Preparation method and application of intelligent anticorrosion coating

An anti-corrosion coating and intelligent technology, applied in coatings, metal material coating processes, liquid chemical plating, etc. Cathodic reaction, low manufacturing cost, effect of protecting metal materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

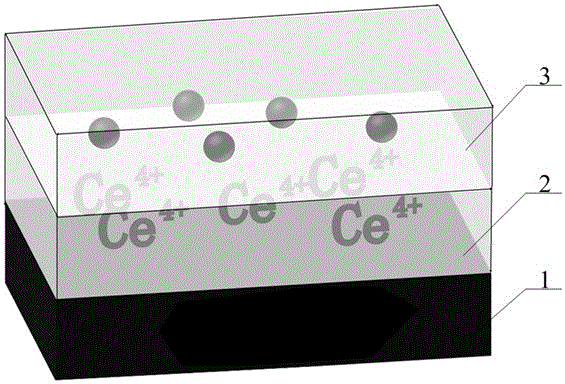

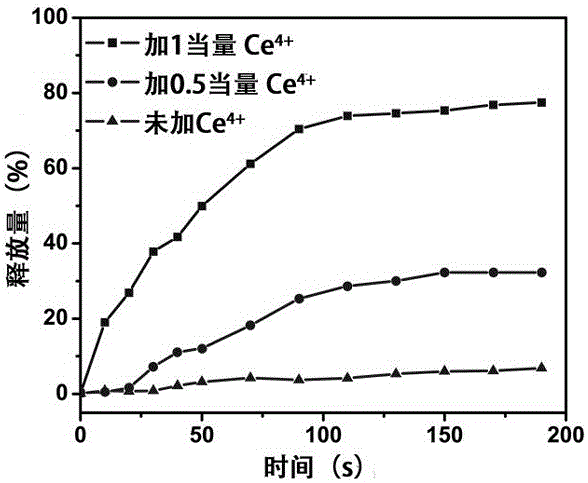

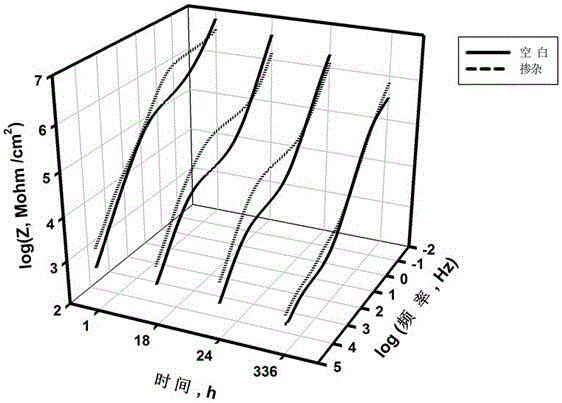

Image

Examples

Embodiment 1

[0043] Step 1: Preparation of silica mesoporous microspheres (MSNs).

[0044] 1. Mix 1.0g cetyltrimethylammonium bromide (CTAB), 3.5mL 2mol / L sodium hydroxide (NaOH) solution and 480mL water, and heat to 80 under mechanical stirring (500 rpm) ℃, reflux for 1h to fully activate cetyltrimethylammonium bromide;

[0045] 2. In the mixed solution of step 1, add 5.0mL ethyl orthosilicate (TEOS) dropwise, under vigorous stirring, a white solid will form within 10 minutes. After reacting at 80°C for 2 hours, filter it while it is hot and use water and methanol to fully Wash the product and vacuum dry it at 70°C to obtain a solid;

[0046] 3. Weigh 1.0g of dry solid, ultrasonically disperse it in a mixed solution of 150mL methanol and 10mL concentrated hydrochloric acid, reflux for 6h at 65℃, centrifuge it, wash thoroughly with water and methanol successively, and dry it under vacuum at 70℃ to obtain mesoporous silica Microspheres (MSNs).

[0047] Step two: modifying the surface of the mesop...

Embodiment 2

[0063] Step 1: Preparation of silica mesoporous microspheres (MSNs).

[0064] 1. Mix 1.0g cetyltrimethylammonium bromide (CTAB), 3.5mL 2mol / L sodium hydroxide (NaOH) solution with 480mL water, and heat to 90 under mechanical stirring (500 rpm) ℃, reflux for 1.5h to fully activate cetyltrimethylammonium bromide;

[0065] 2. In the mixed solution of step 1, add 5.0 mL of ethyl orthosilicate (TEOS) dropwise, under vigorous stirring, a white solid will form within 10 minutes. After reacting at 90°C for 2.5 hours, filter while hot, and use water and methanol successively Thoroughly clean the product, vacuum dry at 70°C to obtain a solid;

[0066] 3. Weigh 1.0g of dry solid, ultrasonically disperse it in a mixed solution of 100mL methanol and 10mL concentrated hydrochloric acid, reflux at 70℃ for 4h, centrifuge, and wash thoroughly with water and methanol successively, and vacuum dry at 70℃ to obtain mesoporous silica Microspheres (MSNs).

[0067] Step two: modifying the surface of the me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com