Wind power generator stator and machining method thereof

A technology of a wind turbine and a processing method, applied in the field of electromechanical, can solve the problems of high labor intensity, low work efficiency, cumbersome processing technology, etc., and achieve the effects of simple processing method, high work efficiency and good overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

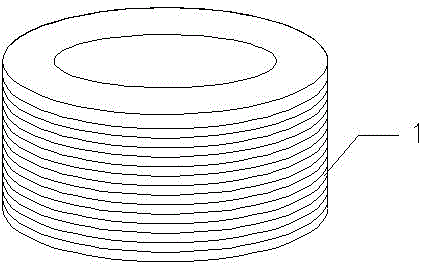

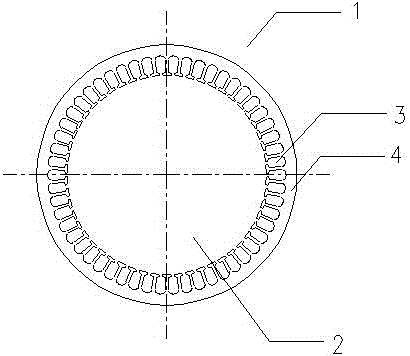

[0022] see figure 1 and figure 2 The present invention relates to a stator of a wind power generator and a processing method thereof, comprising a stator body, the stator body is formed by continuously stacking and pressing a plurality of silicon steel sheets 1, and the center of the silicon steel sheet 1 is provided with a perforation 2, The perforation 2 is used to accommodate the rotor. The silicon steel sheet 1 on the outer edge of the perforation 2 is evenly recessed with 54 slots 3. The slots 3 are used for coil winding. The silicon steel sheet 1 is composed of 4 fan-shaped silicon steel sheet units 4 It is welded, the central angle of the silicon steel sheet unit 4 is 90°, and the outer surface of the silicon steel sheet 1 is provided with a high magnetic permeability silicon plating layer.

[0023] Processing method of the present invention comprises the following steps:

[0024] Step 1. Stamping: High-speed stamping of multi-station progressive dies with a punching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com