A kind of preparation method of silicon-based catalytic cracking catalyst

A catalytic cracking and catalyst technology, applied in the field of preparation of silicon-based catalytic cracking catalysts, can solve the problems of easy gelation of colloids, easy loss of fluidity, poor stability of acid silica sols and difficult storage, etc. Beneficial for rapid diffusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

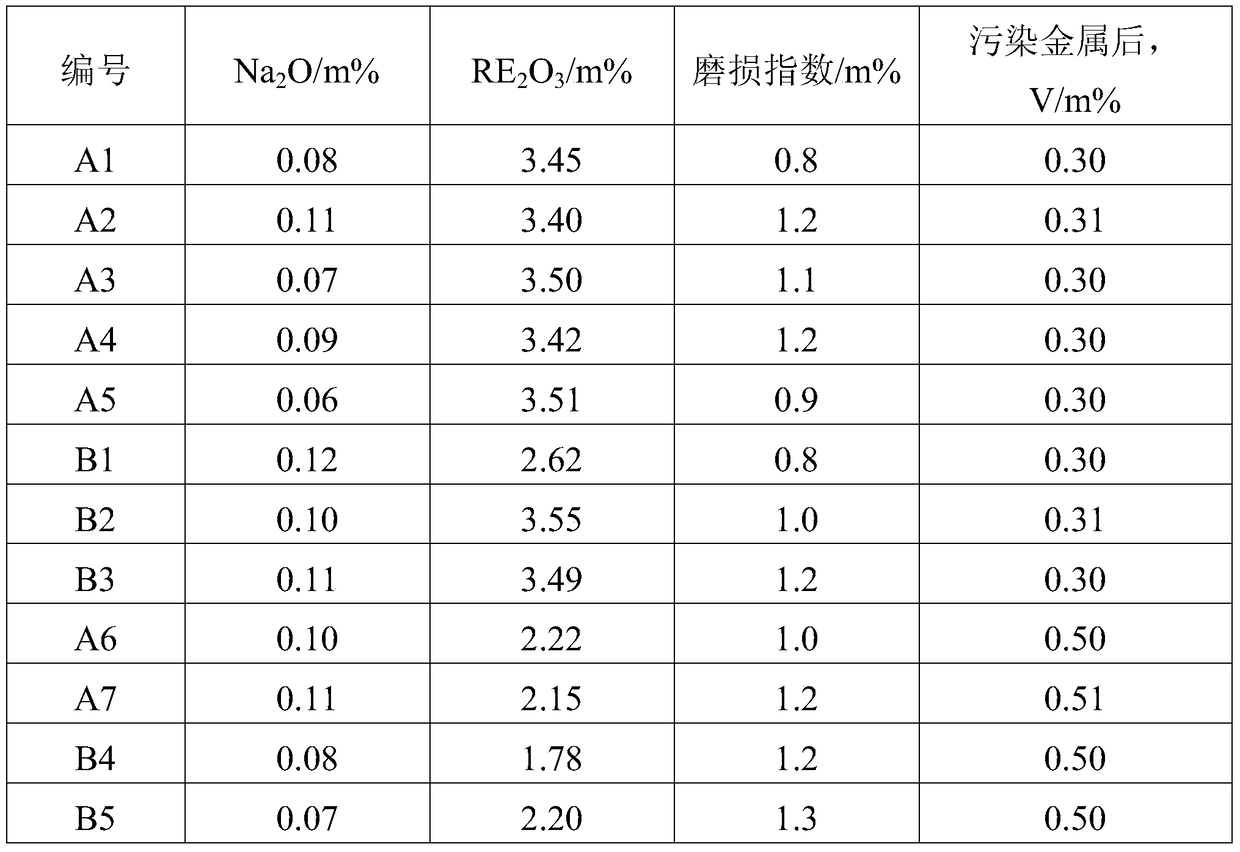

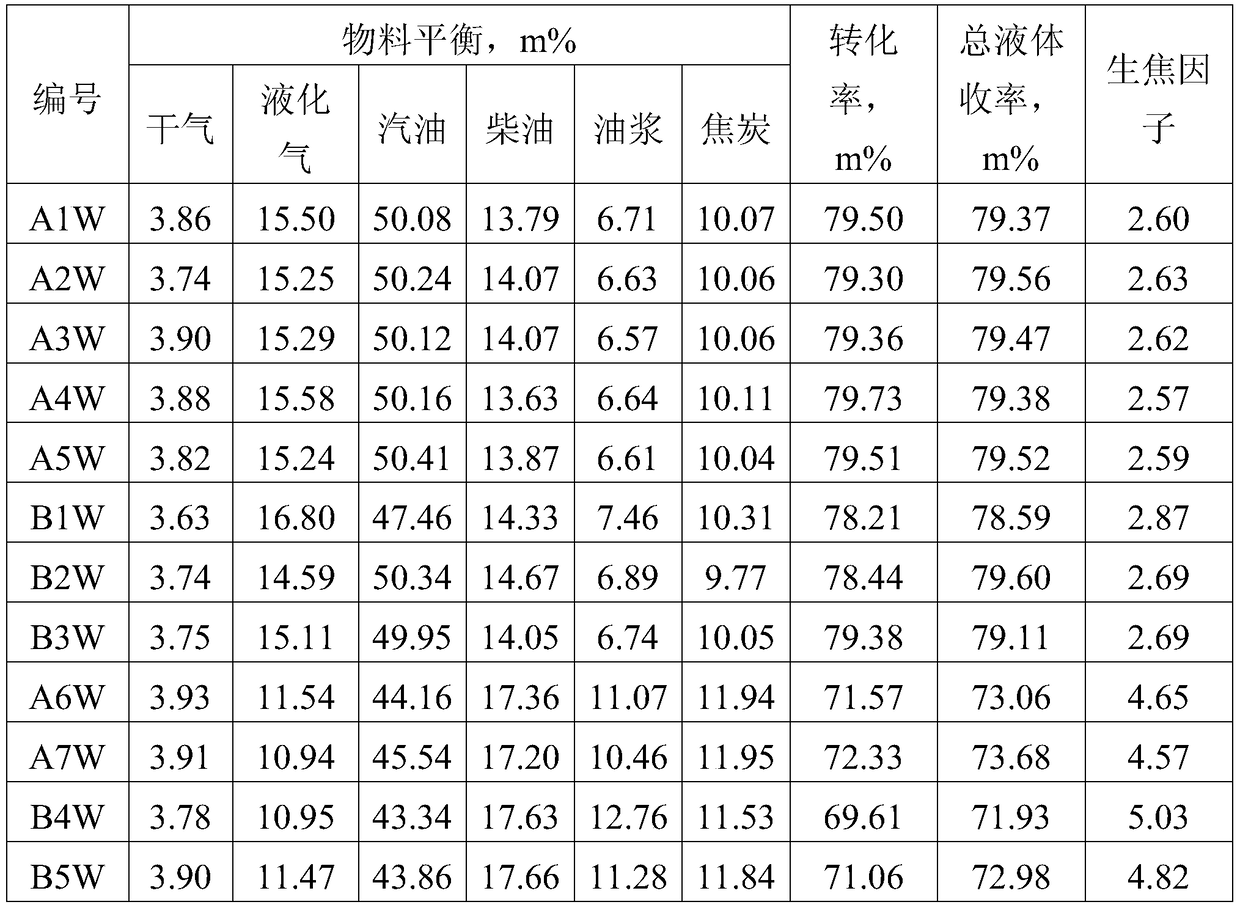

Examples

Embodiment 1

[0045] In the reaction tank with water bath heating, add 2.3kg water, 857g aluminum sol (solid content 21% by weight), add 909g activated alumina (solid content 66% by weight) under stirring, then slowly add hydrochloric acid and carry out peptization, Stir for 1h. The initial pH value of sodium-type alkaline silica sol (30% by weight of silicon dioxide content) is 9.60. Weigh 1000 g of alkaline silica sol, add 9 ml of concentrated hydrochloric acid (concentration 37% by mass) under stirring conditions, and stir evenly to obtain the pH value 3.0 hydrochloric acid modified alkaline silica sol; 1.28kg of REHY molecular sieve with a solid content of 82% by weight plus 1.92kg of water for beating and dispersion, adding 3% oxalic acid relative to the dry basis of the molecular sieve and relative to the dry basis of the catalyst RE 2 o 3 A 1.0% rare earth aqueous solution by mass, in which oxalic acid is pre-dissolved in water, is stirred for 40 minutes respectively to obtain a mo...

Embodiment 2

[0047] In a reaction tank with water bath heating, add 2.3kg of water, add 909g of activated alumina (solid content 66% by weight) under stirring, then slowly add hydrochloric acid for peptization, stir for 1h, add 786g aluminum sol (solid content 21% by weight) weight%). The initial pH value of sodium-type alkaline silica sol (silicon dioxide content 30% by weight) is 9.60. Weigh 1000 g of alkaline silica sol, add 8 ml of concentrated hydrochloric acid (concentration 37 mass %) under stirring conditions, and stir evenly to obtain the pH value 3.5 hydrochloric acid modified alkaline silica sol; 1.28kg of REHY molecular sieve with a solid content of 82% by weight plus 1.92kg of water for beating and dispersion, adding 3% oxalic acid relative to the dry basis of the molecular sieve and relative to the dry basis of the catalyst RE 2 o 3 A 1.0% rare earth aqueous solution by mass, in which oxalic acid is pre-dissolved in water, is stirred for 40 minutes respectively to obtain a ...

Embodiment 3

[0049] In a reaction tank with water bath heating, add 2.3kg of water, add 864g of activated alumina (solid content: 66% by weight) under stirring, then slowly add hydrochloric acid for peptization, and stir for 1 hour. The initial pH value of sodium-type alkaline silica sol (silica content 30% by weight) is 9.60. Weigh 1000 g of alkaline silica sol, add 7 ml of concentrated hydrochloric acid (concentration 37 mass %) under stirring conditions, and stir evenly to obtain the pH value 3.8 hydrochloric acid modified alkaline silica sol; 1.28kg of REHY molecular sieves with a solid content of 82% by weight plus 1.92kg of water for beating and dispersion, adding 3% oxalic acid relative to the dry basis of the molecular sieve and relative to the dry basis of the catalyst RE 2 o 3 A 1.0% rare earth aqueous solution by mass, in which oxalic acid is pre-dissolved in an appropriate amount of water, and stirred for 40 minutes respectively to obtain a modified molecular sieve slurry. Ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com