Cobblestone steamed bread making method

A production method and stone technology, applied in baking, dough processing, baked food, etc., can solve problems such as easy to be affected by moisture, single taste, fragile stone buns, etc., achieve a salty taste, improve the taste, and solve the fear of extrusion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

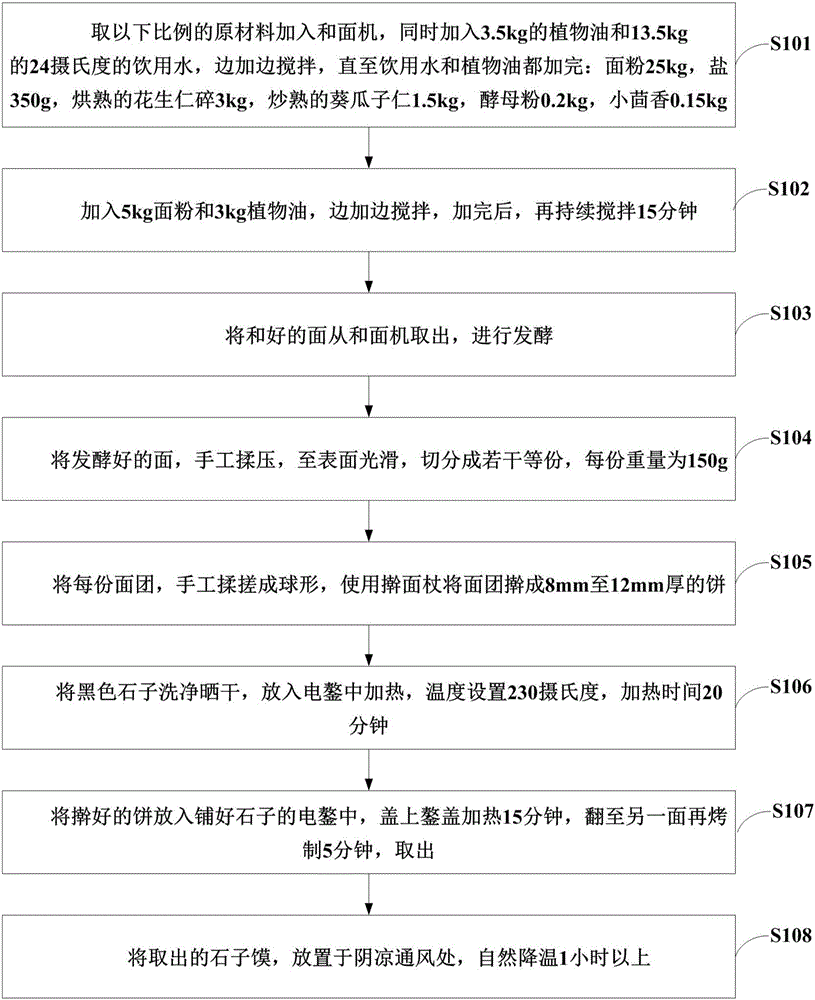

[0031] Step 1. Take 2000 parts of all-purpose flour, 30 parts of salt, 250 parts of roasted peanut kernels, 100 parts of fried sunflower seeds, 14 parts of yeast powder, and 12 parts of cumin, and add them to the dough mixer, and add them at a uniform speed 300 parts of vegetable oil and 1200 parts of drinking water at 15 degrees Celsius are added while stirring until drinking water and vegetable oil are all added.

[0032] Step 2, add 400 parts of flour and 250 parts of vegetable oil, stir while adding, and continue stirring for 10 minutes after adding;

[0033] Step 3. Take out the reconciled noodles from the dough mixer, and ferment for 40 minutes at a room temperature of 24 degrees Celsius; drying;

[0034] Step 4. Knead the fermented noodles by hand until the surface is smooth, and cut it into several equal parts, each weighing 150g;

[0035] Step 5. Knead each piece of dough into a ball by hand, and use a rolling pin to roll the dough into a cake shape with a thickness...

Embodiment 2

[0040] On the basis of Example 1, step 1 takes 3000 parts of flour, 340 parts of salt, 350 parts of roasted peanut kernels, 200 parts of fried sunflower seeds, 24 parts of yeast powder, and 18 parts of fennel. Noodle machine, add 400 parts of vegetable oil and 1500 parts of drinking water at 30 degrees Celsius at a uniform speed at the same time, stir while adding, until drinking water and vegetable oil are all added.

[0041] Step 2, add 600 parts of flour and 350 parts of vegetable oil, stir while adding, and continue stirring for 20 minutes after adding;

[0042] Step 3. Take out the reconciled noodles from the dough mixer, and ferment for 60 minutes at a room temperature of about 24 degrees Celsius; during the fermentation, take stones (about 10-15mm in diameter with a smooth surface) to wash and dry;

[0043] Step 4. Knead the fermented noodles by hand until the surface is smooth, and cut into several equal parts, each weighing about 150g;

[0044] Step 5. Knead each pie...

Embodiment 3

[0049] On the basis of Example 1, step 1 takes 2500 parts of flour, 35 parts of salt, 300 parts of roasted ground peanuts, 150 parts of fried sunflower seeds, 20 parts of yeast powder, and 15 parts of cumin. Noodle machine, add 350 parts of vegetable oil and 1350 parts of drinking water at a room temperature of about 24 degrees Celsius at the same time, and stir while adding until the drinking water and vegetable oil are all added.

[0050] Step 2, add 500 parts of flour and 300 parts of vegetable oil, and continue stirring for 15 minutes after adding;

[0051] Step 3. Take out the reconciled noodles from the dough mixer, and ferment for 50 minutes at a room temperature of about 24 degrees Celsius; during the fermentation period, take stones (about 10-15mm in diameter with a smooth surface) to wash and dry in the sun ;

[0052] Step 4. Knead the fermented noodles by hand until the surface is smooth, and cut into several equal parts, each weighing 150g;

[0053] Step 5. Knead...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com