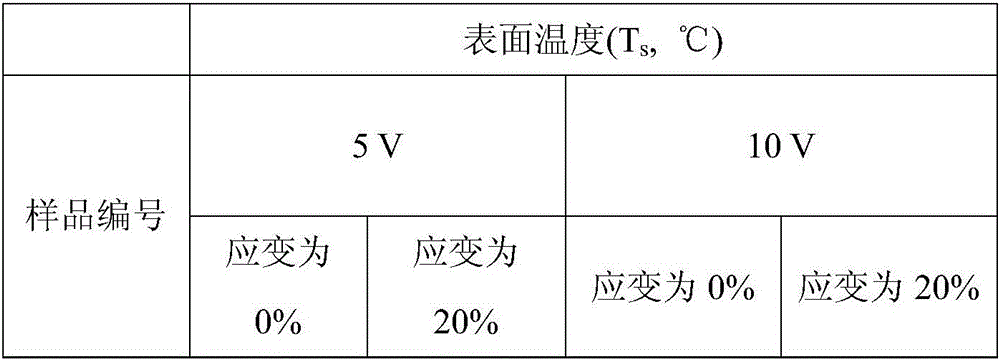

Examples

Embodiment 1

[0020] Example 1. Weigh 10 g of polydimethylsiloxane, add 1.5 g of carbon black with a diameter of 3 μm and 1.5 g of carbon fibers with a diameter of 5 μm and a length of 0.5 mm, and then ultrasonicate at room temperature for 30 minutes in an ultrasonic cell disruptor, wherein the ultrasonication is performed in batches , the regularity is ultrasound for 5 minutes, stop for 3 minutes. Then add 0.5g of cross-linking agent hydroxy silicone oil, mix evenly, pour into tetrafluoroethylene mold, and vacuumize for 20min to remove air bubbles, the vacuum degree is 0.06MPa, and then cross-link at 60°C for 2h to obtain flexible silicone rubber with mixed fillers conductor.

Embodiment 2

[0021] Example 2. Weigh 10 g of polydimethylsiloxane, add 1 g of carbon black with a diameter of 0.2 μm and 2 g of carbon fibers with a diameter of 8 μm and a length of 0.05 mm, and then perform ultrasonication at room temperature for 40 minutes in an ultrasonic cell disruptor, wherein the ultrasonication is performed in batches, The regularity is 5 minutes of ultrasound, 3 minutes off. Then add 0.05g of cross-linking agent Shuang25, mix well and pour into the tetrafluoroethylene mold, and at the same time vacuumize for 20min to remove air bubbles, the vacuum degree is 0.06MPa, and then cross-link at 60°C for 2h to obtain flexible silicone rubber with mixed fillers conductor.

Embodiment 3

[0022] Example 3 is the same as Example 2, except that 10 g of polydimethylsiloxane is weighed, and 2 g of stainless steel fibers with a diameter of 5 μm and a length of 0.05 mm are added instead of carbon fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com