Manufacturing method of display device and color filter thereof

A color filter and display device technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of expensive half-tone masks and achieve the effects of maintaining uniformity, increasing margins, and reducing air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

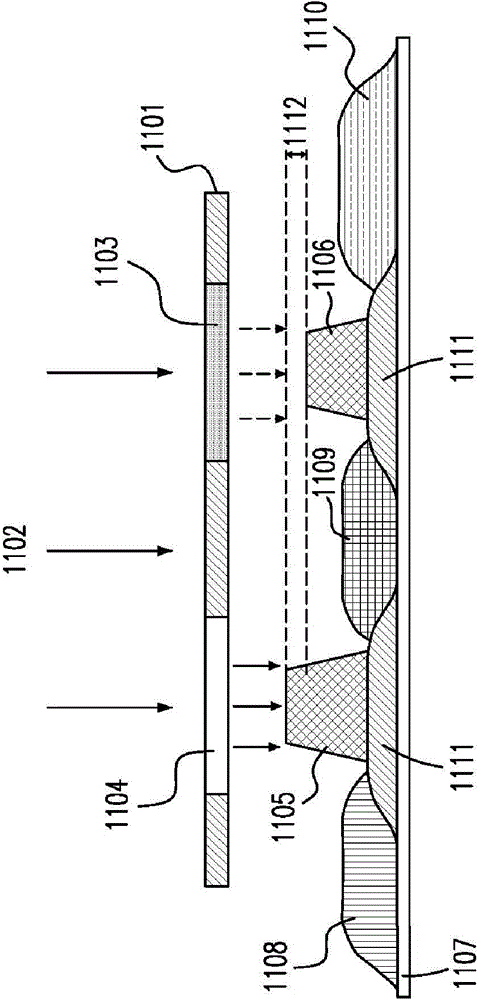

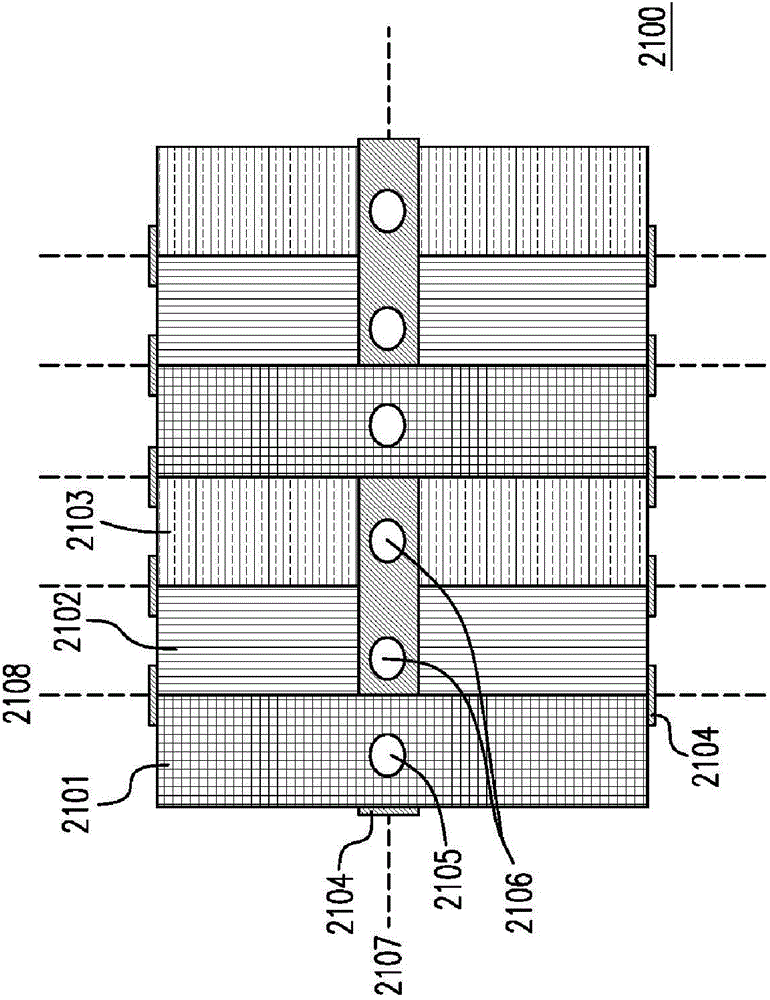

[0018] A schematic diagram of a preferred embodiment of the display device provided by the present invention is as follows Figure 2(a) ~ Figure 2(d) As shown, firstly, the color filter 2100 shown in FIG. Compared with the strip-shaped filter layer pattern 2101, the middle part of the island-shaped filter layer pattern (2102, 2103) is truncated and discontinuous and not interlaced with the light-shielding layer pattern 2104, that is, two islands A light-shielding layer pattern 2104 is interposed between the strip-shaped filter layer patterns (2102, 2103), wherein the strip-shaped filter layer pattern 2101 takes a green filter layer as an example, and the two island-shaped filter layer patterns (2102, 2103) are respectively colored in red Take the filter layer and the blue filter layer as an example, they are arranged circularly in the order of the colors selected above, however, any of the above filter layer patterns can be red filter layer, green filter layer, blue filter lay...

Embodiment 2

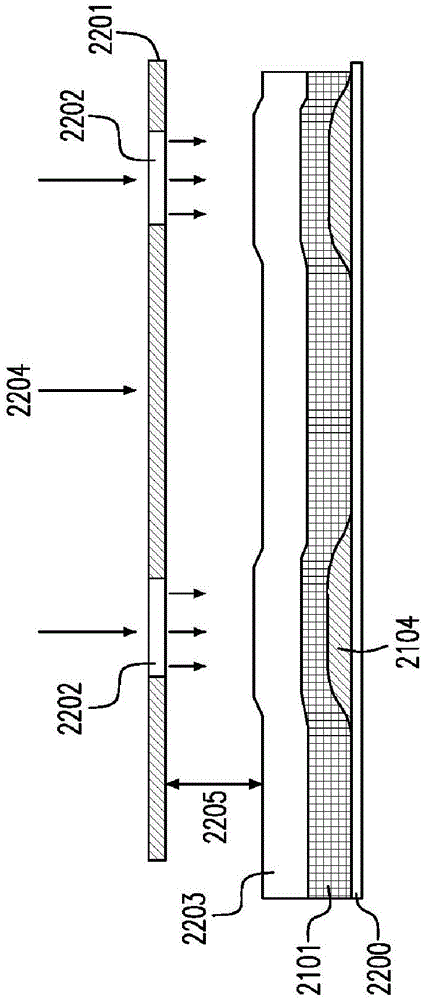

[0023] A schematic diagram of a preferred embodiment of the liquid crystal display device provided by the present invention is as Figure 3(a) ~ Figure 3(b) As shown, firstly, the color filter 3100 shown in FIG. The definition is the same as the previous embodiment, wherein the strip filter layer pattern 3101 takes the green filter layer as an example, and the two island-shaped filter layer patterns (3102, 3103) take the red filter layer and the blue filter layer as examples respectively. , arranged circularly in the order of the selected colors above, however, the pattern of the above-mentioned filter layer can be one of the red filter layer, green filter layer, blue filter layer and white filter layer, wherein the pattern of the filter layer below The light-shielding layer pattern 3104 is set, and the light-shielding layer pattern is a pattern of horizontal and vertical strips, and its function is the same as that of the previous embodiment, and the strip-shaped filter layer...

Embodiment 3

[0026] A display device, comprising: a first substrate; a plurality of filter layer patterns are arranged on the first substrate, wherein a light-shielding layer pattern is arranged under two adjacent filter layer patterns; wherein the filter layer patterns include strips Shaped filter layer pattern and island-shaped filter layer pattern; The second substrate is arranged opposite to the first substrate; and the first spacer has a first end and a second end, and the first end is in contact with the On the second substrate, the second end is in contact with the striped filter layer pattern.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com