Sewage treatment agent and preparation method thereof

A sewage treatment agent, rectorite technology, applied in water/sewage treatment, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve secondary pollution and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

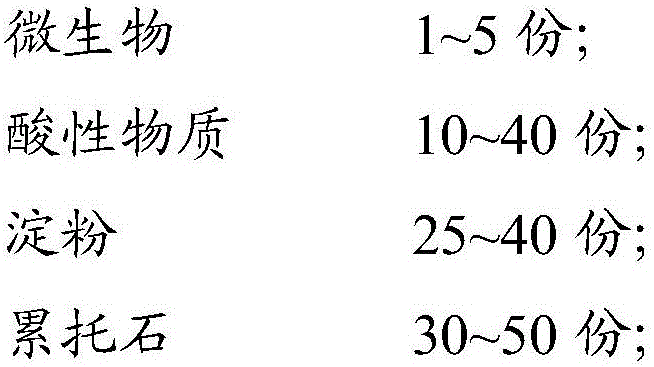

Method used

Image

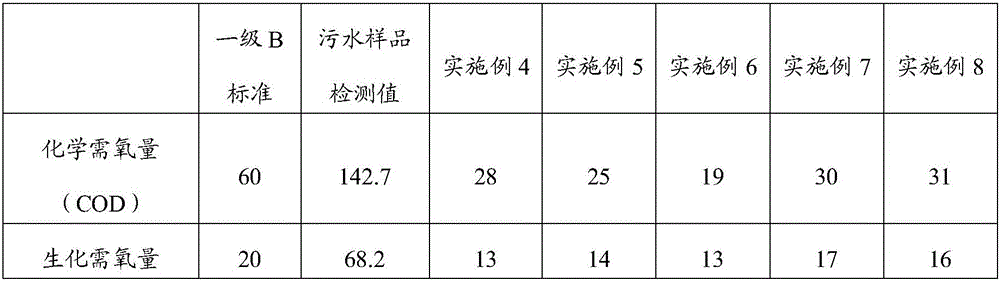

Examples

preparation example Construction

[0037] In an embodiment of the present invention, the preparation method of the polyacrylic acid-modified rectorite comprises the following steps:

[0038] 1) Add 800-1500 parts by weight of water to 80-120 parts by weight of rectorite, and stir at 30-50° C. for 15-24 hours to obtain a mixed solution;

[0039] 2) Add 1 to 3 parts by weight of dopamine hydrochloride to the mixed solution obtained in step 1), and stir at 40 to 60° C. for 24 to 48 hours to obtain dopamine hydrochloride modified rectorite;

[0040] 3) adding 10-20 parts by weight of polyacrylic acid to the dopamine hydrochloride-modified rectorite obtained in step 2), and stirring at 60-80° C. for 24-48 hours to obtain a semi-finished product of polyacrylic acid-modified rectorite;

[0041] 4) cooling, filtering, and drying the semi-finished polyacrylic acid-modified rectorite obtained in step 3), that is, the obtained polyacrylic acid-modified rectorite.

[0042] In an embodiment of the present invention, the re...

Embodiment 1

[0067] Add 800 g of water to 100 g of rectorite, stir at 30° C. for 15 h to obtain a mixed solution; add 1 g of dopamine hydrochloride to the mixed solution, and stir at 40° C. for 36 h to obtain dopamine hydrochloride modified rectorite; Add 20g of polyacrylic acid to the rectorite modified by dopamine hydrochloride, stir at 70°C for 36h to obtain a semi-finished product of polyacrylic acid modified rectorite; cool, filter and dry the semi-finished product of polyacrylic acid modified rectorite, That is, the obtained polyacrylic acid-modified rectorite.

Embodiment 2

[0069] Add 1200g of water to 120g of rectorite, stir at 40°C for 24h to obtain a mixed solution; add 2g of dopamine hydrochloride to the mixed solution, and stir at 50°C for 24h to obtain dopamine hydrochloride modified rectorite; Add 15g of polyacrylic acid to the dopamine hydrochloride modified rectorite, stir at 80°C for 24h to obtain a semi-finished product of polyacrylic acid modified rectorite; cool, filter and dry the semi-finished product of polyacrylic acid modified rectorite, That is, the obtained polyacrylic acid-modified rectorite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com