Intelligent differential pressure alarming filter device

A filter and intelligent technology, applied in the direction of filtration and separation, chemical instruments and methods, separation methods, etc., can solve the problems affecting the wellhead back pressure and production of oil wells, high work intensity, and inadequate supervision, etc., so as to reduce the labor intensity of employees, Improve the degree of automation and the effect of simple construction technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

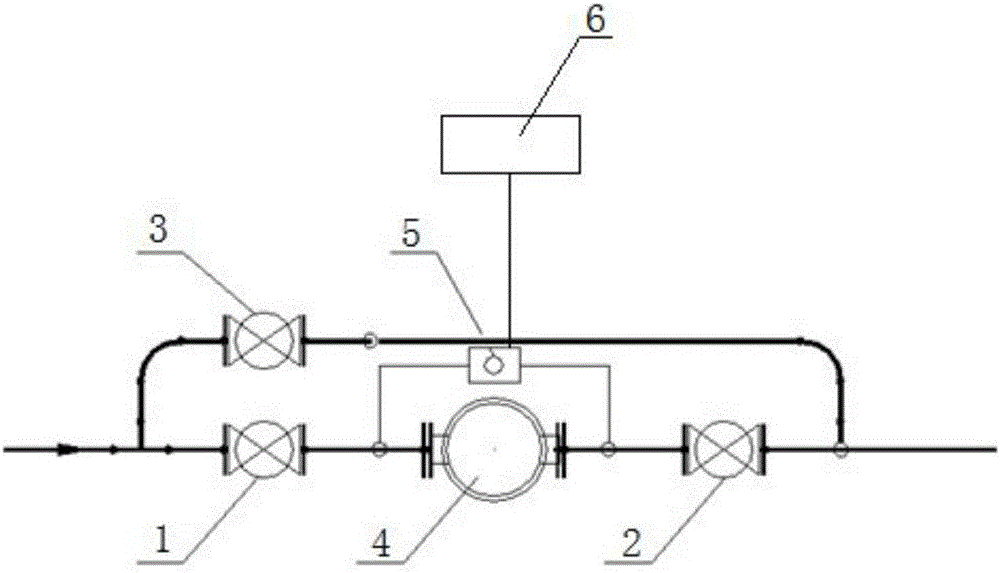

[0027] Such as figure 1 As shown, an intelligent differential pressure alarm filter device includes a filter 4, which is characterized in that it also includes an inlet control valve 1, an outlet control valve 2, a bypass control valve 3, and a pressure monitoring instrument 5. The inlet of the filter 4 is connected to one end of the inlet control valve 1 through a pipe, the outlet of the filter 4 is connected to one end of the outlet control valve 2 through a pipe, and the other ends of the inlet control valve 1 and the outlet control valve 2 are respectively connected to the bypass control through a pipe At both ends of the valve 3, the pressure monitoring instrument 5 is connected in parallel with the filter 4, and the pressure monitoring instrument 5 is electrically connected to the station control system 6. .

[0028] The present invention monitors the differential pressure value ΔP at the inlet and outlet of the filter 4 through the pressure monitoring instrument 5, conver...

Embodiment 2

[0038] On the basis of Example 1, the filter 4 is a blue filter for pipelines. The basket filter is a small device that removes a small amount of solid particles in the liquid. When the fluid enters the filter cartridge with a certain filter screen, its impurities are blocked, and the clean filtrate is discharged from the filter outlet. When cleaning is required, As long as the detachable filter cartridge is taken out and reinstalled after treatment, it is extremely convenient to use and maintain. A filter screen is set in the filter 4 to remove impurities and dirt carried in the conveying fluid.

Embodiment 3

[0040] On the basis of embodiment 1, the pipes connecting the inlet control valve 1, the outlet control valve 2 and the bypass control valve 3 are steel pipes, and the inlet control valve 1, the outlet control valve 2 and the bypass control valve Valve 3 is a manual steel wedge gate valve. The steel wedge gate valve has the advantages of small flow resistance, small opening and closing torque, short structure length, and unlimited medium flow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com