Fuel valve for injecting fuel into the combustion chamber of an internal combustion engine

A technology for fuel valves and internal combustion engines, which can be used in fuel injection devices, fuel injection control, liquid fuel engines, etc., and can solve problems such as crowded roof spaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] specific implementation plan

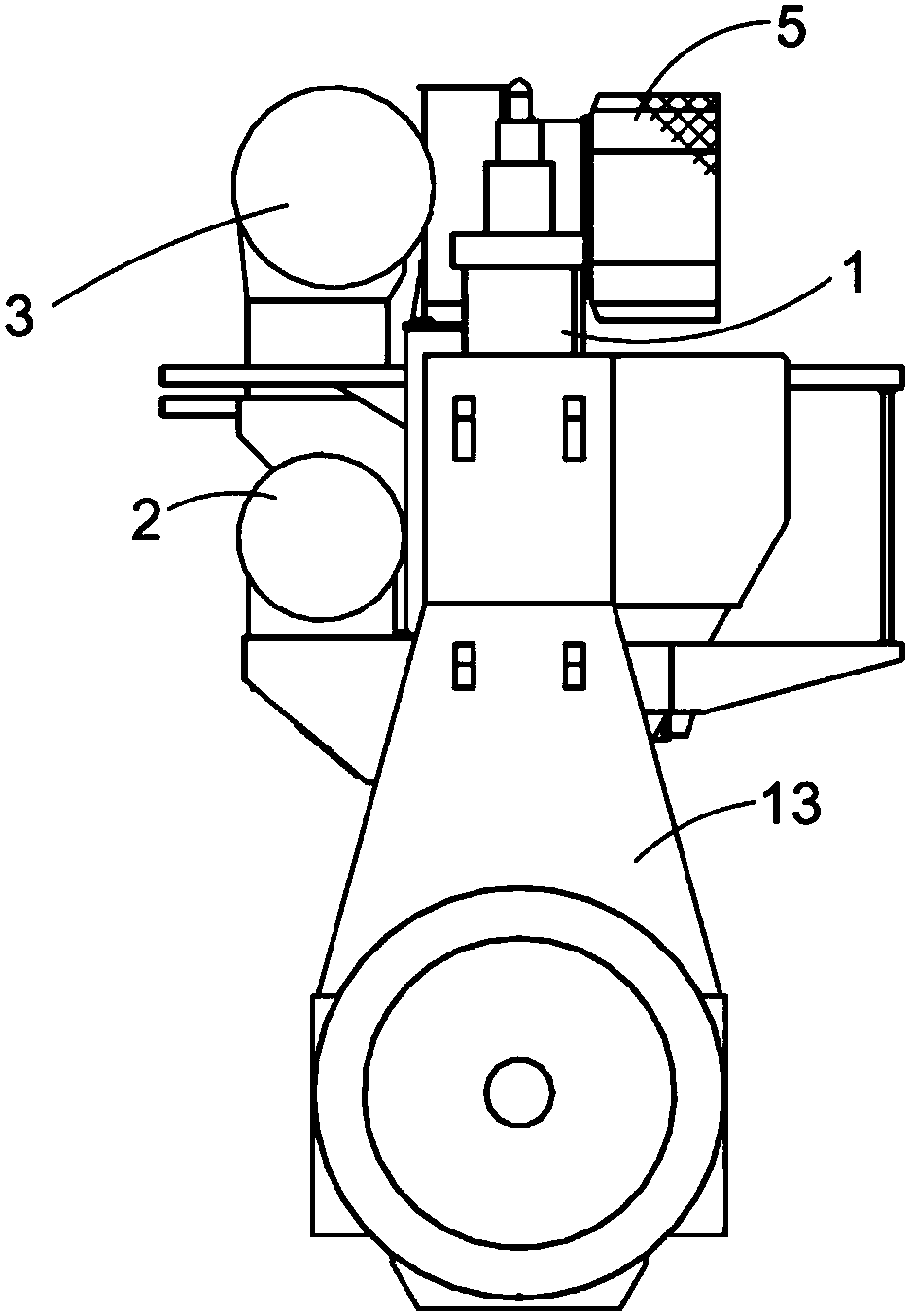

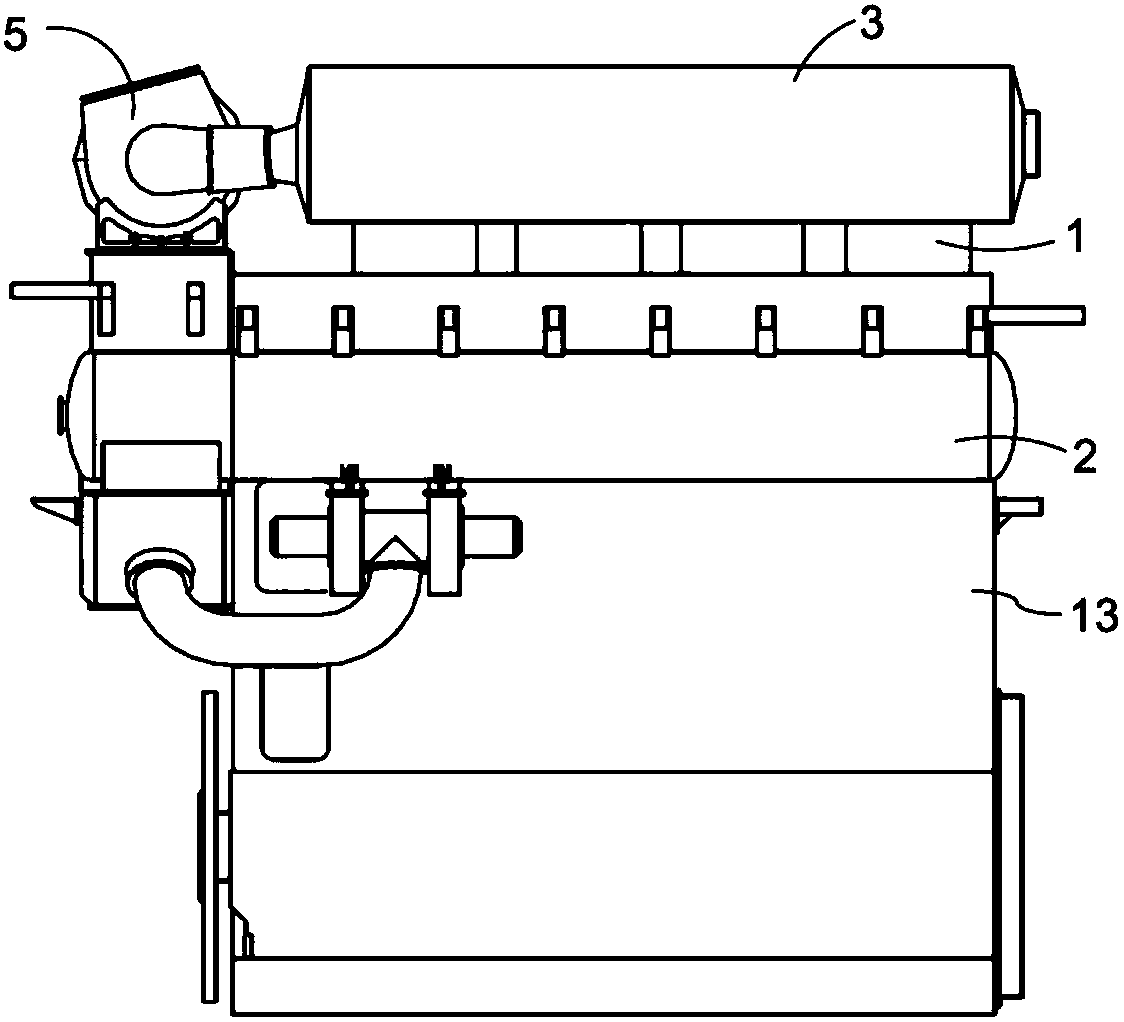

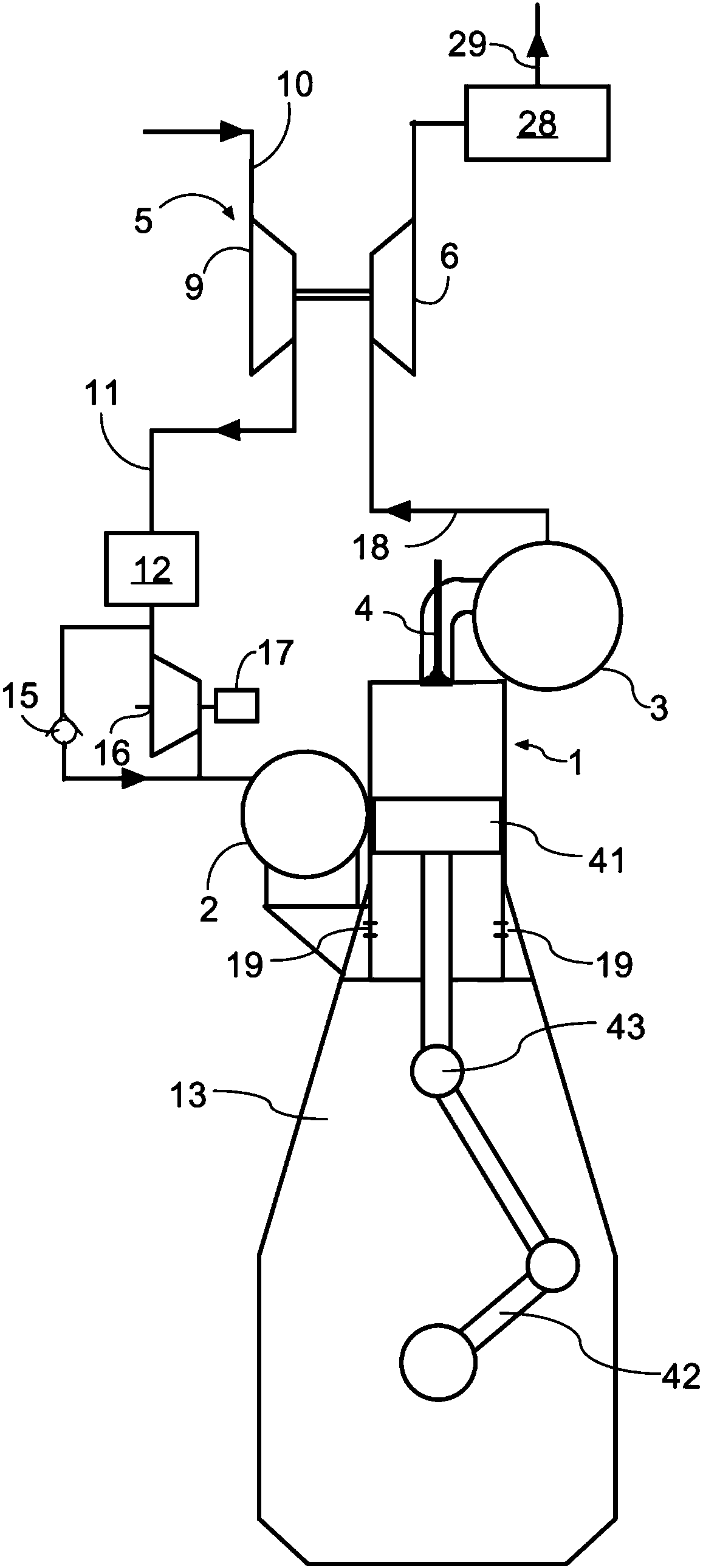

[0038] In the following detailed description, a self-ignition internal combustion engine will be described with reference to a large two-stroke low-speed turbocharged internal combustion (diesel) engine in an exemplary embodiment.figure 1 , 2 and 3 show a large low-speed turbocharged two-stroke diesel engine with crankshaft 42 and crosshead 43 . image 3 Schematic showing a large low-speed turbocharged two-stroke diesel engine with its intake and exhaust systems. In this exemplary embodiment, the engine has four cylinders 1 in-line. Large low-speed turbocharged two-stroke diesel engines typically have between 4 and 14 cylinders in-line and are carried by the engine frame 13 . The engine can be used, for example, as the main engine of an ocean-going vessel or as a stationary engine for operating a generator of a power station. The overall output of the engine may, for example, be in the range of 1,000-110,000 kW.

[0039] The engine in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com