Unidirectional moisture conducting shell fabric

A unidirectional moisture-wicking and fabric technology, which is applied in the direction of decorative textiles, textiles and papermaking, weft knitting, etc., can solve the problems of low product quality stability, increased printing process, complex production process, etc., and achieve good economic benefits. Good effect on improving comfort index, physical and chemical indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

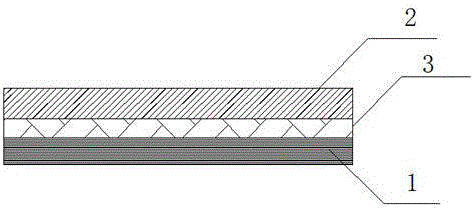

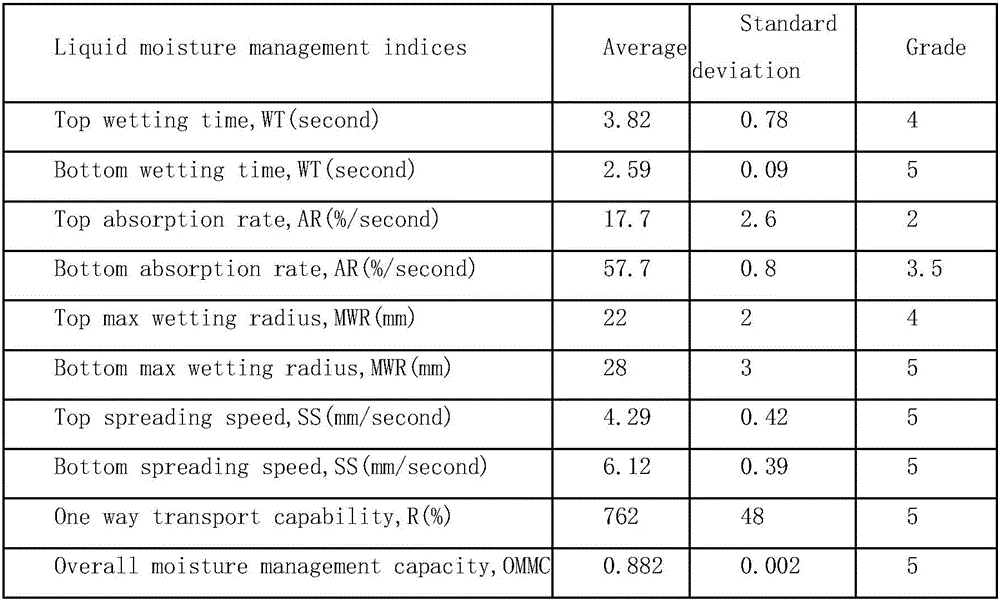

[0013] Such as figure 1 As shown, a unidirectional moisture-wicking fabric is characterized in that, a double-sided fabric is formed by weaving polypropylene and modified polyester through a double-sided machine, the polypropylene is 50D polypropylene, and the modified polyester is 75D polyester. The 50D polypropylene fiber fineness is 55dtex, and the 75D polyester fiber fineness is 83.3dtex, wherein the inner layer of polypropylene forms a hydrophobic surface 1 for direct contact with the skin, the modified polyester forms a hydrophilic surface 2 on the outer layer, polypropylene and The modified polyester is interwoven in the middle to form the middle interweaving layer 3, the mass fraction of the total mass of the polypropylene fiber is 45%, the mass fraction of the total mass of the modified polyester is 55%, and the polypropylene fiber is a modified polypropylene fiber. The dyeing of the above-mentioned modified polypropylene fiber adopts stock solution coloring, that is,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com