Silk-like cotton organic silicon fiber finishing agent

A technology of fiber finishing and silicone, which is applied in fiber treatment, plant fiber, wear-resistant fiber, etc., can solve problems such as the inability to change the elasticity of imitation silk floss, the bad experience of users, and the inability to change the pilling and fluffing of imitation silk floss. Achieve the effects of improving cohesion, improving elastic properties and improving toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

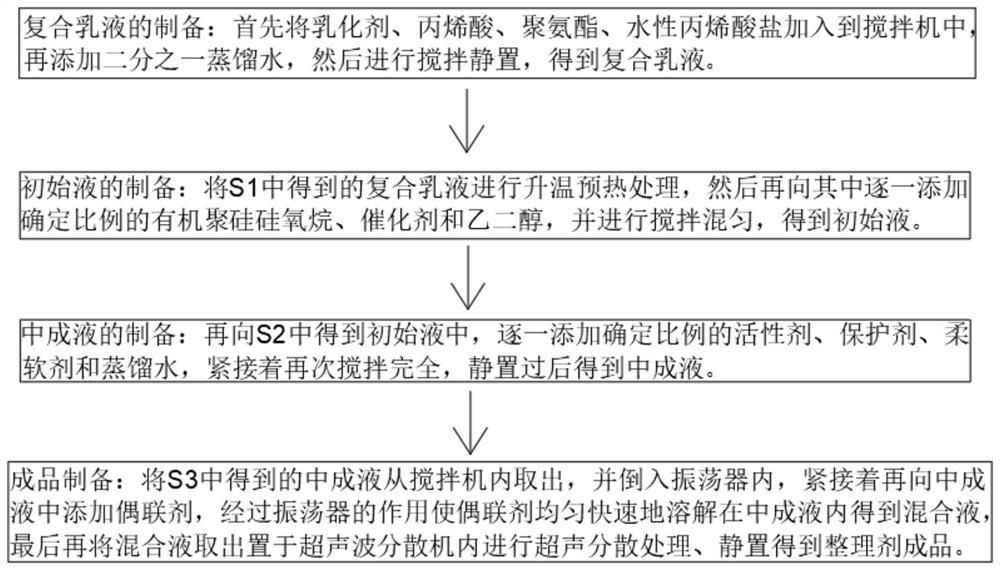

[0028] Example 1, please refer to figure 1 , silk-like silicone fiber finishing agent, silk-like silicone fiber finishing agent is composed of organopolysiloxane, ethylene glycol, catalyst, composite emulsion, active agent, protective agent, softener, coupling agent and distilled water, and The specific gravity of each component is as follows: 10 parts of organopolysiloxane, 2 parts of ethylene glycol, 1 part of catalyst, 10 parts of composite emulsion, 2 parts of active agent, 1 part of protective agent, 1 part of softener, 3 parts of coupling agent , 70 parts of distilled water.

[0029] Include the following steps:

[0030] S1: Preparation of composite emulsion: First, add emulsifier, acrylic acid, polyurethane, and water-based acrylate to the mixer, then add 1 / 2 of distilled water, then stir and let stand. The speed of the mixer is 550r / min, which can ensure complete mixing , and the surface speed is too fast to cause the interior of the composite emulsion to be destroye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com