Method for preparing unbleached pulp of raw material of egg trays with tail pulp of crop straws

A technology for crop straw and egg trays, which is applied in the fields of cellulose raw material pulping, fiber raw material processing, non-woody plant/crop pulp, etc., to achieve good economic benefits, eliminate toxic and side effects, and facilitate wide-scale popularization and use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

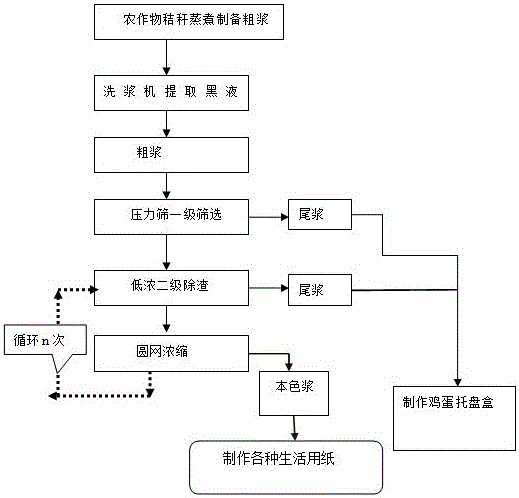

[0027] The concrete processing method of the inventive method is as follows:

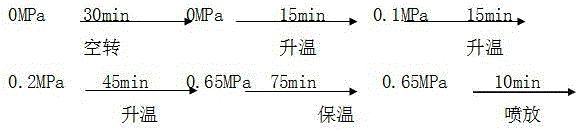

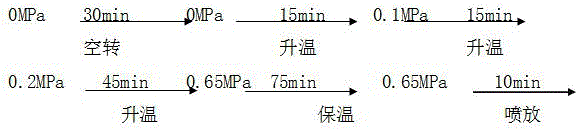

[0028] 1. Straw cooking to prepare coarse pulp: Straw raw materials, such as wheat straw, rice straw, corn straw, etc., pass through the feeding part of the 12T grass cutter, enter the knife roller part and cut to a length of 20-40mm, and enter the eight-roller horn through the discharge conveyor belt. Dust removal equipment, qualified grass flakes are transported to the first and second presoakers by scrapers, mixed evenly with cooking liquid (sodium hydroxide), and then loaded into steaming balls. Seal the ball cover and carry out idling, heating, and heat preservation. The cooking pressure is controlled within the range of 0-0.65MPa, and the steam is released and sprayed. The coarse slurry after cooking is sprayed into the spray chamber.

[0029] 2. Extraction of black liquor by pulping machine: the coarse pulp in the spray bin is then fed into the single-screw squeezer through the feeding screw ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com