Method for extracting tungsten from scheelite

A scheelite and roasting technology, applied in the field of tungsten extraction, can solve problems such as low production efficiency and safety problems, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

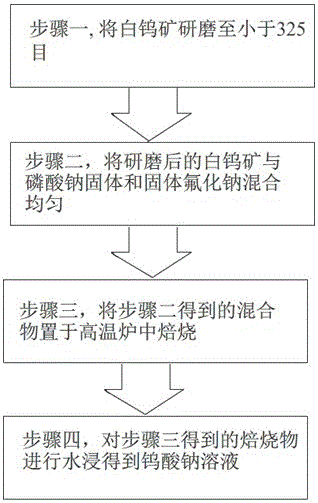

Method used

Image

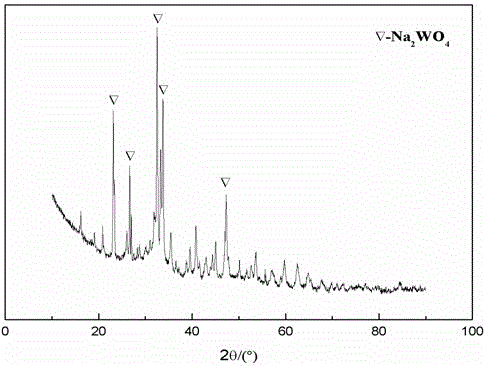

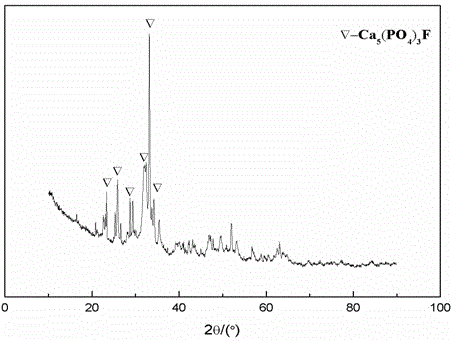

Examples

Embodiment 2

[0030] Embodiment 2: scheelite contains 70.32% WO 3 . The weight of scheelite is 100g, 2 times the theoretical amount of sodium phosphate, 2 times the theoretical amount of calcium fluoride, roasted at 500°C for 2 hours, the roasted product is stirred and leached with water, the liquid-solid ratio is 3:1, the temperature is room temperature, kept for 2 hours, filtered , washed with water, dried, the slag contains insoluble WO 3 It is 18.57%, and the decomposition rate reaches 57.31%.

Embodiment 3

[0031] Embodiment 3: scheelite contains 30.35% WO 3 . The weight of scheelite is 80g, 3.5 times the theoretical amount of sodium phosphate, roasted at 850°C for 2 hours, 6 times the theoretical amount of calcium fluoride, the roasted product is stirred and leached with water, the liquid-solid ratio is 4:1, the temperature is 50°C, kept for 3 hours, filtered , washed with water, dried, the slag contains insoluble WO 3 It is 1.37%, and the decomposition rate reaches 96.39%.

Embodiment 4

[0032] Embodiment 4: scheelite contains 56.32% WO 3 . The weight of scheelite is 120g, 2.5 times the theoretical amount of sodium phosphate, 5 times the theoretical amount of calcium fluoride, roasted at 650°C for 3 hours, the roasted product is stirred and leached with water, the liquid-solid ratio is 6:1, the temperature is 90°C, kept for 4 hours, filtered , washed with water, dried, the slag contains insoluble WO 3 It is 1.09%, and the decomposition rate reaches 98.48%.

[0033] From the above test data, it can be concluded that the method for extracting tungsten from scheelite provided by the present invention, compared with the existing process of decomposing scheelite, can react under normal pressure environment, and it is easy to realize continuous production and operation. It is more convenient and safe, and the insoluble WO contained in the slag 3 extremely low.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com