System and method for automatically preparing flocculant solution

An automatic preparation and coagulant technology, which is applied in the general control system, control/regulation system, dissolution system, etc., can solve the problems of inability to take into account the coagulant preparation, consume manpower and material resources, and unfavorable power plant management, etc., and achieve good practical application value , Reduce labor intensity and save capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

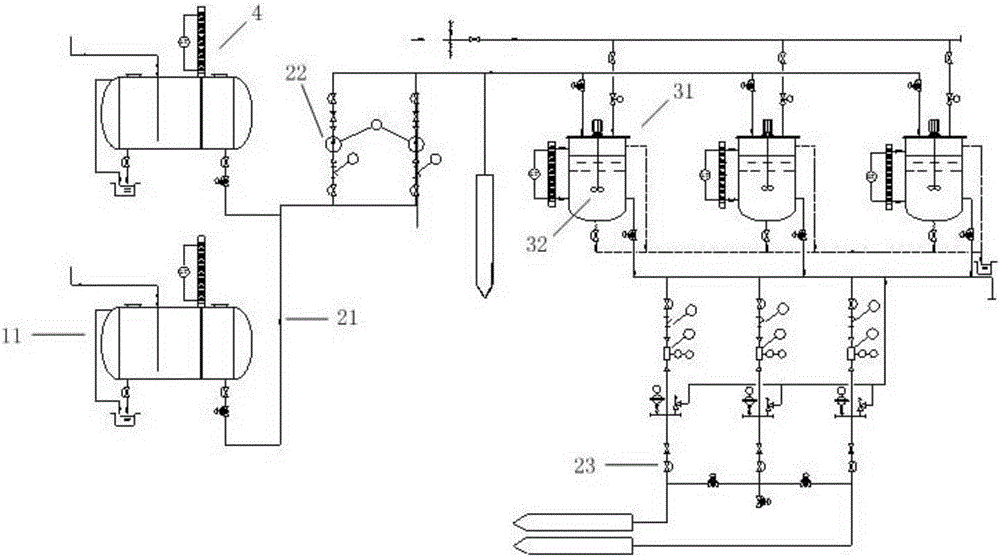

[0047] Embodiment 1: A system and method for automatically preparing coagulant solution

[0048] It includes a drug storage system, a drug dissolving system, a delivery system and a DCS control system. The DCS control system is electrically or pneumatically connected to the drug storage system, drug dissolving system and delivery system; the liquid outlet of the drug storage system is connected to the solution via the delivery system. The drug system is connected to the liquid inlet, and the drug dissolving system is also connected to the water source; the DCS control system electrical connection or gas connection is provided on the drug storage system liquid outlet, the drug dissolving system inlet and outlet, the drug dissolving system water inlet and the delivery system. Connected valves and manual valves. Manual valves and valves connected electrically or pneumatically to the DCS control system are connected in series.

[0049] Under normal operation, the manual valve is ...

example 1

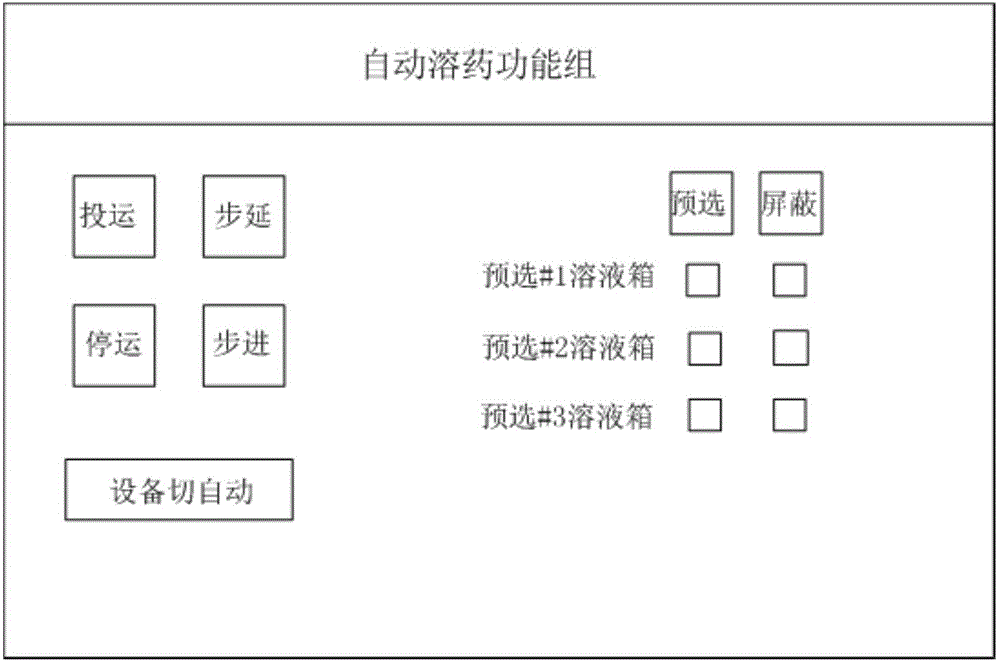

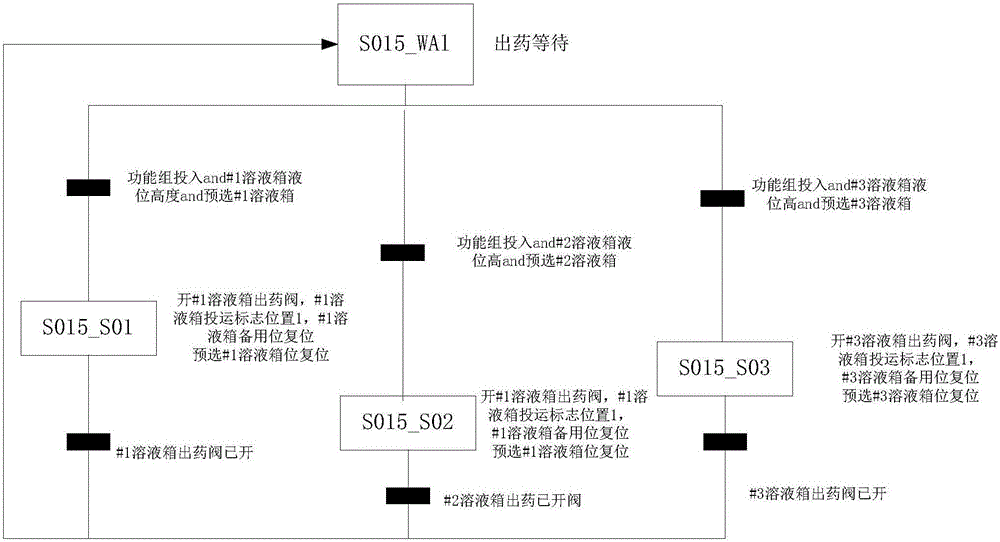

[0065] There are two coagulant raw material liquid drug storage tanks, two coagulant delivery pumps, and three solution tanks in the polymer aluminum dissolving device of a certain factory. Usually, one of the solution tanks is selected for operation, and the other two are used as backup. According to the needs, select the drug storage tank and coagulant delivery pump to be operated on the DCS program operation interface in advance, shield one of the unused solution tanks, and set the low liquid level of the operating solution tank to 0.16m. When it is lower than the set low liquid level value, the DCS controls the solution tank to automatically switch to the standby solution tank for operation;

[0066] According to the turbidity of the raw water, set the filling height of the coagulant raw material solution to 0.19m, and set the amount of water to be added until the liquid level of the solution tank reaches 1.00m. The selected transfer pump pumps the coagulant raw material l...

example 2

[0069] There are two coagulant raw material liquid drug storage tanks, two coagulant delivery pumps, and three solution tanks in the polymer aluminum dissolving device of a certain factory. Usually, one of the solution tanks is selected for operation, and the other two are used as backup. According to the needs, select the drug storage tank and coagulant delivery pump to be operated on the DCS program operation interface in advance, shield one of the unused solution tanks, and set the low liquid level of the operating solution tank to 0.16m. When it is lower than the set low liquid level value, the DCS controls the solution tank to automatically switch to the standby solution tank for operation;

[0070] According to the turbidity of the raw water, set the filling height of the coagulant raw material solution to 0.25m, and set the amount of water to be added until the liquid level of the solution tank reaches 1.00m. The selected transfer pump pumps the coagulant raw material l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com