Antistatic composite nano material film and preparation method thereof

A technology of material film and composite film, which is applied in the field of polymer composite film preparation, can solve the problems of easy permeation, limit the application of TPU film material, and cause danger, etc., and achieve the effect of simple process, wide prospects and uses, and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A method for preparing an antistatic composite nanomaterial film, the specific steps are:

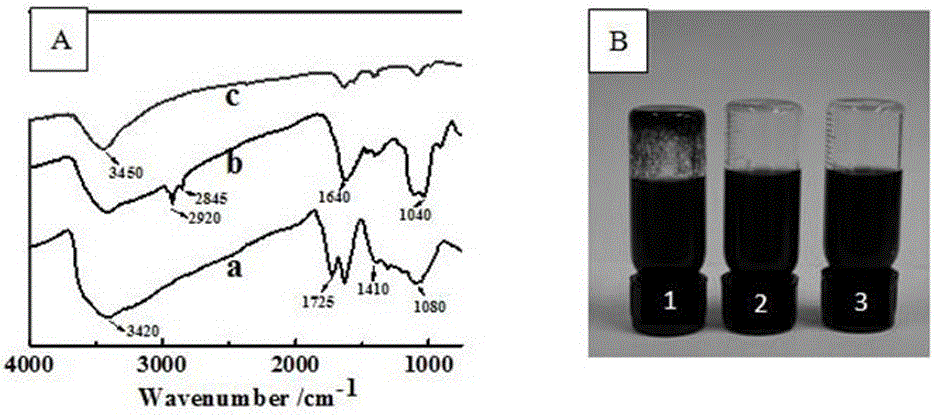

[0023] (1) Preparation of GONRs: First, 180 mL of concentrated H 2 SO 4 Slowly added to the round bottom flask and stirred, then 20 mLH 3 PO 4 Slowly drop in, mix evenly at a certain speed, slowly add 1 g MWCNTs and stir for 30 min until uniform, then add 6 g KMnO 4 Slowly added to the above mixture; the above reaction system was stirred in an oil bath at 50 °C for 24 h, then cooled to room temperature, and then poured into a solution containing 10 mL H 2 o 2 500 mL of deionized water was stirred in an ice bath for 1 h. At this time, the solution turned dark green, indicating that the reaction was complete. Then, an appropriate amount of HCl was added and centrifuged until neutral, and finally dried in a freeze dryer to obtain GONRs;

[0024] (2) Preparation of FGONRs: 500 mg GONRs were dissolved in a mixed solution of 250 mL deionized water and 200 mL absolute ethanol, and ...

Embodiment 1

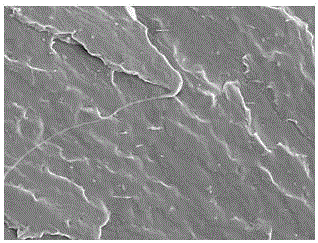

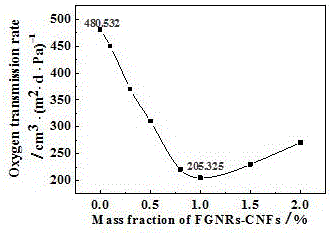

[0030] Take 15 g of fully dried TPU and swell in 60 mL of DMF at 60°C for 24 h to obtain a viscous TPU solution; then take a DMF solution containing 0.06 g of FGNRs according to the volume ratio, add 0.015 g of CNFs and ultrasonicate at 100 W for 1 h to form FGNRs:CNFs 4:1 homogeneously mixed solution, mixed with swollen TPU; mechanically stirred for 5 h, then the mixture was ultrasonicated for 1 h to remove air bubbles, then coated with a 0.08 mm film on a film coater, and finally in a dry box Dry at 70°C for 24 h until the solvent evaporates completely to obtain a 0.5wt% FGNRs-CNFs / TPU composite film.

Embodiment 2

[0032]Take 37.5 g of fully dried TPU and swell in 60 mL of DMF at 60 °C for 24 h to obtain a viscous TPU solution; then take a DMF solution containing 0.06 g of FGNRs according to the volume ratio, add 0.015 g of CNFs and ultrasonicate at 100 W for 1 h to form FGNRs:CNFs 4:1 homogeneously mixed solution, mixed with swollen TPU; mechanically stirred for 5 h, then the mixture was ultrasonicated for 1 h to remove air bubbles, then coated with a 0.08 mm film on a film coater, and finally in a dry box Dry at 70°C for 24 h until the solvent evaporates completely to obtain a 0.2wt% FGNRs-CNFs / TPU composite film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com