Automatic sand removing dryer without damage to rhizoma coptidis

A drying machine and automatic technology, applied in the field of processing machinery, can solve the problems of insufficient drying, easy to mildew, affect the drying effect, and affect the quality of Coptis chinensis, etc., and achieve good ventilation effect, good heating effect, and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

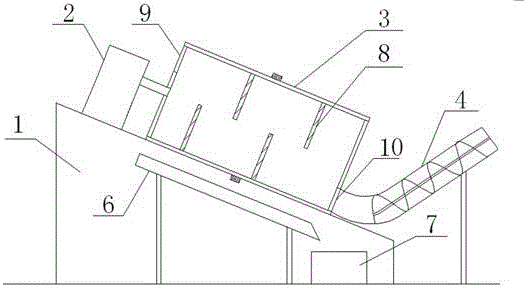

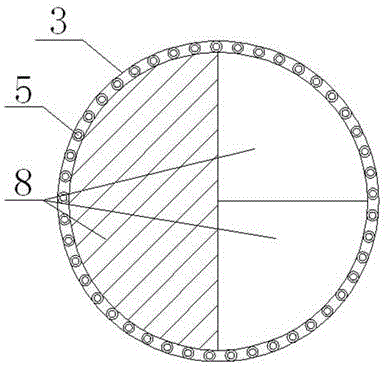

[0017] An automatic sand-removing dryer that does not damage Coptis chinensis has the advantages of simple structure, good ventilation and drying effect, no damage to Coptis chinensis, and the ability to separate soil from Coptis chinensis during drying, such as figure 1 , figure 2 As shown, the following structure is specially set up: including a frame 1 with an inclined mounting surface, a geared motor 2 arranged on the mounting surface of the frame 1, and the inclination angle of the frame 1 is 15-45 degrees, wherein the frame 1. The preferred inclination angle is 25 degrees. The main shaft of the geared motor 2 is connected to the feeding end of the tube cage 3. The tube cage 3 is a cage formed by bundling a plurality of steel tubes. Each steel tube of the tube cage 3 is provided with a The electric heating tube 5 connected to the power supply, the bottom of the tube cage 3 is provided with an inclined sand receiving table 6, and the end of the connecting sand table 6 is ...

Embodiment 2

[0019] This embodiment is further optimized on the basis of the above-mentioned embodiments, further to better realize the present invention, such as figure 1 , figure 2 As shown, the following arrangement structure is particularly adopted: the inner wall of the tube cage 3 is provided with a plurality of baffles 8 evenly distributed along the axial direction of the tube cage 3, the baffles 8 are semicircular thin plates, and the adjacent baffles 8 The phase difference on the inner wall of tube cage 3 is 90 degrees; Coptis chinensis is close to the bottom of tube cage 3 under its own gravity, and baffle plate 8 blocks Coptis chinensis to prevent it from sliding down in an inclined direction, and tube cage 3 passes through the geared motor 2 Driven to rotate, the baffle plate 8 attached to Coptis chinensis will also rotate accordingly, and slowly lose contact with Coptis chinensis, while Coptis chinensis will roll down to contact with the next baffle plate 8; this can ensure t...

Embodiment 3

[0021] This embodiment is further optimized on the basis of any of the above embodiments, further to better realize the present invention, such as figure 1 As shown, the following arrangement structure is particularly adopted: the feed end of the tube cage 3 is provided with a feed port 9 , and the discharge end of the tube cage 3 is provided with a discharge port 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com