Treatment method of stainless steel pickling sludge

A technology of pickling sludge and treatment method, applied in the direction of improving process efficiency, can solve problems such as hidden dangers, environmental pollution, occupation of land resources, etc., and achieve the effect of harmless treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

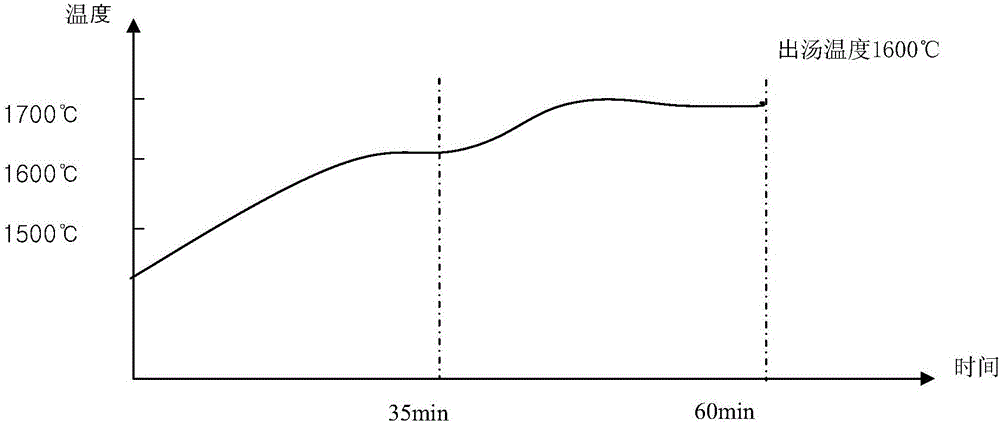

[0029] Embodiment 1-4, take electric furnace one-time loading 100 tons of main raw materials as an example.

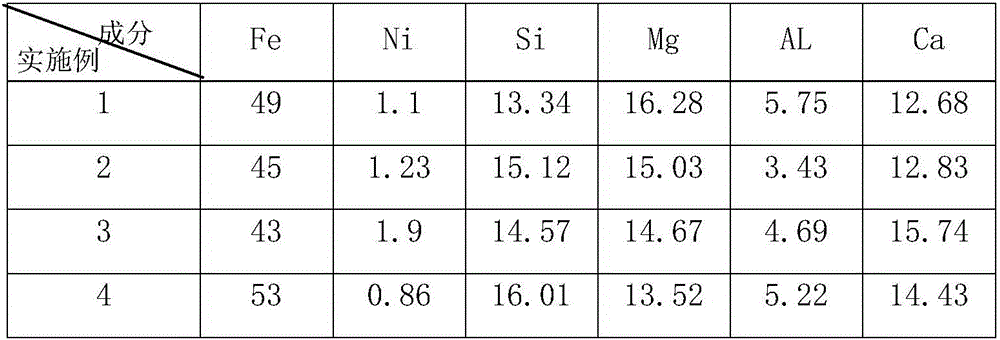

[0030] The following table 1 Be the main component and content (mass percentage) of stainless steel pickling sludge:

[0031]

[0032] The following table 2 To load the raw materials and content into the electric furnace, the mixture is mixed at a weight ratio of 1:9 (unit: ton):

[0033]

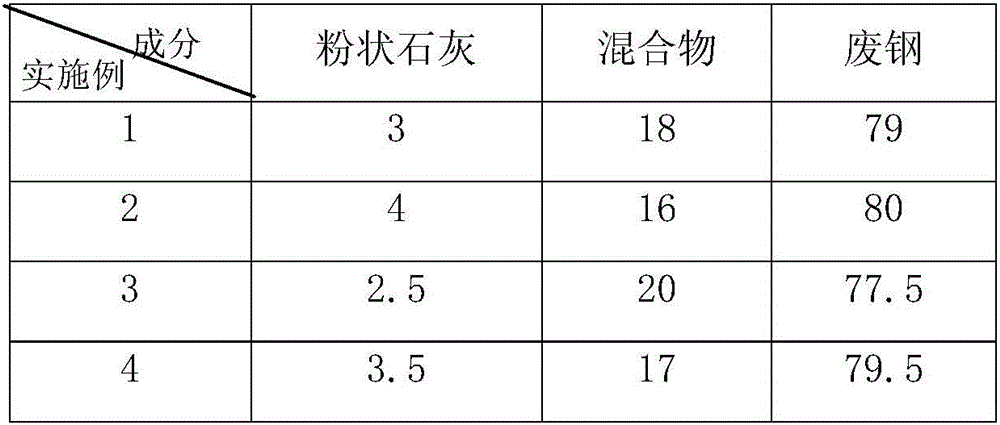

[0034] The following table 3 Main composition and content (mass percentage) of the obtained ferronickel alloy finished product for smelting:

[0035]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com