A method for preparing chitosan antibacterial nanospheres by jet self-excited pulse cavitation enhancement

A technology of nano-microspheres and chitosan, which is applied in botany equipment and methods, fungicides, chemicals for biological control, etc., and can solve the problems of difficult control of microsphere shape, particle size and dispersion, drug loading rate, etc. The problems of low mechanical strength and low mechanical strength of microspheres can achieve the effect of round shape, easy regulation and good dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

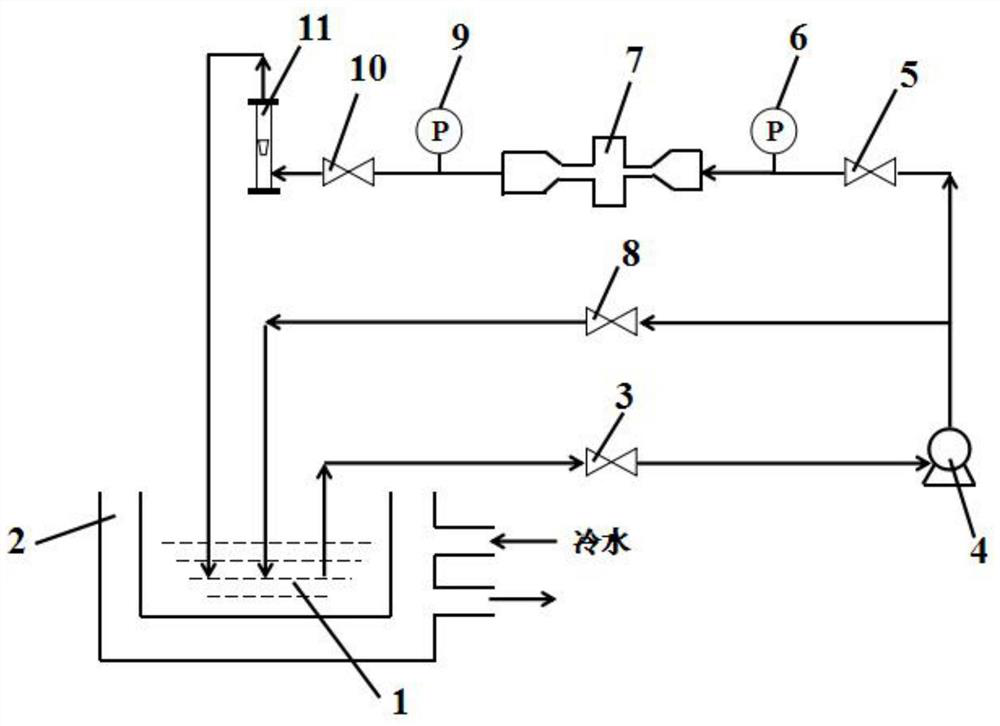

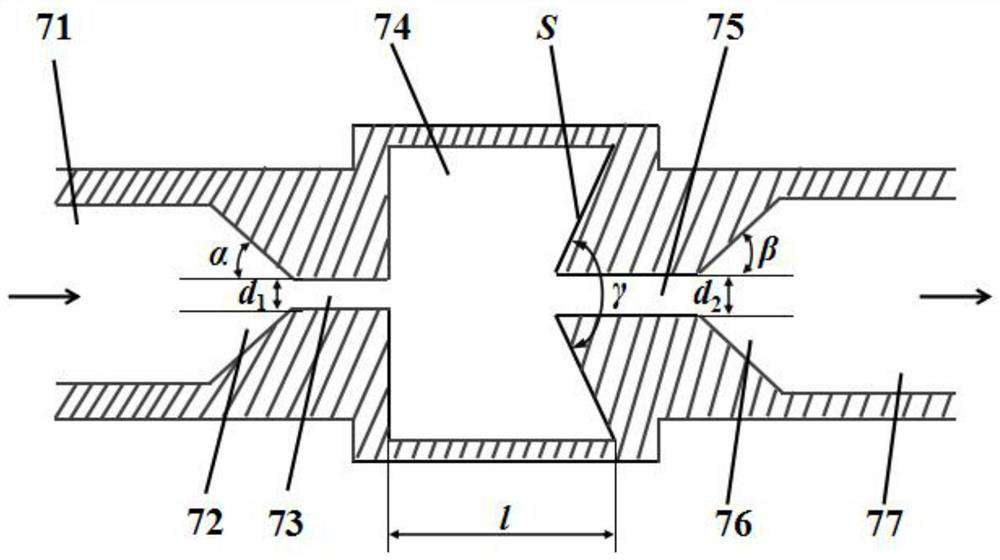

Method used

Image

Examples

Embodiment 1

[0025] A method for preparing chitosan antibacterial nano-microspheres by jet self-excited pulse cavitation strengthening, comprising the following steps:

[0026] (1) Preparation of chitosan solution: Weigh 1.5 g of chitosan sample (molecular weight 50 kDa, degree of deacetylation 85%) and pour it into 1.0 L of formic acid solution (pH 2.16) with mass concentration of 1%. Stir until most of the solids are dissolved, let stand for 2.0 h to fully dissolve the chitosan, remove undissolved chitosan colloid and other impurities with a double-layer filter cloth, and prepare a chitosan solution with a mass concentration of 1.5g / L ;

[0027] (2) Preparation of anionic crosslinking agent solution: Weigh 1.5 g of sodium tripolyphosphate and dissolve it in 1.0 L of deionized water to prepare a sodium tripolyphosphate solution with a mass concentration of 1.5 g / L;

[0028] (3) Preparation of antibacterial agent solution: Weigh 0.58 g of methylisothiazolinone with a mass fraction of 10% ...

Embodiment 2

[0036] A method for preparing chitosan antibacterial nano-microspheres by jet self-excited pulse cavitation strengthening, comprising the following steps:

[0037] (1) Preparation of chitosan solution: Weigh 5.0 g of chitosan sample (molecular weight 90 kDa, degree of deacetylation 95%) and pour it into 1.0 L of citric acid solution with a mass concentration of 1% (pH 2.21) , stir until most of the solids are dissolved, let stand for 2.0 h, let the chitosan fully dissolve, remove the undissolved chitosan colloid and other impurities with a double-layer filter cloth, and prepare chitosan with a mass concentration of 5.0g / L solution;

[0038] (2) Preparation of anionic crosslinking agent solution: Weigh 3.5 g of sodium lauryl sulfate and dissolve it in 1.0 L of deionized water to prepare a sodium lauryl sulfate solution with a mass concentration of 3.5 g / L;

[0039] (3) Preparation of antibacterial agent solution: Weigh 1.15 g of methylisothiazolinone with a mass fraction of 10...

Embodiment 3

[0047] A method for preparing chitosan antibacterial nano-microspheres by jet self-excited pulse cavitation strengthening, comprising the following steps:

[0048] (1) Preparation of chitosan solution: Weigh 8.0 g of chitosan sample (molecular weight 80 kDa, degree of deacetylation 90%) and pour it into 1.0 L of acetic acid-sodium acetate buffer solution with a pH value of 3.6, and stir until large Part of the solid is dissolved, let stand for 2.0 h, let the chitosan fully dissolve, remove the undissolved chitosan colloid and other impurities with a double-layer filter cloth, and make a chitosan solution with a mass concentration of 8.0 g / L;

[0049] (2) Preparation of anionic crosslinking agent solution: Weigh 3.0 g of polyglutamic acid and dissolve it in 1.0 L of deionized water to prepare a polyglutamic acid solution with a mass concentration of 3.0 g / L;

[0050] (3) Preparation of antibacterial agent solution: Weigh 0.34 g of methylisothiazolinone with a mass fraction of 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com