Slip ring brush holder of wind turbine

A technology of wind turbines and slip rings, applied in wind power generation, circuits, collectors, etc., can solve problems such as weak conductivity, damage to insulating bearings, and poor mechanical properties, and achieve excellent insulation properties, increased contact area, and mechanical properties Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

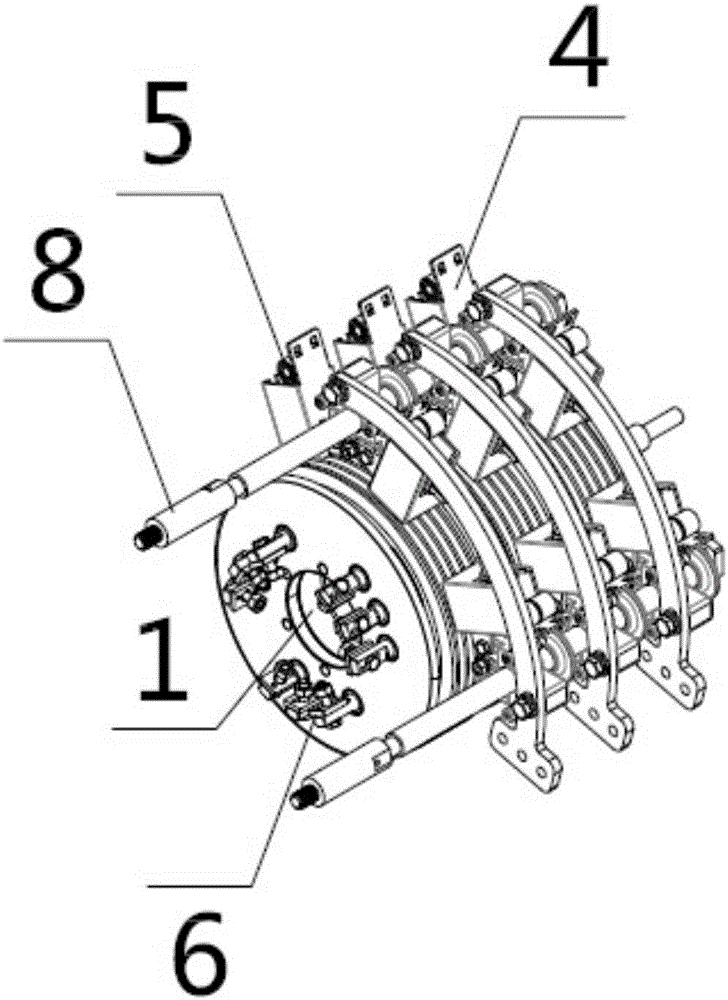

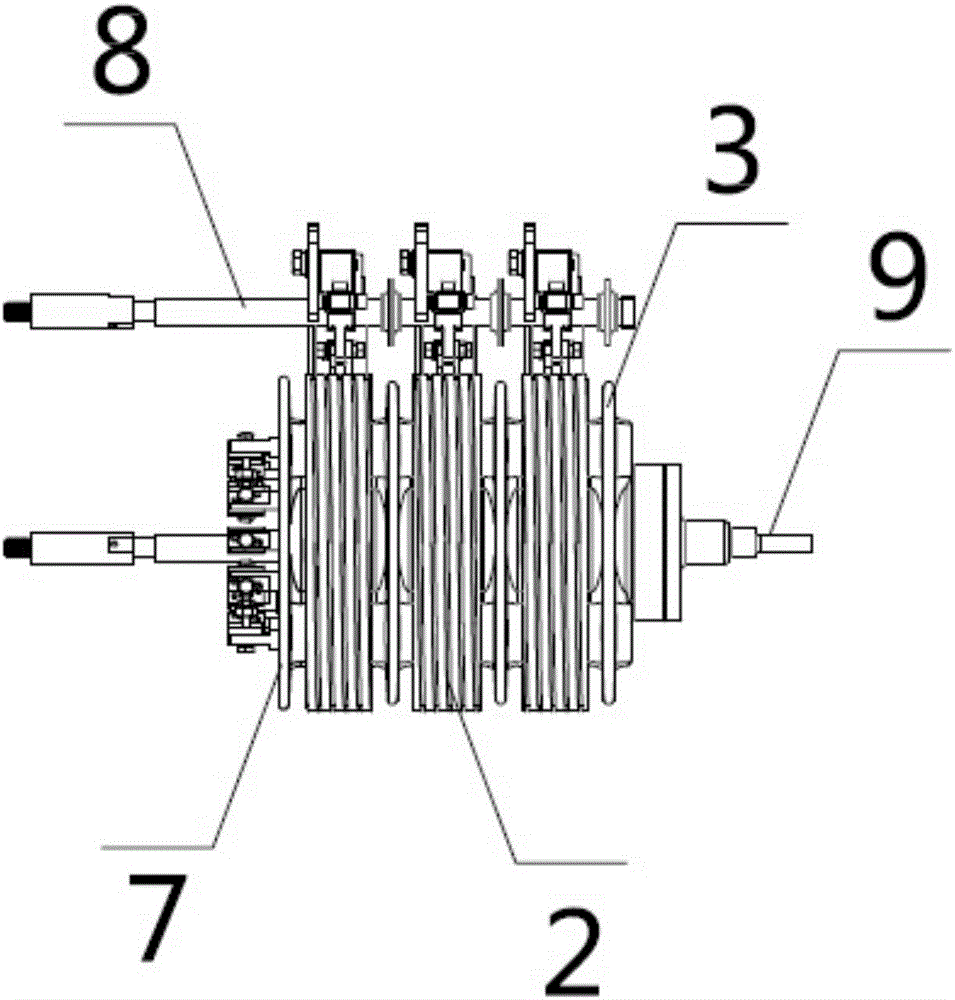

[0021] see figure 1 , figure 2 As shown, a wind power generator slip ring brush holder includes a slip ring, a main brush holder 4, a brush holder device and a copper terminal 6 installed on the slip ring, and the slip ring is composed of an insulator 3 and a main slip ring 2 are staggeredly installed on the slip ring shaft cylinder 1, the main brush holder 4 is installed on the brush holder device through a support rod 8 to contact with the main slip ring 2, and the main brush holder 4 is installed with a constant The compression spring 5 also includes an insulating end cap 7 installed on the upper end of the slip ring, and the insulator 3 is molded from SMC material.

[0022] Further, the diameter of the constant pressure spring 5 is greater than 23.5mm and less than or equal to 24.3mm, the heat treatment adopts vacuum quenching...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com