Supported heteropolyacid catalyst, preparation method and application thereof

A heteropolyacid and catalyst technology, applied in the field of catalytic chemistry, can solve the problems that the conversion and utilization of bioglycerol have not been well resolved, increase the risk, and require harsh reaction equipment, and achieve separation and reuse. High, meet the effect of industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The embodiment of the present invention proposes a preparation method of a supported heteropolyacid catalyst, comprising the following steps:

[0021] Step A: immerse the carrier material in the heteropolyacid aqueous solution, stir and mix evenly to obtain a slurry.

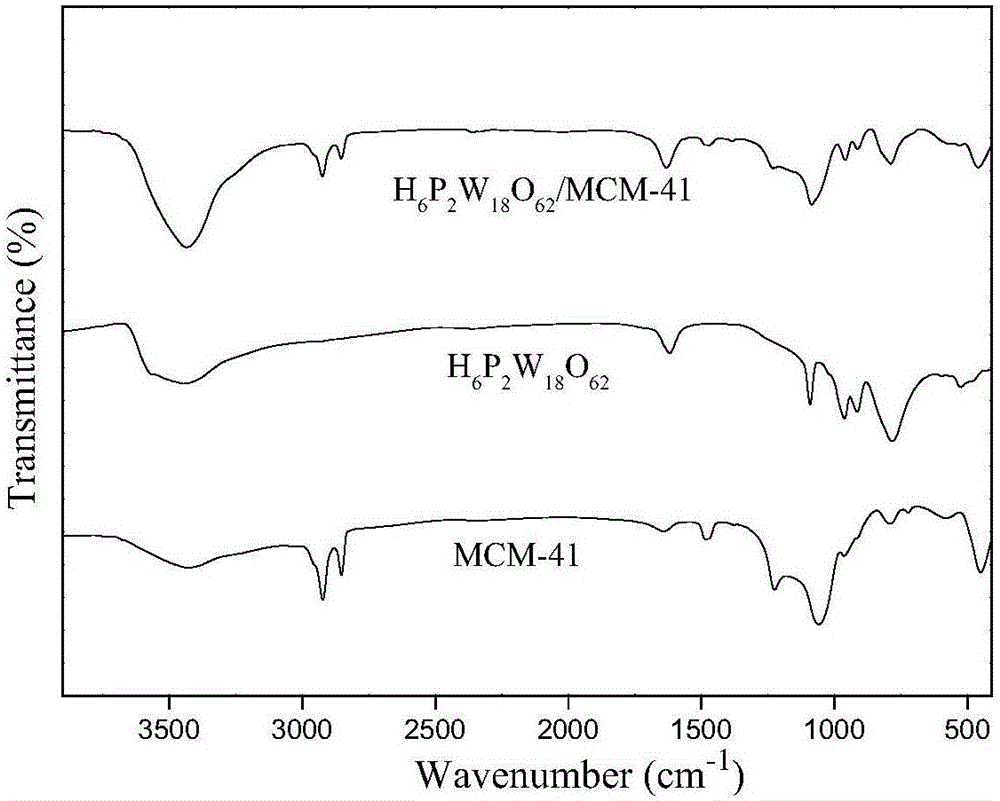

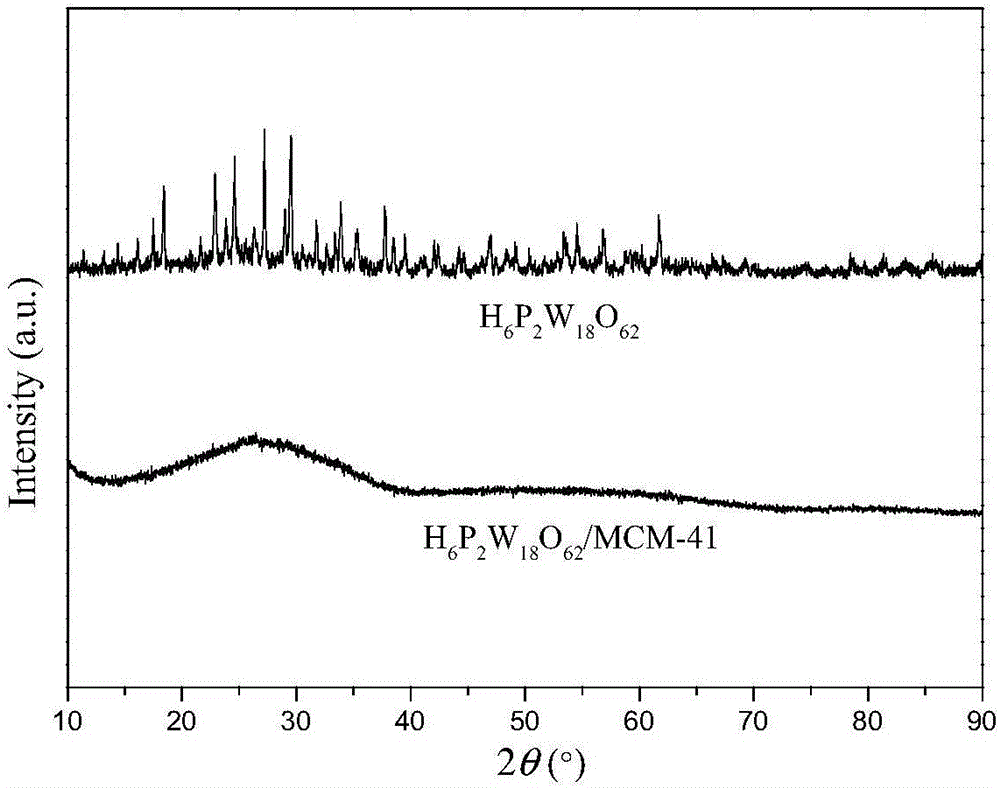

[0022] Specifically, the carrier material is at least one of MCM-41, MCM-48, MCM-50 and FSM-16. MCM-41, MCM-48, MCM-50 and FSM-16 are all pure silica molecular sieves, which can be purchased directly from the market. Among them, MCM-41 pure silicon molecular sieve can also be prepared by the following method: after dissolving the template agent in deionized water, add ammonia solution and mix evenly to obtain solution A; slowly add silicon source dropwise to solution A under constant stirring, After stirring at low temperature for 2-5 hours, the solution B was obtained; the solution B was crystallized at 80-110°C for 40-50 hours, filtered after cooling, and the solid part was collected, washed, dried and...

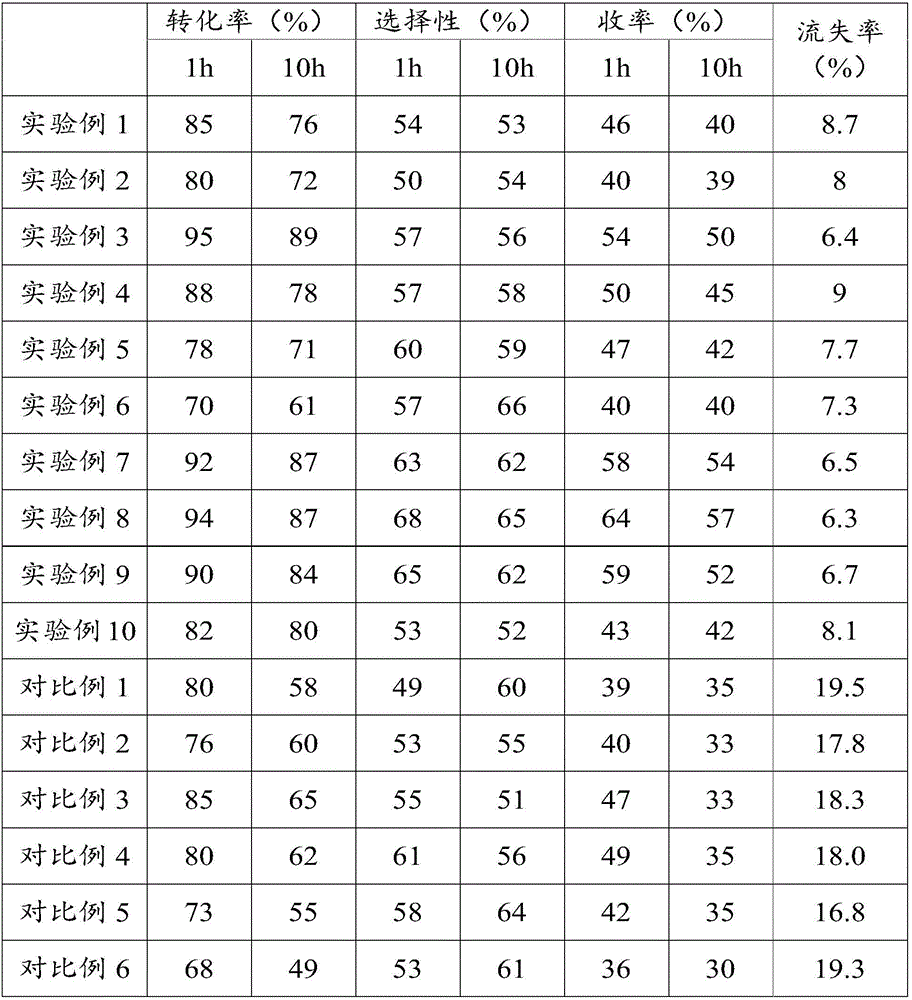

Embodiment 1

[0035] This embodiment provides a supercritical N 2 The phosphotungstic acid / MCM-41 catalyst prepared in the environment, its preparation steps are as follows:

[0036] Dissolve 0.11g of phosphotungstic acid in 20ml of deionized water in the reactor, stir and mix evenly to obtain an aqueous solution of phosphotungstic acid, immerse 1.0g of MCM-41 carrier in the above aqueous solution of phosphotungstic acid, stir and mix evenly to obtain a slurry ; Use temperature program to raise the temperature in the reactor to 60°C, and then use a high-pressure syringe pump to inject N 2 Fill the reaction kettle with gas to make the pressure in the kettle reach 5MPa to reach the supercritical condition, and then maintain the supercritical condition for 2 hours. After the supercritical treatment is completed, lower the temperature, release the pressure, and unload the kettle to obtain the crude catalyst; move the crude catalyst to the centrifuge The tube was centrifuged at 3000r / min for 10...

Embodiment 2

[0039] This embodiment provides a supercritical N 2 The phosphotungstic acid / MCM-41 catalyst prepared in the environment, its preparation steps are as follows:

[0040] Dissolve 0.25g of phosphotungstic acid in 20ml of deionized water in the reaction kettle, stir and mix evenly to obtain an aqueous solution of phosphotungstic acid, immerse 1.0g of MCM-41 carrier in the above aqueous solution of phosphotungstic acid, stir and mix evenly to obtain a slurry ; The temperature in the reactor was raised to 50°C by temperature programming, and then the N 2 Fill the reaction kettle with gas to make the pressure in the kettle reach 6MPa to reach the supercritical condition, and then maintain the supercritical condition for 4 hours. After the supercritical treatment is completed, lower the temperature, release the pressure, and unload the kettle to obtain the crude catalyst; move the crude catalyst to the centrifuge The tube was centrifuged at 5000r / min for 15min, and the solid part of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com