Coating film forming system and coating film forming method

A coating film and coating technology, applied in the direction of coating, liquid coating device on the surface, progressive drying machine, etc., can solve the problems of measuring the temperature of the substrate, not giving enlightenment, inappropriate drying treatment, etc. Achieve long drying time and prolong the effect of transporting distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Embodiments of the present invention will be described below with reference to the drawings. In addition, the constituent elements described in this embodiment are merely illustrative, and are not intended to limit the scope of protection of the present invention thereto. In addition, in the drawings, the size or number of each part may be exaggerated or simplified as necessary for easy understanding.

[0065]

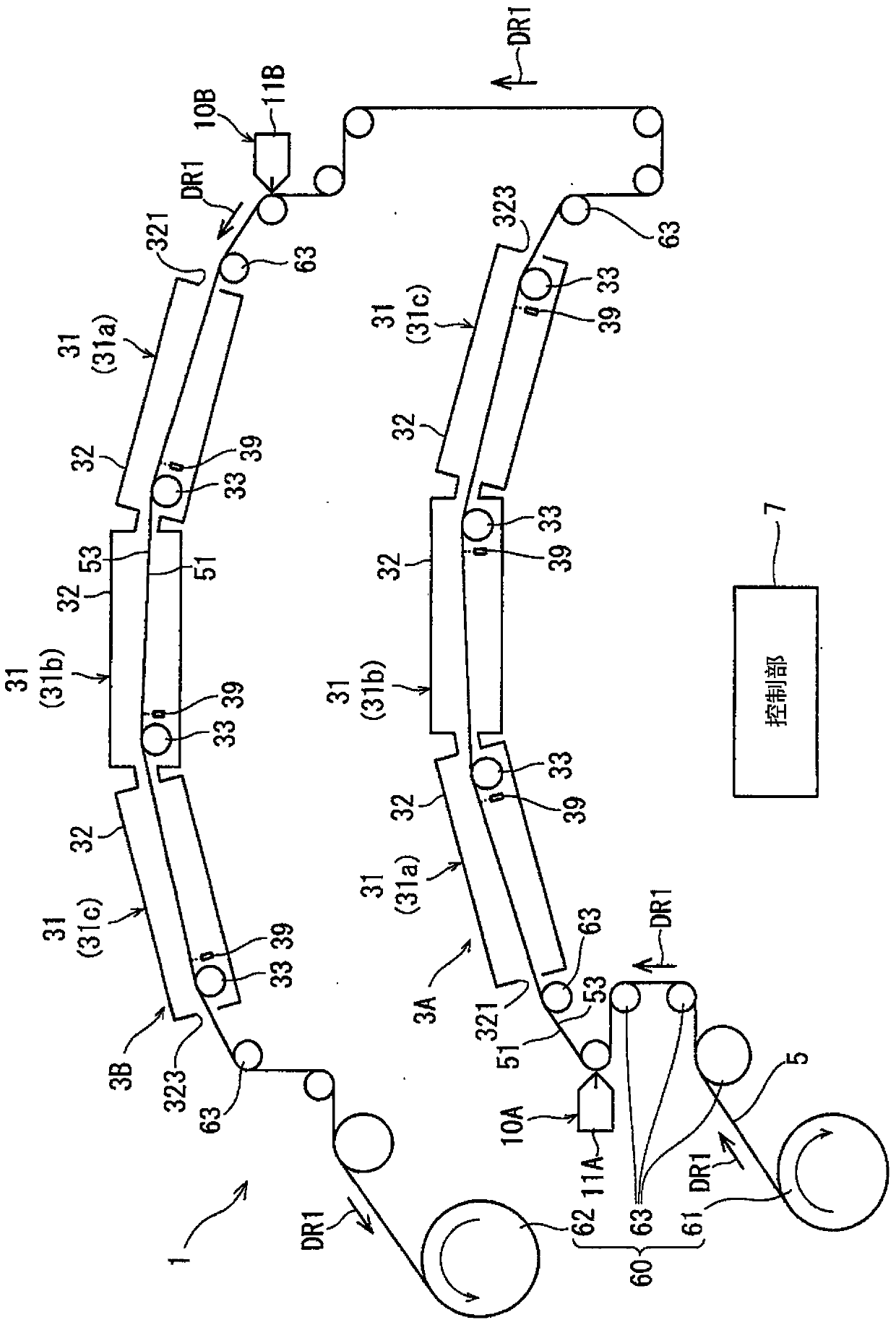

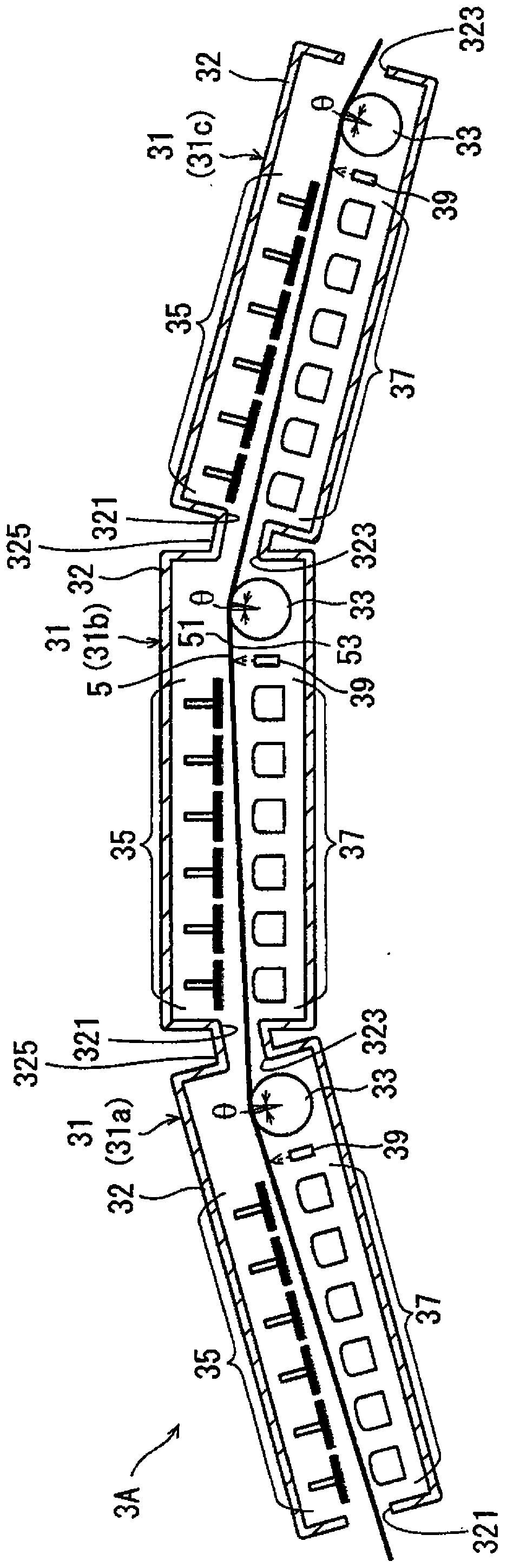

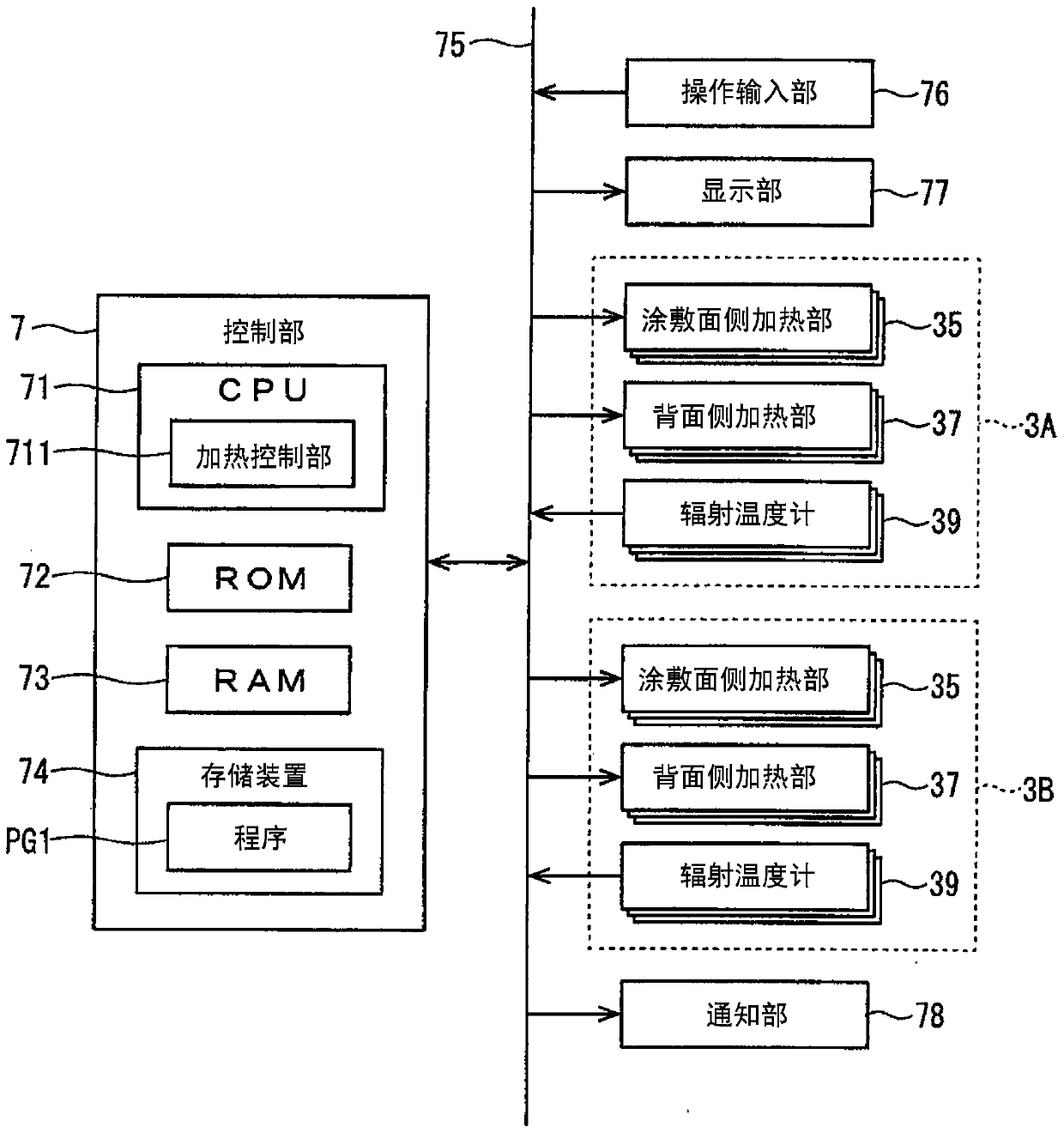

[0066] figure 1 It is a schematic configuration diagram showing the coating film forming system 1 including drying devices 3A and 3B according to the embodiment.

[0067] This coated film forming system 1 continuously conveys a substrate 5 which is, for example, a long metal foil in a roll-to-roll system, and coats both surfaces of the substrate 5 containing A slurry coating solution of active substances. Then, the drying treatment of this coating liquid is performed, and the electrode of a lithium ion secondary battery is manufactured.

[0068] The coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com