Method for preparing carbon fiber reinforced silicon carbide (Csf/C-SiC) composite material

A composite material and carbon fiber technology, which is applied in the field of preparation of carbon fiber reinforced silicon carbide (Csf/C-SiC) composite materials, can solve the problems of decreased mechanical properties and material density, and achieve improved mechanical properties and increased densification , Improve the effect of high temperature performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

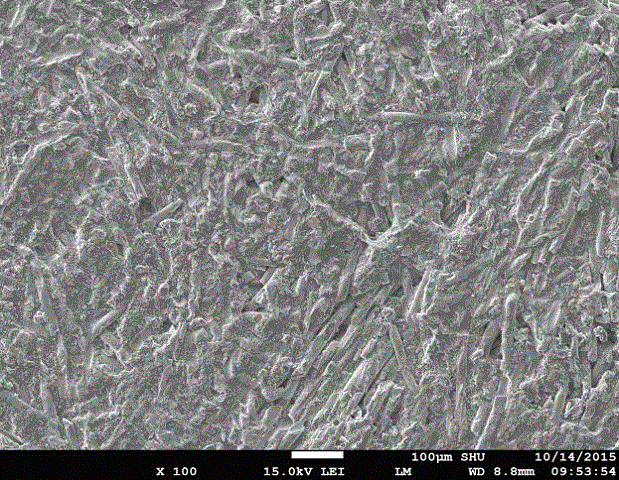

Image

Examples

Embodiment

[0022] A method for preparing a carbon fiber reinforced silicon carbide (Csf / C-SiC) composite material using polycarbosilane as a precursor, the specific steps of which are:

[0023] (1). Soak 9g of 3-30mm chopped polyacrylonitrile-based carbon fiber in dimethyl sulfoxide solution (3vol%) for 2h to remove glue;

[0024] (2). The chopped carbon fibers after degumming are strongly dispersed to obtain dispersed chopped carbon fibers;

[0025] (3). Weigh 16g of silicon carbide SiC powder and place it in ethanol solution, and add 1.6g~4g of polycarbosilane, 1.6g of silicon powder, and 0.8g of aluminum powder to the solution in turn under stirring , 0.096g of boron powder, after mixing uniformly, obtain ethanol suspension;

[0026] (4). Heat the homogeneously mixed ethanol suspension obtained in the above step (3) to 150°C and evaporate until the solvent is completely volatilized to obtain a block mixture. Grind the block mixture to a sieve below 200 mesh to obtain a mixture powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com