Method for erecting large-span lower chord variable truss high continuous steel trussed beam cantilever

A technology of large-span and steel truss girders, applied in bridge construction, erection/assembly of bridges, bridges, etc., can solve problems such as the lack of navigation conditions for large-tonnage ships, achieve great promotion value, ensure quality, and concentrate assembly operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Referring to the accompanying drawings, a method for cantilever erection of a continuous steel truss girder with variable chord height and large span, includes the following construction steps:

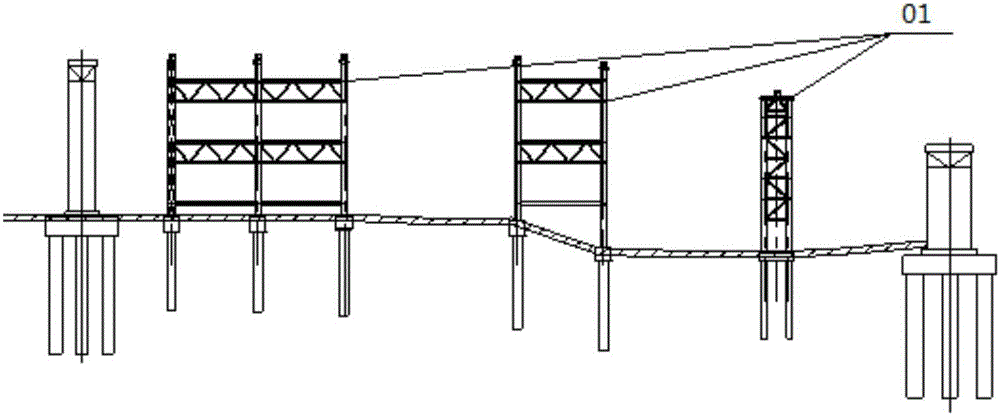

[0044] 1) First, set up temporary steel truss-type assembled support 01 at the position of the side-span bridge on both sides, as a temporary support pier for the erection of side-span steel beams. The internodes are arranged continuously, and the temporary buttresses behind are arranged intermittently;

[0045] 2) Install a steel beam lifting device 02 near the side pier for vertical transportation of the bars and assembly of the first three internodes of the side span;

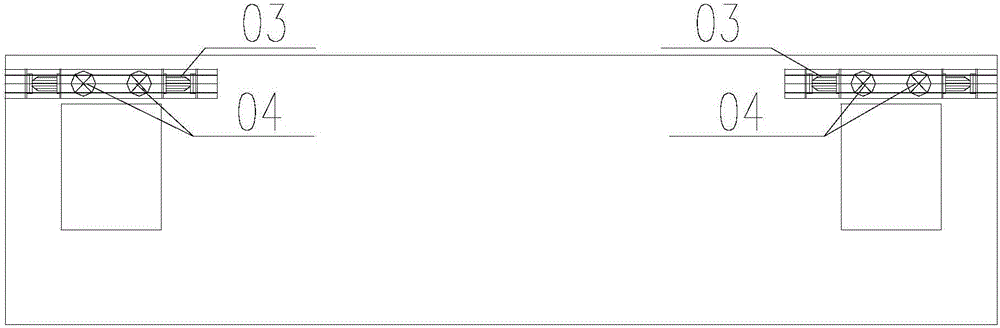

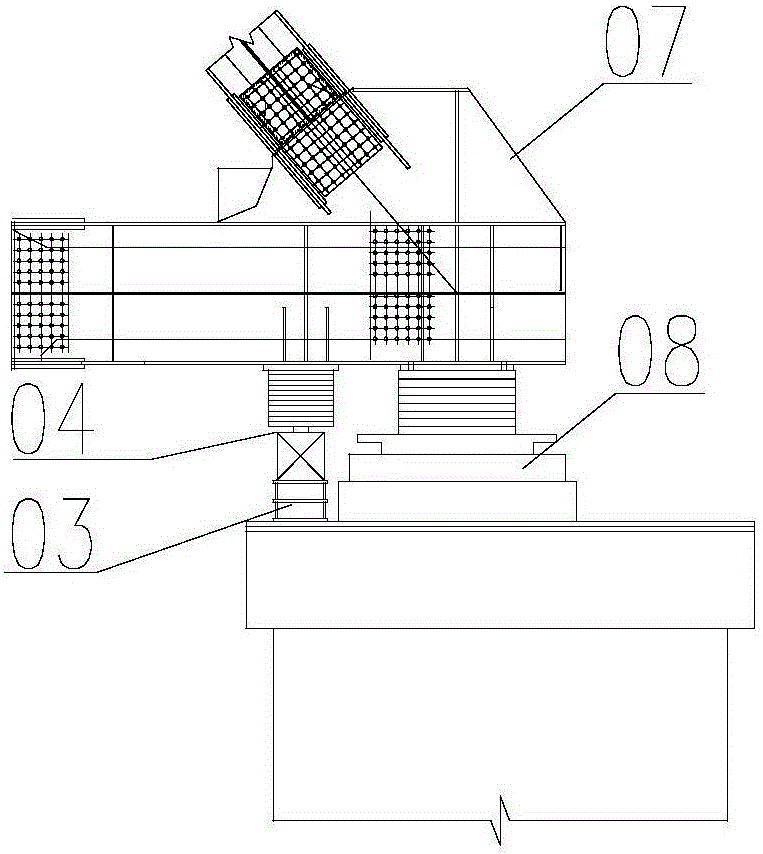

[0046] 3) The pier tops of the permanent piers, side piers and main piers are respectively arranged with a pier top layout system. The pier top layout system includes a vertical and horizontal deviation correction device 03 and a vertical jacking device 04, which are used to vertically and horizontally adjust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com