High-strength PC modified carrier tape material

A modified material, high-strength technology, applied in layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of easy formation of holes, poor temperature resistance, low material strength, etc., and achieve simple manufacturing. , good temperature resistance, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

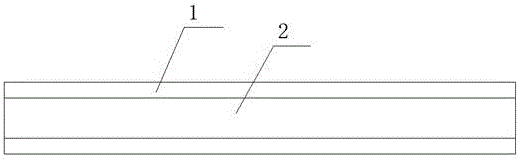

Image

Examples

Embodiment

[0035] Step 1) Stir 20KG pure PC material, 1KG GABS material, 50g phase solvent, 25g antioxidant 168, / 025g antioxidant 1076 in a sealed high-speed mixer at room temperature for 3 minutes (slowly heat during the period), and wait for the mixing tank After the body temperature reaches 50 degrees Celsius, stir again at high speed for 5 minutes.

[0036] Step 2) Use a twin-screw extruder to modify the mixture obtained in step 1) at a temperature of 220-250 degrees Celsius, extrude, pelletize, and shape, wherein the material has almost no Burrs and lint are significantly reduced after material slitting.

[0037] Step 3) The modified material obtained in step 2) is dried in a crystallization dryer at a temperature of 100 degrees Celsius for 3 hours, and then used as the main material (intermediate layer) of the PC carrier material, passed through the extruder (heating 200 -240 degrees Celsius) composite, the surface layer uses PS conductive masterbatch to obtain the carrier tape m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com