Permanent magnet electric device, an electric car and driving, brake and range increasing method thereof

A technology for electric devices and electric vehicles, which is applied in the deceleration devices of DC motors, electromechanical devices, electric vehicles, etc., can solve the problems of short continuation mileage, unrealistic continuation mileage, and high manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

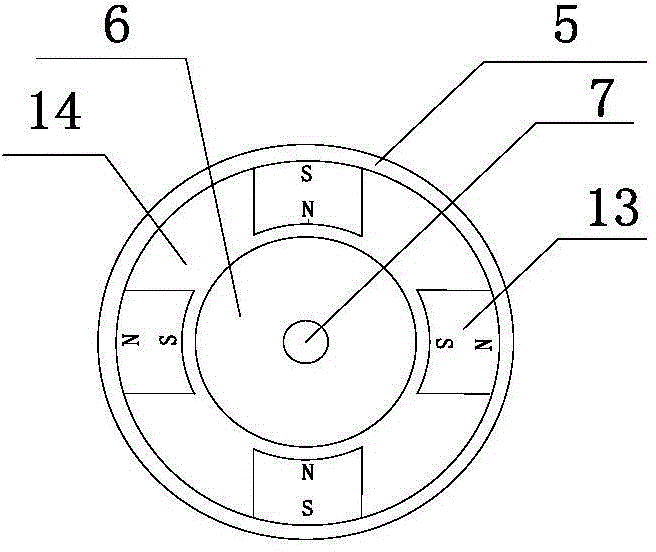

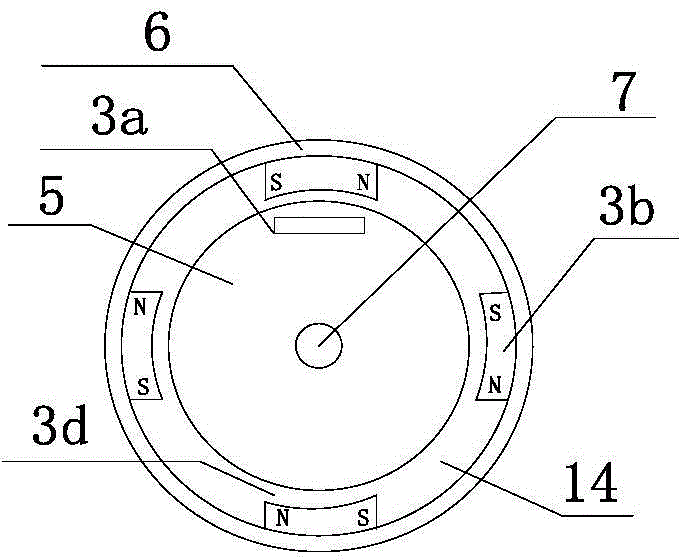

[0094] An electric device and its matching electric two-wheeled vehicle, the motor body of the electric device is arranged on the rear wheel, and its local structure on the vehicle frame 4 is as follows: Figure 10a As shown, the circumference of the wheel is 1000mm, and the battery pack 8 is a 24V12Ah lithium iron phosphate battery installed inside the frame. The fixed body 5 of the electric device is designed as a disk with a fixed shaft outside, and the external mechanical parameters of the fixed shaft are designed with reference to the data of the conventional two-wheeled wheel axle, and are used to replace the conventional two-wheeled wheel shaft for installation; the rotating body 6 of the electric device utilizes A double-annular titanium-aluminum alloy ring with a rotating shaft and an inner circumference of 500 mm (generally referred to as a hub in industry practice), which can be coaxially fitted with the fixed body on the outside of the fixed body of the disc; when t...

Embodiment 2

[0102] The electric device described in embodiment 1 is configured on the front wheel of a tricycle, and the local structure of the vehicle frame 4 is as follows: Figure 10b Shown; The design installation method of the circumference of wheel and swivel, stator unit and rotor unit is similar to embodiment 1, and battery pack 8 selects 48V100Ah lead-acid colloid battery for use, is installed in the battery box inside vehicle frame.

[0103] The outside of the rotating body 6 is provided with a deceleration / torque conversion device 2 composed of several gears, which is installed concentrically with the rotating body, such as Figure 10b As shown in the front wheel of a tricycle, the reduction ratio of the deceleration / torque conversion device is 10:1; the transmission input end of the deceleration / torque conversion device is fixedly connected with the rotating body, and there are several mechanical holes on the outside, and one end of several spokes is perforated and fixed , the...

Embodiment 3

[0109] An electromagnetic braking function is added to the electric device described in Embodiment 1.

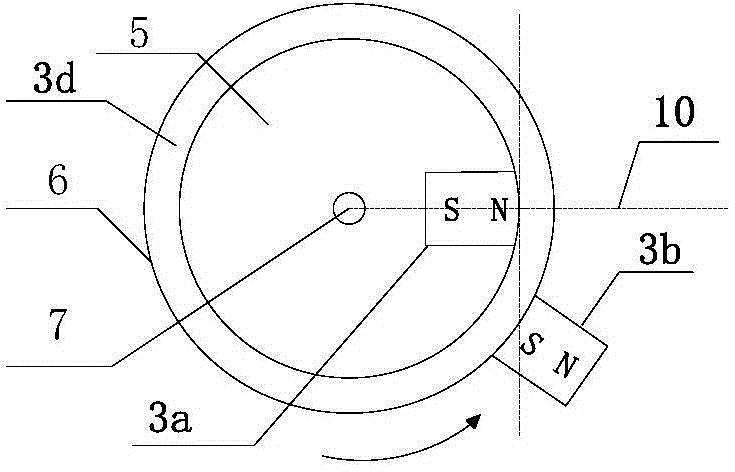

[0110] The electromagnetic braking device 9b is a ten-stage rheostat, and the power supply modulator correspondingly adds a braking signal input terminal 1e to electrically connect the electromagnetic braking device 9b, such as Figure 5c Shown; when the manual control electromagnetic brake device sends a braking signal, the power modulator cuts off T 1 corresponding to the timing current, start T 2 The time domain is energized, and the brake energization time domain is set so that the sensing unit 3c senses the rotor unit 3b around the shaft to 4 degrees to The time period for the 0 position.

[0111] The brake current output by the power modulator corresponds to the ten-level resistance of the electromagnetic braking device 9b, which is set to ten-level intensity, and the output current intensity is set to be: the first level is 5A, the last level is 12A, and the ten-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com