Diamond-impregnated bit with double cutting structures

A diamond-impregnated, double-cutting technology, which is applied in the field of diamond-impregnated drill bits with a double-cut structure, can solve problems such as adverse effects of geological exploration and short life of diamond-impregnated drill bits, and achieve improved drill life, increased diamond content, and improved mechanical performance. The effect of drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

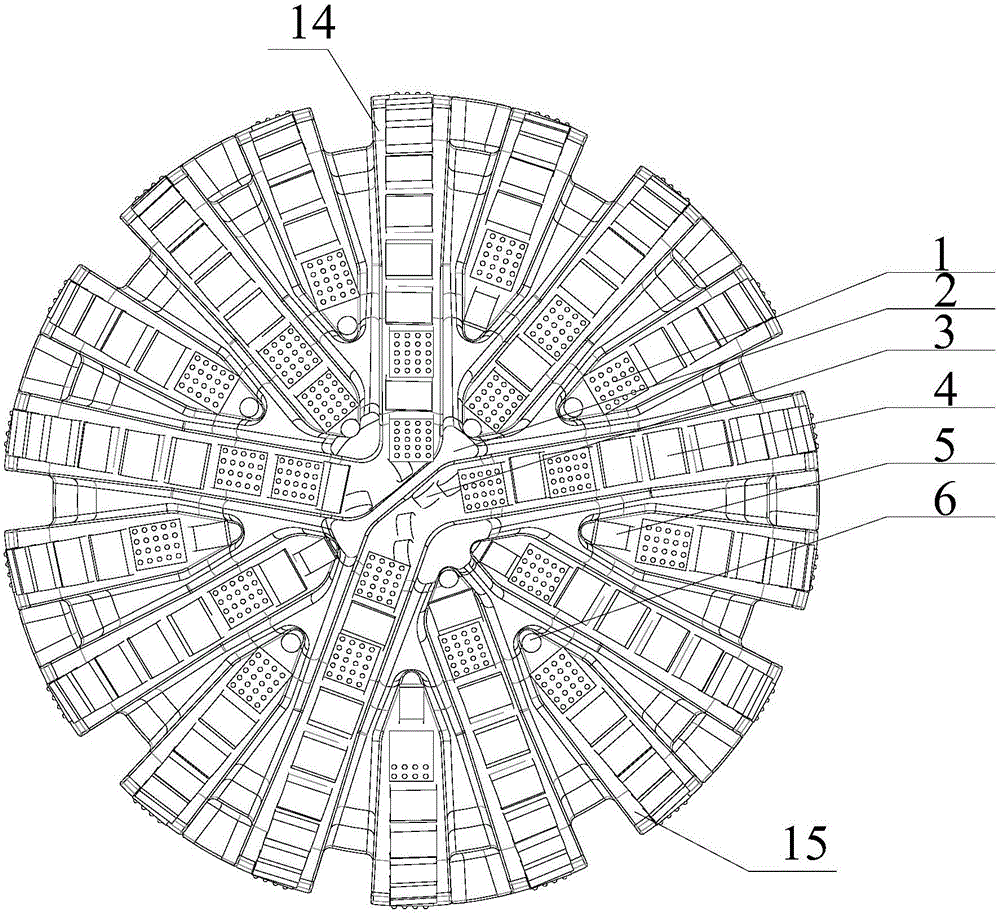

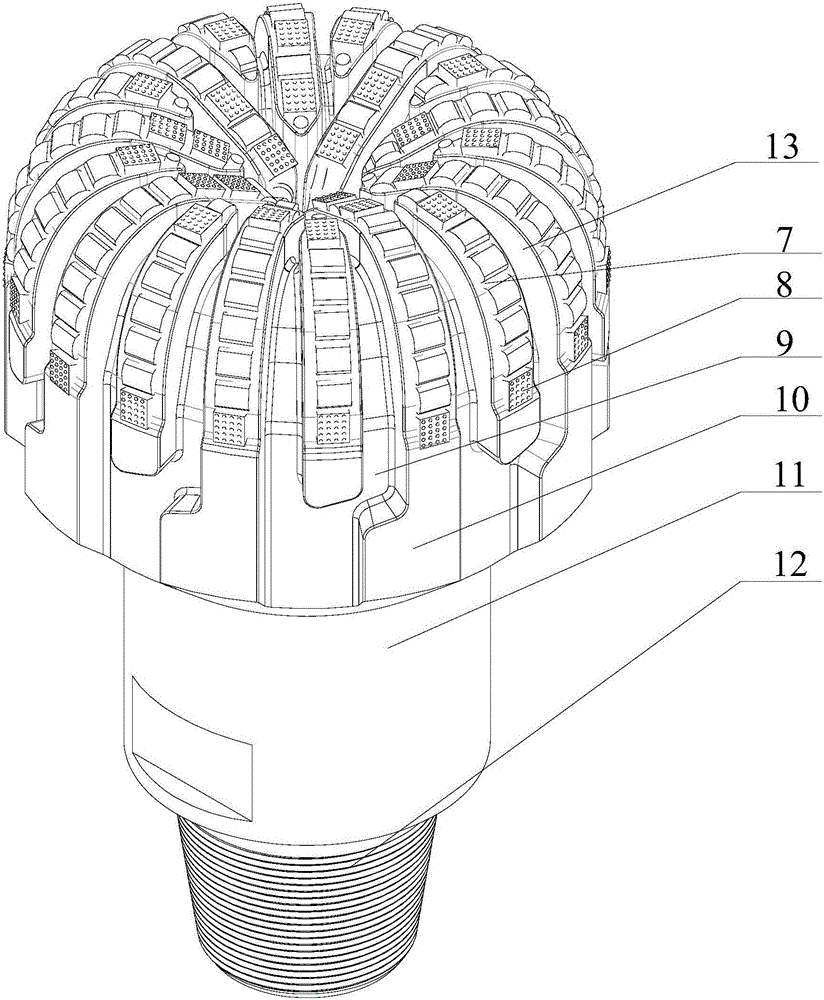

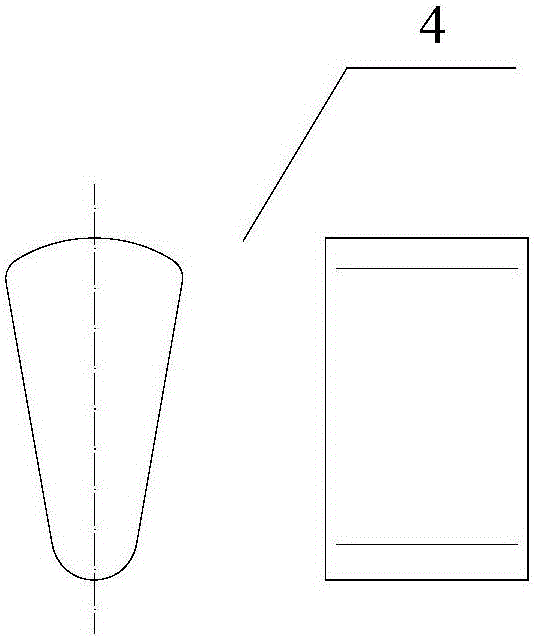

[0030] A diamond impregnated drill bit with a double-cutting structure, comprising an API joint 12, a drill body 11 connected to the API joint 12, a central water channel 2, a plurality of blades 13 and two adjacent blades 13 are arranged on the drill body 11 The water channel between them is provided with double cutting structure impregnated A1 type teeth 1, impregnated A type teeth 4, impregnated B type teeth 5, impregnated C type teeth 6 and double cutting structure impregnated teeth on the upper surface of blade 13. Inlaid A2-type tooth 8; the mixed design of double-cutting structure impregnated A1-type tooth 1, impregnated A-type tooth 4, impregnated B-type tooth 5, impregnated C-type tooth 6 and double-cutting structure impregnated A2-type tooth 8 On the blade 13, the cutting surface of the double-cutting structure impregnated A1-type tooth 1 and the double-cutting structure impregnated A2-type tooth 8 are set with large-grained natural diamonds, and small-grained diamond...

Embodiment 2

[0032] A diamond impregnated drill bit with a double-cutting structure, comprising an API joint 12, a drill body 11 connected to the API joint 12, a central water channel 2, a plurality of blades 13 and two adjacent blades 13 are arranged on the drill body 11 The water channel between them is provided with double cutting structure impregnated A1 type teeth 1, impregnated A type teeth 4, impregnated B type teeth 5, impregnated C type teeth 6 and double cutting structure impregnated teeth on the upper surface of blade 13. Inlaid A2-type tooth 8; the mixed design of double-cutting structure impregnated A1-type tooth 1, impregnated A-type tooth 4, impregnated B-type tooth 5, impregnated C-type tooth 6 and double-cutting structure impregnated A2-type tooth 8 On the blade 13, the cutting surface of the double-cutting structure impregnated A1-type tooth 1 and the double-cutting structure impregnated A2-type tooth 8 are set with large-grained natural diamonds, and small-grained diamond...

Embodiment 3

[0034]A diamond impregnated drill bit with a double-cutting structure, comprising an API joint 12, a drill body 11 connected to the API joint 12, a central water channel 2, a plurality of blades 13 and two adjacent blades 13 are arranged on the drill body 11 The water channel between them is provided with double cutting structure impregnated A1 type teeth 1, impregnated A type teeth 4, impregnated B type teeth 5, impregnated C type teeth 6 and double cutting structure impregnated teeth on the upper surface of blade 13. Inlaid A2-type tooth 8; the mixed design of double-cutting structure impregnated A1-type tooth 1, impregnated A-type tooth 4, impregnated B-type tooth 5, impregnated C-type tooth 6 and double-cutting structure impregnated A2-type tooth 8 On the blade 13, the cutting surface of the double-cutting structure impregnated A1-type tooth 1 and the double-cutting structure impregnated A2-type tooth 8 are set with large-grained natural diamonds, and small-grained diamonds...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com