Clean chemical work station

A workstation and chemical technology, applied in the field of microelectronic process equipment, can solve the problems of less safety and reliability of the purification workbench, gas leakage, etc., and achieve the effects of improving the orderliness of the air flow, preventing the air flow from rebounding, and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

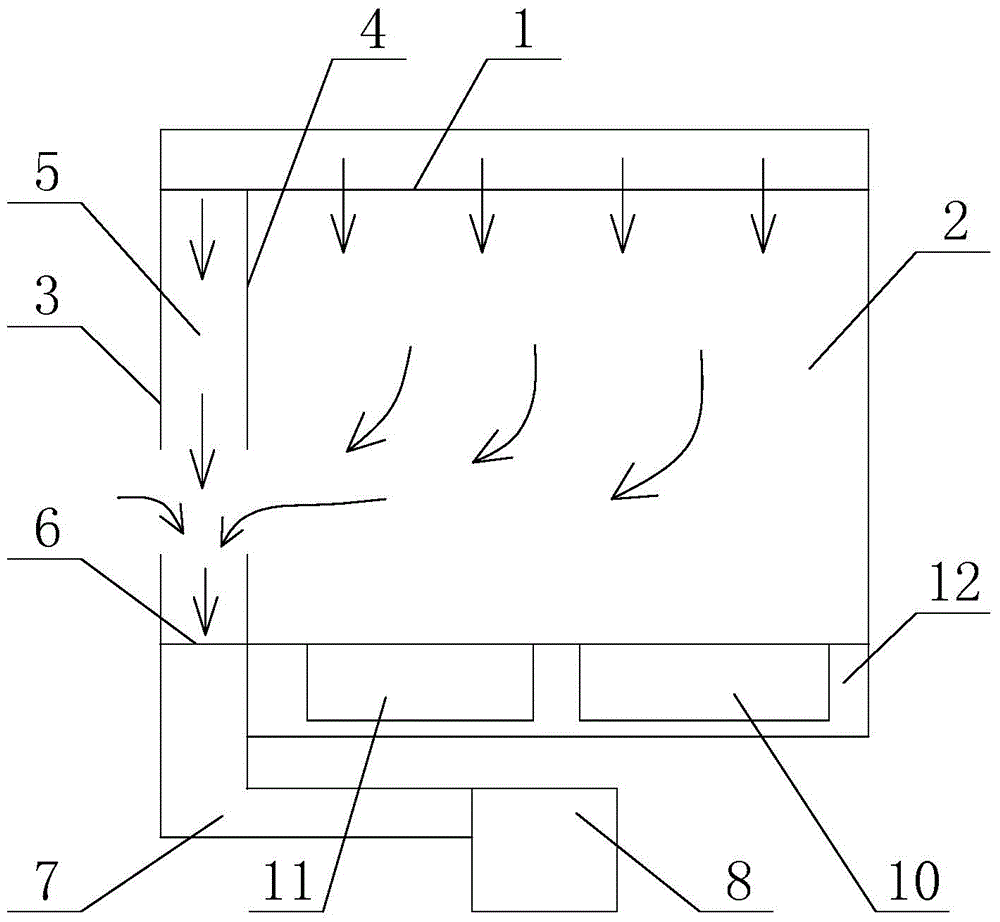

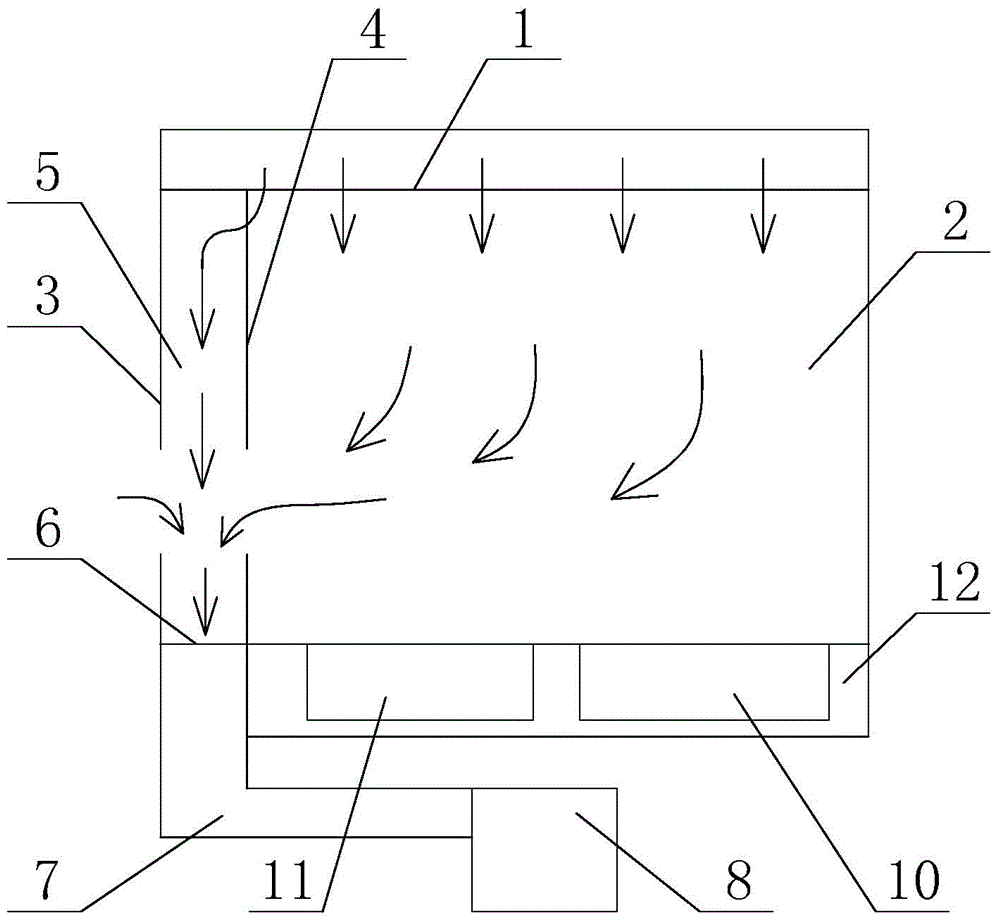

[0028] Such as figure 1 As shown, the present embodiment purifies the chemical workstation, the purification workbench and the water bath heating pool 10 and the cleaning water pool 11 placed inside the purification workbench. Among them, the purification workbench includes an air intake system and an exhaust system. A diffuser plate 1 is provided below the air intake system. A working cavity 2 is located below the diffuser plate 1. A base 12 is provided below the working cavity 2. A water bath heating pool 10 and The cleaning pool 11 is embedded in the base. There is a transparent end plate 2 with an operation hole 9 near the outer end of the working cavity 2 of the staff (see Figure 4 ), the side of the working cavity 2 close to the end plate 3 is a transparent partition 4, and the transparent partition 4 has an operation hole for the staff to extend their hands into the interior of the working cavity for operation (the structure of the partition 4 can be compared with the...

Embodiment 2

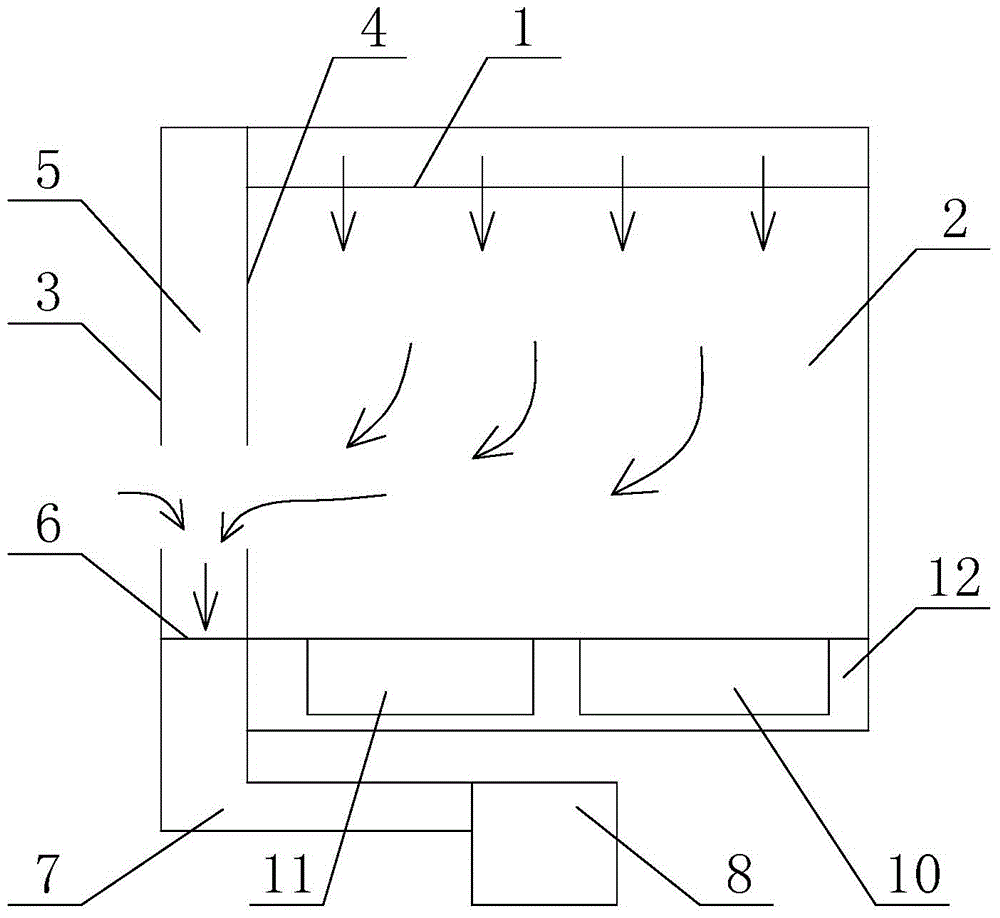

[0034] Such as image 3As mentioned above, the purification chemical workstation in this embodiment is a simplified solution of the purification chemical workstation in Embodiment 1, the specific difference is that no purified air is introduced above the partition of the purification workbench. Specifically, the purification chemical workstation in this embodiment includes a purification workbench and a water bath heating pool 10 and a cleaning water pool 11 placed inside the purification workbench. The purification workbench includes an air intake system and an exhaust system. A diffuser plate 1 is provided below the air intake system. A working chamber 2 is located below the diffuser plate 1 and a base 12 is located below the working chamber. The outer end of the working cavity 2 close to the staff has a transparent end plate 2 with an operation hole 9, and the side of the working cavity 2 close to the end plate 3 is a transparent partition 4, and the transparent partition 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com