Integral clip-type anchor structure device and assembly method thereof

An integrated, clip-type technology, applied in the direction of basic structure engineering, building construction, bridge parts, etc., can solve the problem of small bonding area between FRP tendons or strands and anchoring medium, low sliding friction and mechanical bite force, Problems such as large geometric dimensions, to achieve high anchorage efficiency, avoid early fracture, and reduce stress peaks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

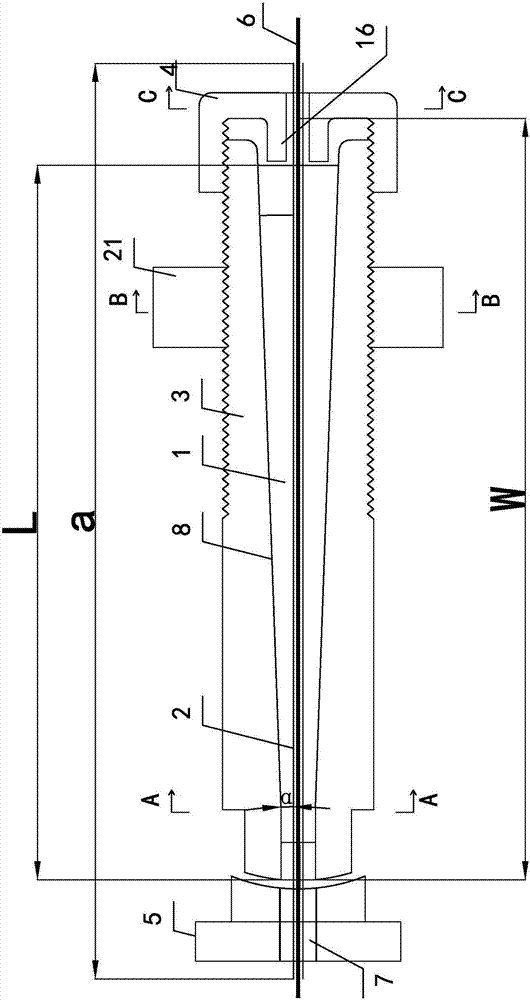

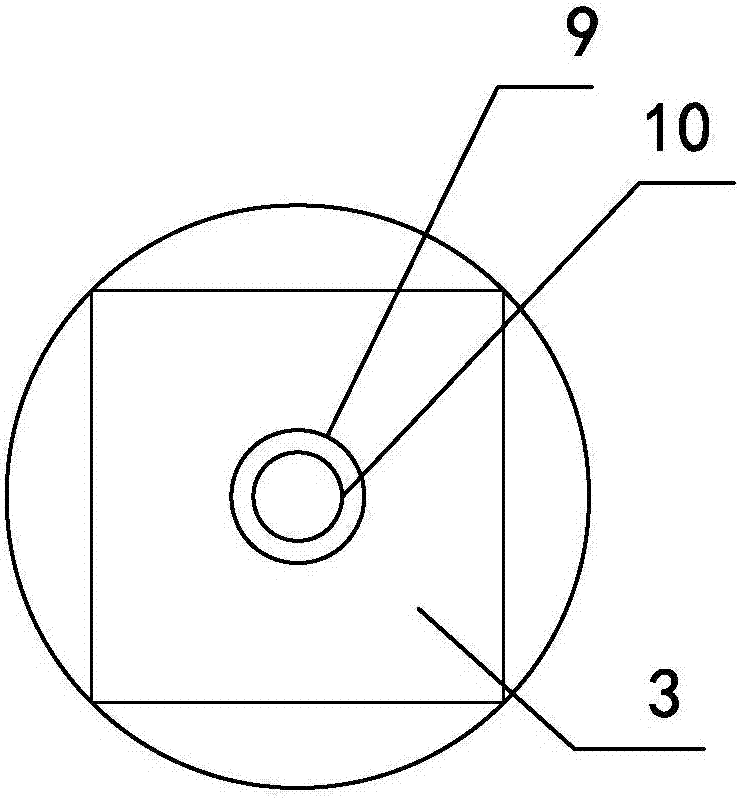

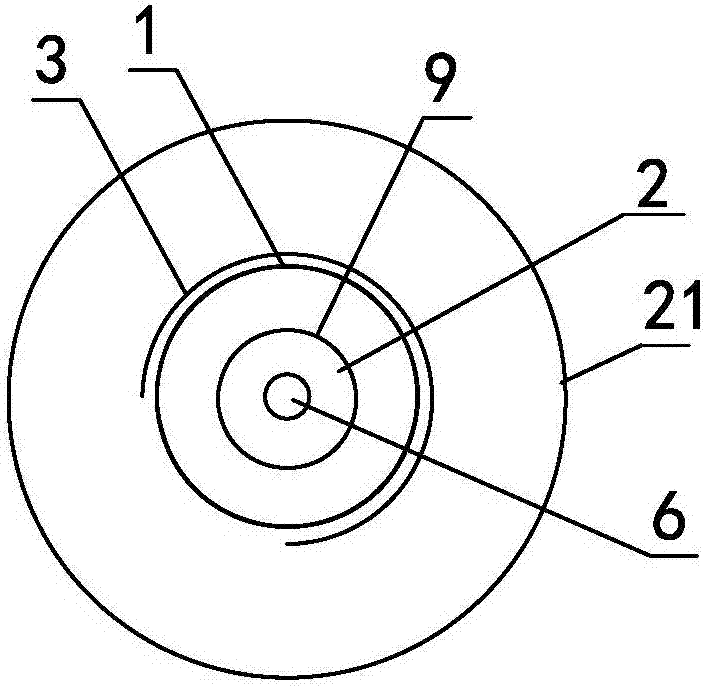

[0078] Such as Figure 1 to Figure 7 As shown, the wire 6 of this embodiment is a CFRP stranded wire with a diameter of 12mm composed of 7 carbon fiber bundles. The anchorage structural device includes an integrated clip structure 1, a soft metal sheath 2, and an external Anchor ring 3 with thread and lock nut 21, rear jacking part 4 and anchor plate 5, wherein anchor plate 5 is a spherical anchor plate, and rear jacking part 4 is a bolt.

[0079] The middle part of the anchor ring 3 is provided with an inner tapered hole 8 extending along its center line. The inner tapered hole 8 is provided with an integrated clip structure 1 matching its shape. The axial length L of the integrated clip structure 1 is less than or equal to the anchor ring. The axial length W of the ring 3 . The one-piece clip structure 1 is made of stainless steel and integrally spliced by a short cylinder 13 and a slender round platform, and the outer envelope line of its longitudinal section is an obliq...

Embodiment 2

[0094] Such as Figure 9 As shown, the difference between this embodiment and the first embodiment is that the wire 6 is an embossed BFRP tendon of basalt fiber reinforced composite material, the anchor plate 5 is a plane anchor plate, and the left end of the anchor ring 3 is in plane contact with the plane anchor plate. The included angle θ is 3°, and the included angle α is 2.9°. The axial length L of the one-piece clip structure 1 is greater than the axial length W of the anchor ring 3 , and when in use, the front end of the one-piece clip structure 1 can extend out of the anchor ring 3 to the left.

[0095] The cross-section of the soft metal sheath 2 is two semicircular rings buckled together, which are made of copper foil with a thickness of 0.8mm. The inner walls of the two semicircular soft metal sheaths 2 are sealed with epoxy resin glue. Paste 120-mesh quartz sand to form a protective layer that increases friction. The BFRP tendon in the anchoring area wraps the so...

Embodiment 3

[0098] Such as Figure 10 , Figure 11 As shown, this embodiment is an AFRP bar full-length bonded rock bolt applied to rock slope anchoring engineering, that is, a tension-type full-length bonded rock bolt. The anchoring structure is a rocky slope. The difference between this embodiment and the second embodiment is that the device wire 6 of the present invention is an embossed AFRP bar of a single aramid fiber reinforced composite material with a length of 21 m and a diameter of 20 mm, and the rear jacking part 4 is an anti-corrosion nut cap. The axial length L of the one-piece clip structure 1 is less than or equal to the axial length W of the anchor ring 3 , and the one-piece clip structure 1 is placed inside the anchor ring 3 during use.

[0099] The principle of the assembly method in Embodiment 1 is the same, the construction steps of the AFRP tendon tensile type full-length bonded rock bolt assembly method in this embodiment are as follows:

[0100] a. Drill a rock a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com