High-wear-resistance plastic track colloidal particles and preparation method thereof

A plastic runway, high wear-resistant technology, applied in the field of plastic runway, can solve the problems of brittleness and hardening of rubber particles, decrease in elastic effect, etc., and achieve the effect of inhibiting the release of smoke, prolonging service life, and ensuring elasticity and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026]The invention provides a high wear-resistant plastic runway colloid, comprising: 37.60kg of thermoplastic polyurethane, 14.40kg of silicone resin, 7.40kg of foaming agent, 1.30kg of colorant, 1.80kg of disulfide bond crosslinking agent, 0.20kg of antioxidant, 0.20kg of anti-aging agent, 0.20kg of initiator, 0.20kg of vulcanizing agent, 36.70kg of composite filler; the composite filler includes: 9.6521kg of nano-silica, 11.5238kg of hexagonal boron nitride, 2.8993kg of graphene oxide, 2.8993kg of nano-titanium dioxide, 2.8993kg of manganese dioxide, 0.2569kg of KH-550 coupling agent, 6.5693kg of bamboo fiber;

[0027] The foaming agent is a compound mixture of AC foaming agent and ADC foaming agent; The antioxidant is a compound mixture of antioxidant 1076 and antioxidant 164; the antioxidant is N, N-diphenyl-p-phenylenediamine or microcrystalline wax;

[0028] A method for preparing high wear-resistant plastic runway colloids, the specific preparation steps are as follo...

Embodiment 2

[0037] The difference from Example 1 is that it includes: 38.60kg of thermoplastic polyurethane, 15.40kg of silicone resin, 8.40kg of foaming agent, 1.70kg of colorant, 2.20kg of disulfide bond crosslinking agent, 0.40kg of anti Oxidant, 0.40kg of anti-aging agent, 0.40kg of initiator, 0.40kg of vulcanizing agent, 32.10kg of composite filler; the composite filler includes: 8.6349kg of nano-silica, 10.2078kg of hexagonal nitride Boron, 2.7927kg of graphene oxide, 2.7927kg of nano-titanium dioxide, 2.7927kg of manganese dioxide, 0.2889kg of KH-550 coupling agent, 4.5903kg of bamboo fiber.

Embodiment 3

[0039] All different from Examples 1-2, including: 38.10kg of thermoplastic polyurethane, 14.90kg of silicone resin, 7.90kg of foaming agent, 1.50kg of coloring agent, 2.00kg of disulfide bond crosslinking agent, 0.30 kg of antioxidants, 0.30kg of anti-aging agents, 0.30kg of initiators, 0.30kg of vulcanizing agents, and 34.40kg of composite fillers; the composite fillers include: 9.1504kg of nano-silica, 10.8704kg of Hexagonal boron nitride, 2.8552kg of graphene oxide, 2.8552kg of nano-titanium dioxide, 2.8552kg of manganese dioxide, 0.2752kg of KH-550 coupling agent, and 5.5384kg of bamboo fiber.

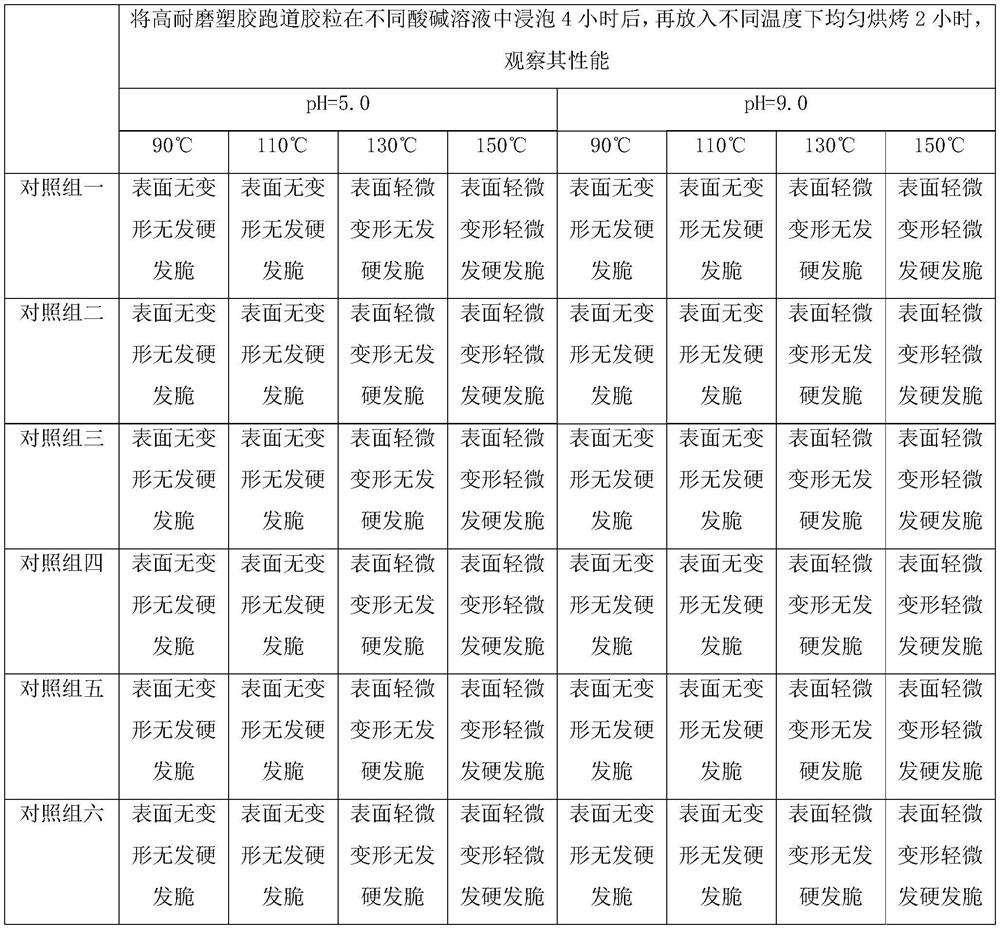

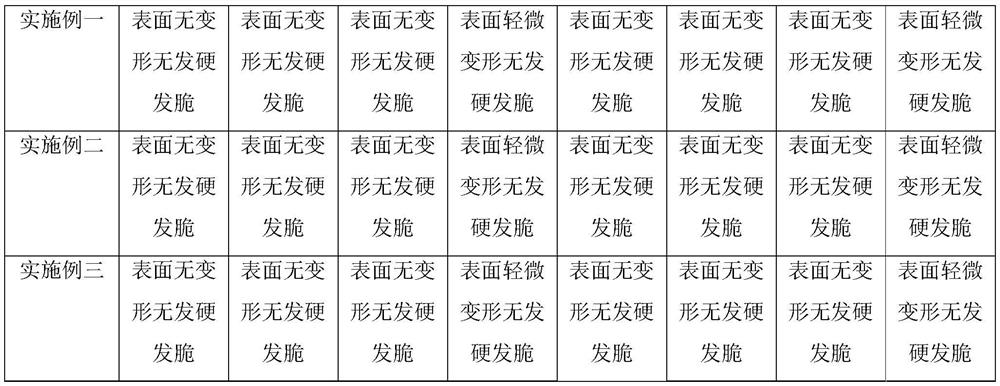

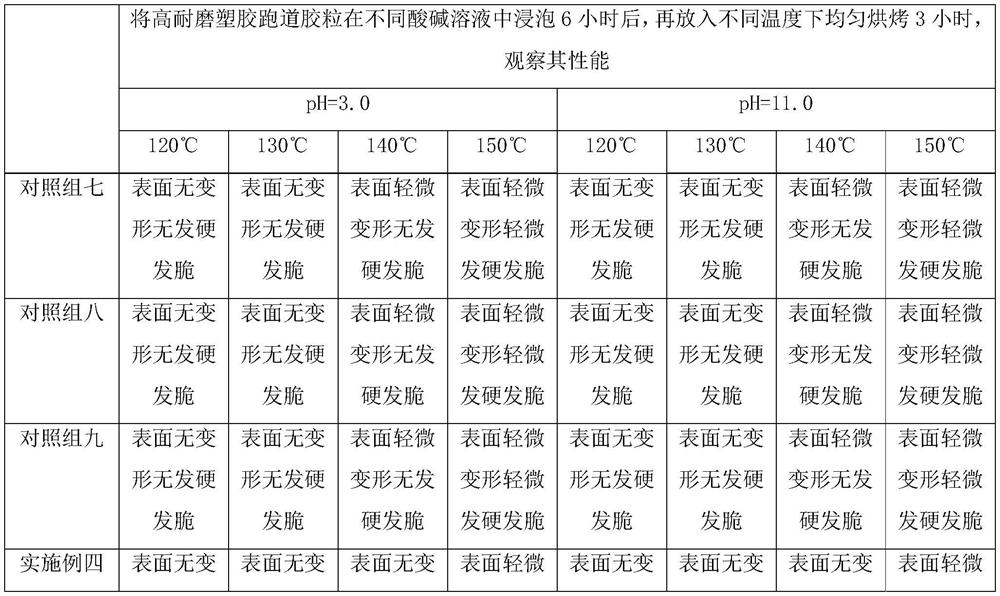

[0040] Take respectively the high wear-resistant plastic runway rubber particles prepared in the above-mentioned embodiments 1-3 and the high wear-resistant plastic runway rubber particles of the control group one, the high wear-resistant plastic runway rubber particles of the matched group two, and the high wear-resistant plastic runway rubber particles of the matched group three....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com