Preparation method and use of phosphate anion surface imprinted polymer

A technology of surface imprinting and anion, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of incomplete elution of template ions, slow mass transfer, low adsorption capacity, etc., and achieve good adsorption stability and good selectivity and regeneration performance, the effect of superior adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

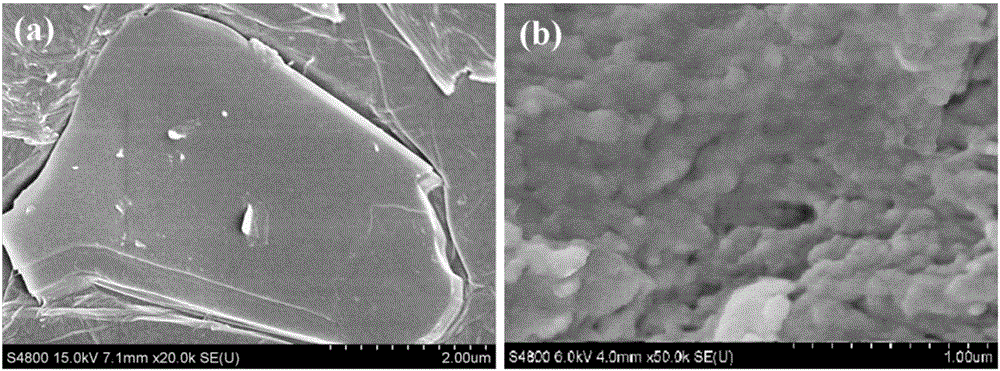

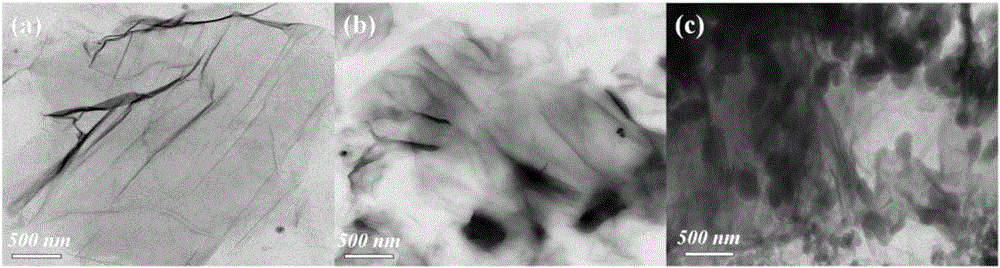

[0028] (1) Preparation of La(III)-modified graphene oxide (GO-La)

[0029] Take a 250mL beaker, ultrasonically dissolve 50mg GO in 100mL water, add 10mL La(III) solution (containing 12.25mg LaCl 3 ·6H 2O), continued stirring reaction 12h. Centrifuge, wash with a large amount of water for several times, and dry in a vacuum oven at 40°C for 24 hours to obtain GO-La.

[0030] (2) Vinylation modification of La(III)-modified graphene oxide (GO-La-MPS)

[0031] Take a round bottom flask, add 200mg GO-La, 5mL MPS and 50mL ethanol respectively, and sonicate for 20 minutes. The mixture was placed in a 50 °C oil bath while magnetically stirring (500 rpm) for 12 h. After cooling to room temperature, it was centrifuged and washed three times with ethanol, and the obtained GO-La-MPS was vacuum-dried at 40 °C for 24 h.

[0032] (3) Preparation of phosphate anion imprinted polymer (GO-La-IIP)

[0033] Take a round bottom flask, add 30mL ethanol and 10mL ultra-light water (DDW), stir ma...

Embodiment 2

[0041] (1) Preparation of La(III)-modified graphene oxide (GO-La)

[0042] Take a 250mL beaker, ultrasonically dissolve 100mg GO in 100mL water, add 10mL La(III) solution (containing 24.5mg LaCl 3 ·6H 2 O), continued to stir for 12h. Centrifuge, wash with a large amount of deionized water, place in a vacuum oven at 40°C, and dry for 24 hours to obtain GO-La.

[0043] (2) Vinylation modification of La(III)-modified graphene oxide (GO-La-MPS)

[0044] Take a round bottom flask, add 200mg GO-La, 10mL MPS and 50mL ethanol respectively, and sonicate for 20 minutes. The mixture was placed in a 50 °C oil bath, magnetically stirred (500 rpm) for 12 h. After cooling to room temperature, it was centrifuged and washed three times with ethanol, and the obtained GO-La-MPS was vacuum-dried at 40 °C for 24 h.

[0045] (3) Preparation of phosphate anion imprinted polymer (GO-La-IIP)

[0046] Take a round bottom flask, add 35mL ethanol and 10mL ultra-light water (DDW), stir magnetically ...

Embodiment 3

[0052] (1) Preparation of La(III)-modified graphene oxide (GO-La)

[0053] Take a 250mL beaker, ultrasonically dissolve 200mg GO in 100mL water, add 10mL La(III) solution (containing 49mg LaCl 3 ·6H 2 O), continued stirring reaction 12h. Centrifuge, wash with a large amount of water for several times, and dry in a vacuum oven at 40°C for 24 hours to obtain GO-La.

[0054] (2) Vinylation modification of La(III)-modified graphene oxide (GO-La-MPS)

[0055] Take a round bottom flask, add 200mg GO-La, 20mL MPS and 50mL ethanol respectively, and sonicate for 20 minutes. The mixture was placed in a 50 °C oil bath while magnetically stirring (500 rpm) for 12 h. After cooling to room temperature, it was centrifuged, washed three times with ethanol, and the obtained GO-La-MPS was vacuum-dried at 40 °C for 24 h.

[0056] (3) Preparation of phosphate anion imprinted polymer (GO-La-IIP)

[0057]Take a round bottom flask, add 40mL ethanol and 10mL ultra-light water (DDW), stir magnet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com