Mesoporous organosilica hollow nanoparticles with asymmetric morphology and synthetic method of mesoporous organosilica hollow nanoparticles

A mesoporous organosilicon, hollow nanotechnology, applied in the field of mesoporous nanomaterials, can solve the problems of limited application, difficult control of composition and particle size, etc., and achieve the effect of fast adsorption rate, high adsorption capacity, and enhanced ultrasonic signal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] 1) use Core SiO prepared by ber method 2 nanoparticles;

[0037] 2) Using double silicon-based organoalkoxysilane as silicon source and cationic surfactant as pore-forming agent, in the SiO 2 Nanoparticles coated with a layer of SiO hybridized with organic functional groups 2 Layer, the specific process is:

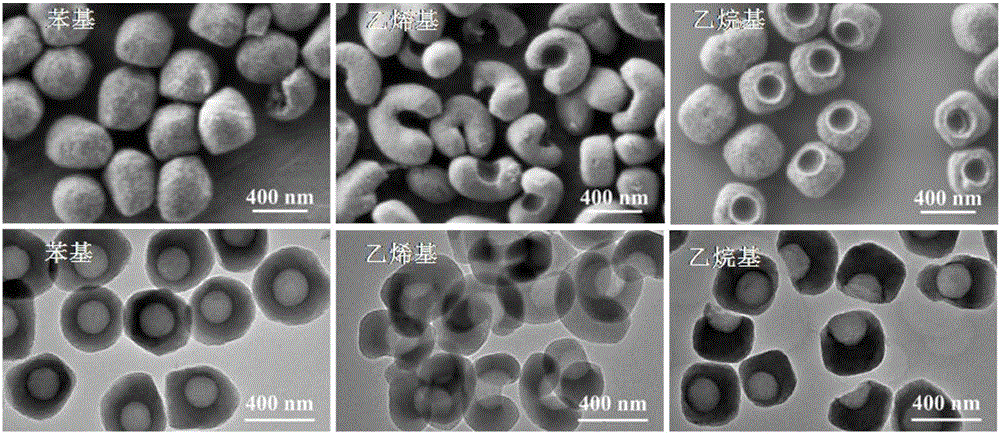

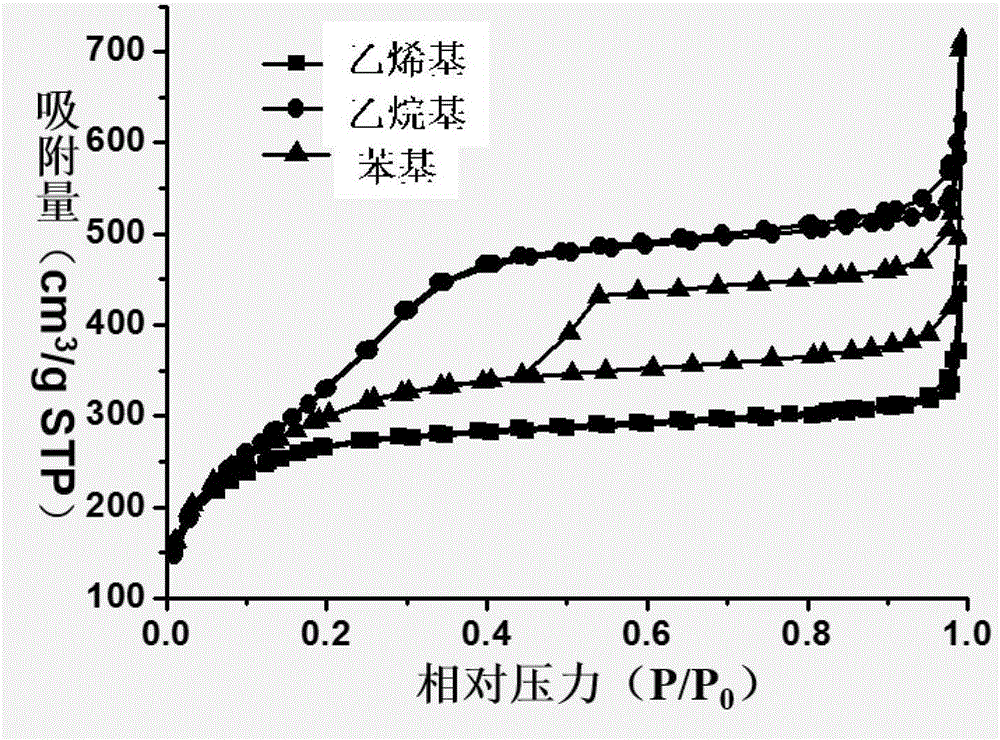

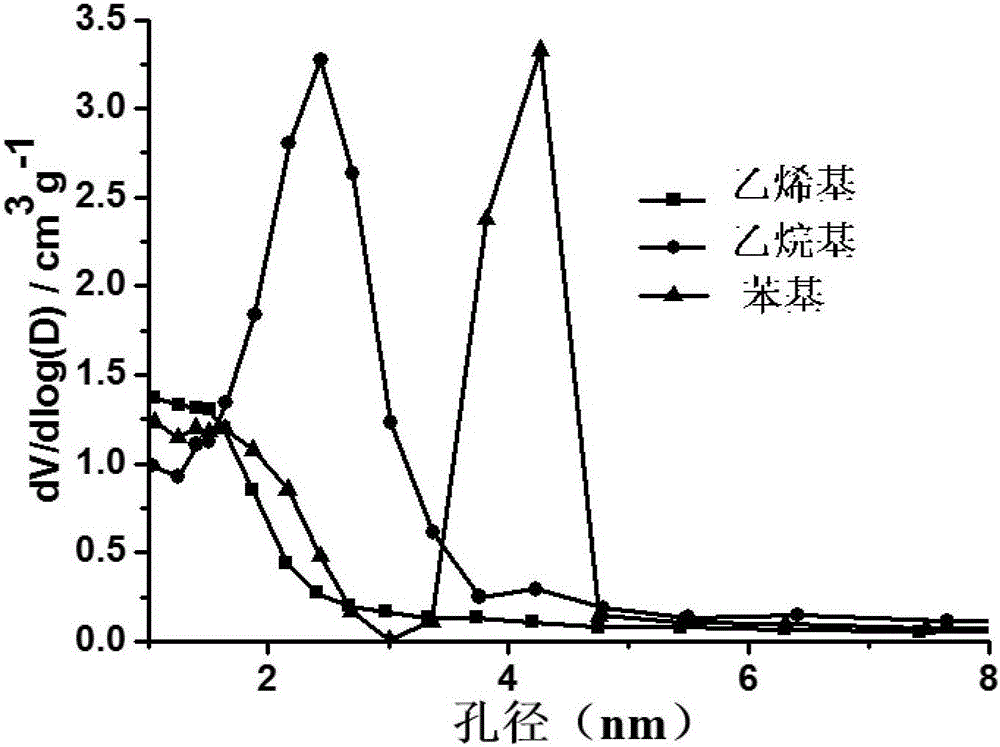

[0038] The 100mg core SiO 2 Nanoparticles dispersed into 2.5mL ethanol to form a suspension, SiO 2 The mass ratio of / ethanol is 1 / 19.7, and then the suspension is dispersed into a mixed solution of 62.5mL distilled water, 0.75g cetyltrimethylammonium chloride and 6mL ammonia water, so that SiO 2 The mass ratio of / distilled water / hexadecyltrimethylammonium chloride / ammonia water is 2 / 1250 / 15 / 109.2, under stirring, add 0.25mL L 1,4-bis(triethoxysilane) dropwise to the solution base) benzene, reacted for 20 hours, centrifuged, and washed with ethanol and water three times respectively to obtain phenyl hybridized mesoporous SiO 2 layer coated with SiO 2 Nano...

Embodiment 2

[0042] 1) use Core SiO prepared by ber method 2 nanoparticles;

[0043] 2) Using double silicon-based organoalkoxysilane as silicon source and cationic surfactant as pore-forming agent, in the SiO 2 Nanoparticles coated with a layer of SiO hybridized with organic functional groups 2 Layer, the specific process is:

[0044] The 100mg core SiO 2 Nanoparticles dispersed into 2.5mL ethanol to form a suspension, SiO 2 The mass ratio of / ethanol is=1 / 19.7, and then the suspension is dispersed into a mixed solution of 62.5mL distilled water, 0.75g cetyltrimethylammonium chloride and 6mL ammonia water, so that SiO 2 The mass ratio of / distilled water / hexadecyltrimethylammonium chloride / ammonia water is 2 / 1250 / 15 / 109.2, under stirring, add 0.25mL bis(triethoxysilane)ethylene dropwise to the solution, and react for 20h , centrifuged, and washed three times with ethanol and water respectively to obtain vinyl hybrid mesoporous SiO 2 layer coated with SiO 2 Nanoparticle core-shell...

Embodiment 3

[0048] 1) use Core SiO prepared by ber method 2 nanoparticles;

[0049] 2) Using double silicon-based organoalkoxysilane as silicon source and cationic surfactant as pore-forming agent, in the SiO 2 Nanoparticles coated with a layer of SiO hybridized with organic functional groups 2 Layer, the specific process is:

[0050] The 100mg core SiO 2 Nanoparticles dispersed into 2.5mL ethanol to form a suspension, SiO 2 The mass ratio of / ethanol is=1 / 19.7, and then the suspension is dispersed into a mixed solution of 62.5mL distilled water, 0.75g cetyltrimethylammonium chloride and 6mL ammonia water, so that SiO 2 The mass ratio of / distilled water / hexadecyltrimethylammonium chloride / ammonia water is 2 / 1250 / 15 / 109.2. Under stirring, add 0.25mL 1,2-bis(triethoxysilyl ) ethane, reacted for 20h, centrifuged, and then washed 3 times with ethanol and water, respectively, to obtain ethyl-based hybrid mesoporous SiO 2 layer coated with SiO 2 Nanoparticle core-shell material SiO 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com