A kind of highly elastic nanofiber multi-component composite nonwoven material and its preparation method

A technology of non-woven materials and nanofibers, applied in the field of non-woven materials, can solve problems such as low elasticity and single performance, achieve good hydrophilic performance, improve elastic performance, and improve comfort

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

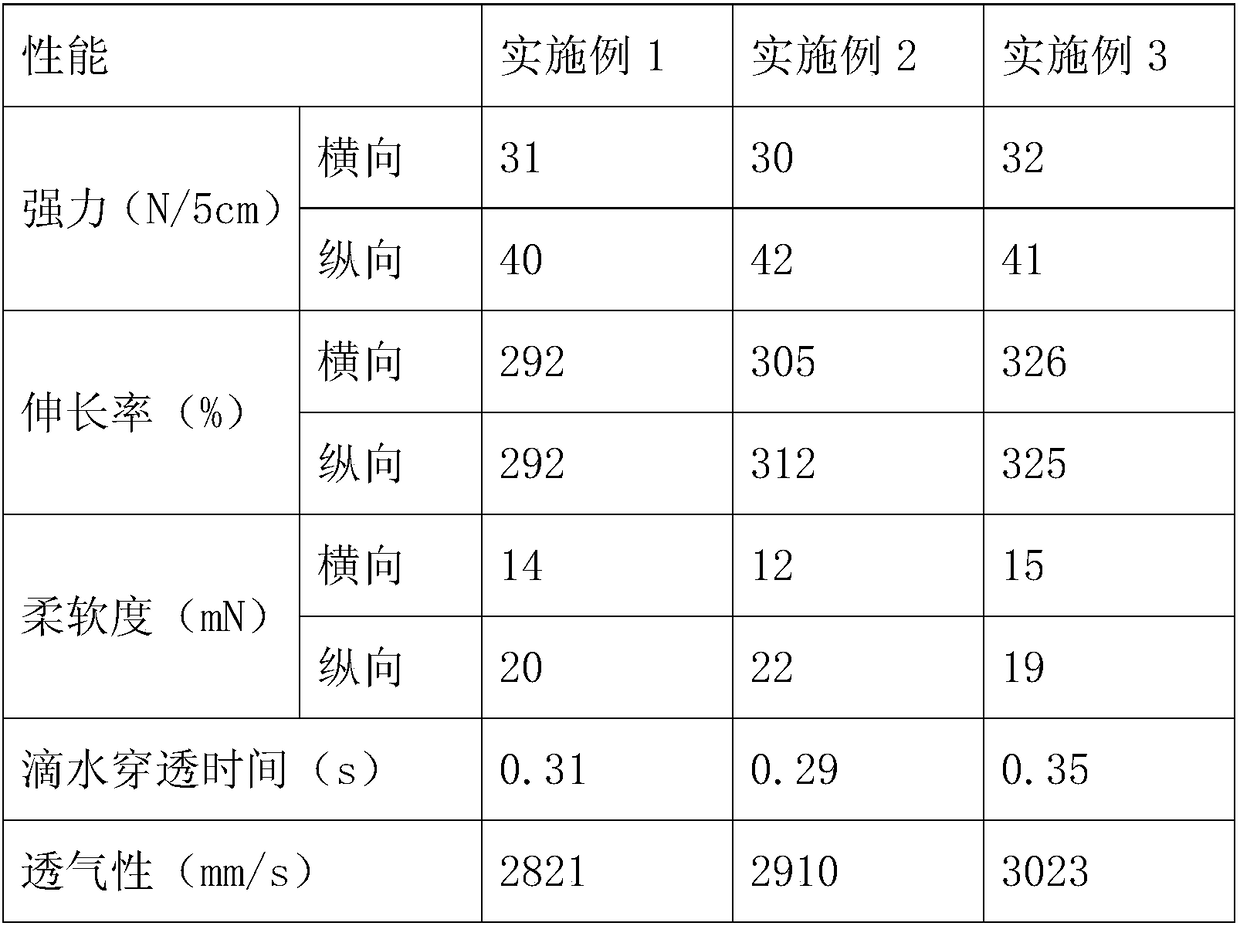

Examples

Embodiment 1

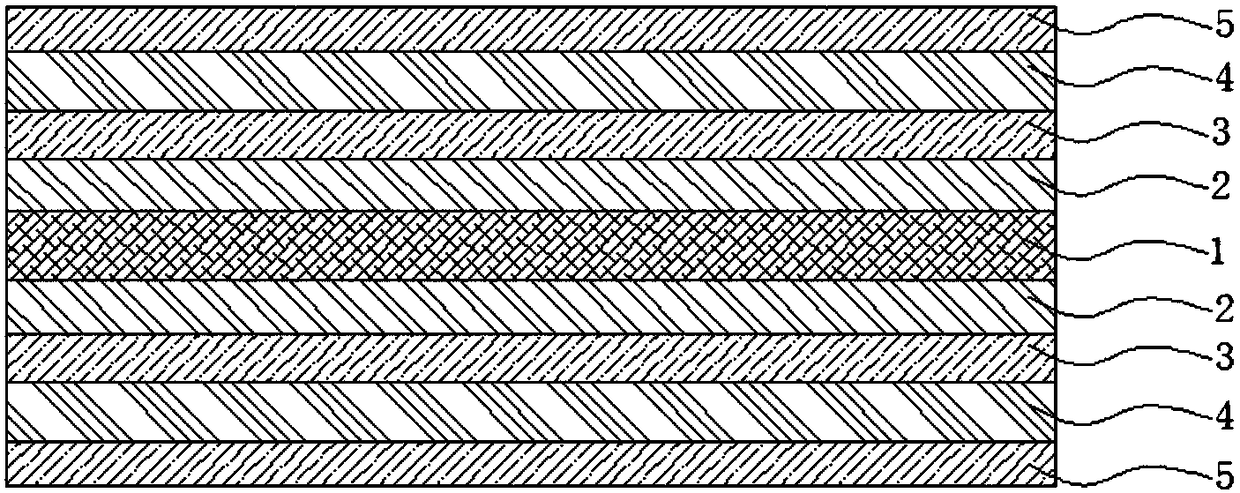

[0029] The high-elastic nanofiber multi-component composite nonwoven material of the present embodiment comprises a matrix layer 1, and both sides of the matrix layer 1 are sequentially provided with an elastic layer 2, a soft layer 3, a hydrophilic layer 4 and an antibacterial layer from the inside to the outside. Layer 5, the elastic layer 2 is prepared by adding elastic masterbatch in polypropylene fiber through spinning;

[0030] Wherein, the matrix layer 1 is a polypropylene fiber layer, the elastic masterbatch is a polyamide thermoplastic elastomer, and the hydrophilic layer 4 is prepared from 91.2wt% of polypropylene, 8wt% of antioxidant and 0.8wt% of hydrophilic agent; The thickness of layer 4 is 60 μ m, and soft layer is that softening agent aqueous solution is coated on polypropylene fiber and makes; The thickness of soft layer 3 is 20 μ m, and the thickness of elastic layer 2 is 42 μ m, and the diameter of polypropylene fiber in elastic layer 2 is 40nm , the thickne...

Embodiment 2

[0035] The high-elastic nanofiber multi-component composite nonwoven material of the present embodiment comprises a matrix layer 1, and both sides of the matrix layer 1 are sequentially provided with an elastic layer 2, a soft layer 3, a hydrophilic layer 4 and an antibacterial layer from the inside to the outside. Layer 5, the elastic layer 2 is prepared by adding elastic masterbatch to polypropylene fiber and spinning.

[0036] Wherein, the matrix layer 1 is a polypropylene fiber layer, the elastic masterbatch is a polyamide thermoplastic elastomer, and the hydrophilic layer 4 is prepared from 91.6wt% of polypropylene, 8wt% of antioxidant and 0.4wt% of hydrophilic agent; The thickness of layer 4 is 66 μ m, and soft layer is that softening agent aqueous solution is coated on polypropylene fiber and makes; The thickness of soft layer 3 is 22 μ m, and the thickness of elastic layer 2 is 46 μ m, and the diameter of polypropylene fiber in elastic layer 2 is 44nm , the thickness o...

Embodiment 3

[0041] The high-elastic nanofiber multi-component composite nonwoven material of the present embodiment comprises a matrix layer 1, and both sides of the matrix layer 1 are sequentially provided with an elastic layer 2, a soft layer 3, a hydrophilic layer 4 and an antibacterial layer from the inside to the outside. Layer 5, the elastic layer 2 is prepared by adding elastic masterbatch in polypropylene fiber through spinning;

[0042] Wherein, the matrix layer 1 is a polypropylene fiber layer, the elastic masterbatch is a polyamide thermoplastic elastomer, and the hydrophilic layer 4 is prepared from 90wt% polypropylene, 9.5wt% antioxidant and 0.5wt% hydrophilic agent; The thickness of layer 4 is 70 μ m, and soft layer is that softening agent aqueous solution is coated on polypropylene fiber and makes; The thickness of soft layer 3 is 25 μ m, and the thickness of elastic layer 2 is 46 μ m, and the diameter of polypropylene fiber in elastic layer 2 is 52nm , the thickness of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com