Integrated supercapacitor and manufacturing method thereof

A supercapacitor and gel electrolyte technology, applied in the field of energy storage, can solve the problems of poor performance of electrode materials, difficult to degrade and recycle electrode sheets, complex assembly process, etc., and achieve the effects of improved performance, environmental friendliness, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

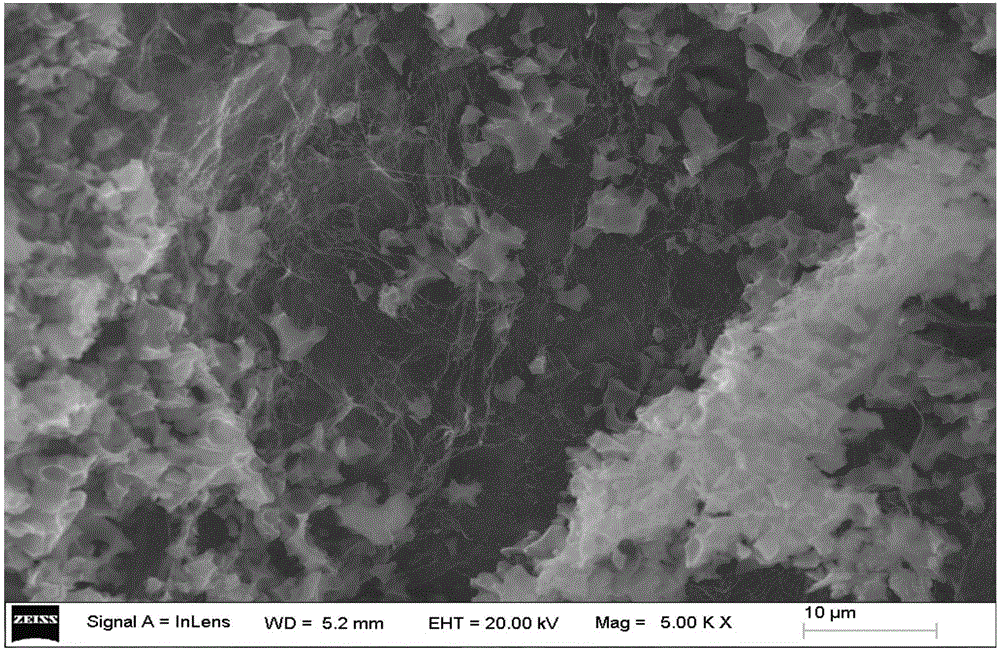

[0022] (1) Take by weighing 27g of bacterial cellulose blocks stored in glacial acetic acid, first wash to neutral with deionized water, then mix the cleaned bacterial cellulose with 540ml of deionized water, at a speed of 9000r / min, Mechanical pulverization for 15 minutes to obtain a uniform slurry suspension;

[0023] (2) Pour the bacterial cellulose slurry prepared in step (1) into a container, add acetone and stir evenly, seal the container and place it in a refrigerator fresh-keeping cabinet, and store it for 1 to 3 days, and control the acetone and deionized water The volume ratio is 1:1;

[0024] (3) Put the bacterial cellulose slurry prepared in step (2) into a cell pulverizer, and ultrasonicate at a power of 50W for 10 minutes; then suction filter to form a film, and wash with acetone and deionized water respectively once during the suction filtration process ;Then the membrane was stirred and dispersed in deionized water again to form a homogeneous slurry, wherein t...

Embodiment 2

[0028] (1) Take by weighing 47g of the bacterial cellulose block stored in glacial acetic acid, wash it to neutrality with deionized water, then mix the cleaned bacterial cellulose with 470ml of deionized water, at a speed of 12000r / min, Mechanical pulverization for 10 minutes to obtain a uniform slurry suspension;

[0029] (2) Pour the bacterial cellulose slurry prepared in step (1) into a container, add acetone and stir evenly, seal the container and place it in a refrigerator fresh-keeping cabinet, and store it for 1 to 3 days, and control the acetone and deionized water The volume ratio is 1:3;

[0030] (3) Put the bacterial cellulose slurry prepared in step (2) into a cell pulverizer, and ultrasonicate for 6 minutes at a power of 100W; then suction filter to form a film, and wash twice with acetone and deionized water respectively during the suction filtration process ;Then the membrane is stirred and dispersed in deionized water again to form a homogeneous slurry, where...

Embodiment 3

[0034](1) Take by weighing 64g of bacterial cellulose block stored in glacial acetic acid, first wash it to neutral with deionized water, then mix the cleaned bacterial cellulose with 320ml of deionized water, at a speed of 18000r / min, Mechanical pulverization for 5 minutes to obtain a uniform slurry suspension;

[0035] (2) Pour the bacterial cellulose slurry prepared in step (1) into a container, add acetone and stir evenly, seal the container and place it in a refrigerator fresh-keeping cabinet, and store it for 1 to 3 days, and control the acetone and deionized water The volume ratio is 1:5;

[0036] (3) Put the bacterial cellulose slurry prepared in step (2) into a cell pulverizer, and ultrasonicate for 3 minutes at a power of 150W; then suction filter to form a membrane, and wash twice with acetone and deionized water respectively during the suction filtration process ;Then the membrane is stirred and dispersed in deionized water again to form a homogeneous slurry, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com