Carbon tetrachloride sludge treatment agent and preparation method thereof

A technology of sludge treatment and carbon tetrachloride, which is applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., to achieve the effects of cost reduction, simple treatment process and good treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

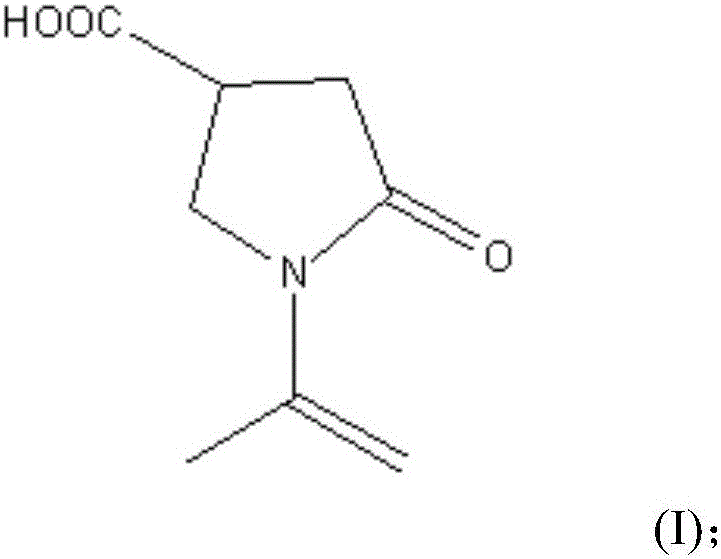

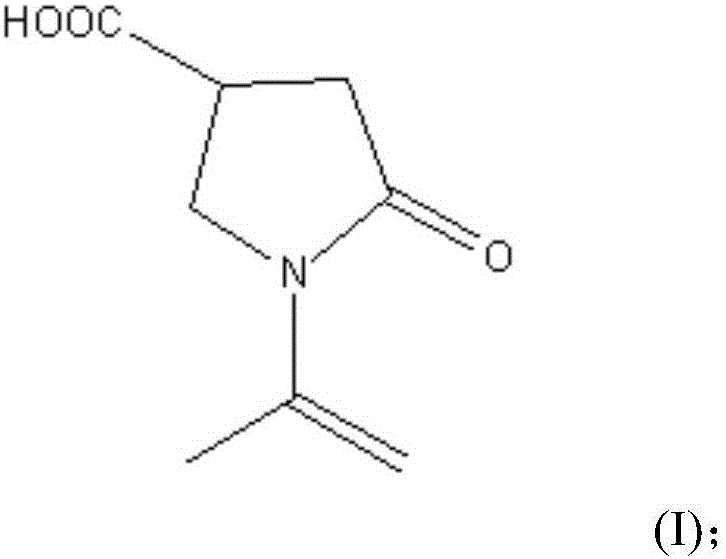

[0030] A carbon tetrachloride sludge treatment agent, the main raw materials in parts by weight are: 20 parts of modified saline-alkali soil, 12 parts of auxiliary agent, 2 parts of triethanolamine, 0.1 part of sodium lauryl sulfate; the modified salt The preparation method of alkaline earth is: drying and crushing saline-alkali earth into 300-mesh fine powder, then soaking the fine powder in dodecyl betaine, soaking for 12 hours, transferring to the reaction kettle, and adding cinnamene, citric acid and spit Temperature, under 0.3MPa pressure, 74 ℃ reacts 1h and then dries to get final product; The auxiliary agent includes the following two auxiliary agent components: one of them is the auxiliary agent component A of the chemical formula (I), and the content is the auxiliary agent component 30% of the total weight,

[0031]

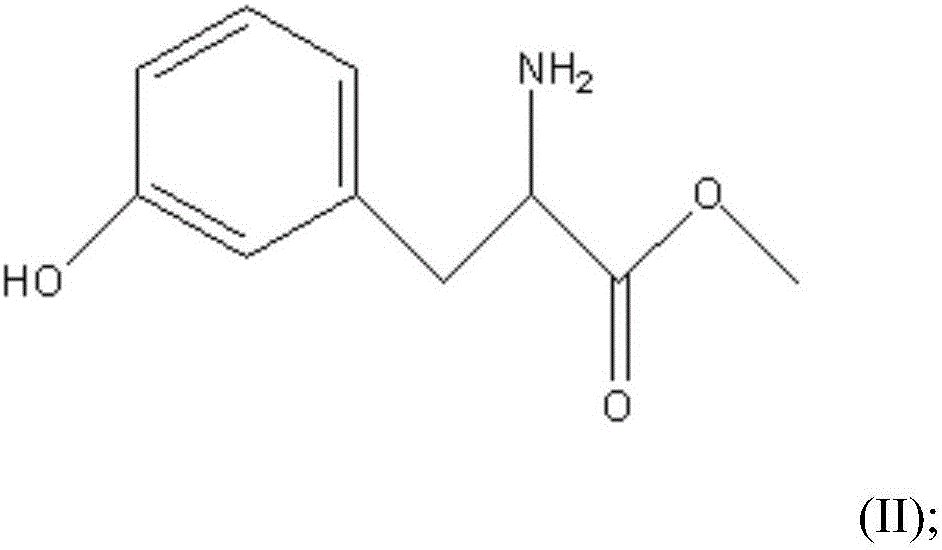

[0032] The second is the auxiliary component B of the chemical formula (II), and the content is 70% of the total weight of the auxiliary component, ...

Embodiment 2

[0039] A carbon tetrachloride sludge treatment agent, the main raw materials in parts by weight are: 23 parts of modified saline-alkali soil, 14 parts of auxiliary agent, 2 parts of triethanolamine, 0.1 part of sodium lauryl sulfate; the modified salt The preparation method of alkaline earth is: drying and crushing saline-alkali earth into 300-mesh fine powder, then soaking the fine powder in dodecyl betaine, soaking for 12 hours, transferring to the reaction kettle, and adding cinnamene, citric acid and spit Temperature, under 0.3MPa pressure, 74 ℃ reacts 1h and then dries to get final product; The auxiliary agent includes the following two auxiliary agent components: one of them is the auxiliary agent component A of the chemical formula (I), and the content is the auxiliary agent component 35% of the total weight,

[0040]

[0041] The second is the auxiliary component B of chemical formula (II), and the content is 65% of the total weight of the auxiliary component,

[0...

Embodiment 3

[0048]A carbon tetrachloride sludge treatment agent, the main raw materials in parts by weight are: 25 parts of modified saline-alkali soil, 15 parts of auxiliary agent, 4 parts of triethanolamine, 0.2 part of sodium lauryl sulfate; the modified salt The preparation method of alkaline earth is: drying and crushing saline-alkali earth into 300-mesh fine powder, then soaking the fine powder in dodecyl betaine, soaking for 12 hours, transferring to the reaction kettle, and adding cinnamene, citric acid and spit Temperature, under 0.3MPa pressure, 76 ℃ reacts 1h and then dries to get final product; Said auxiliary agent comprises following two auxiliary agent components: one of them is auxiliary agent component A of chemical formula (I), and content is auxiliary agent component 40% of the total weight,

[0049]

[0050] The second is the auxiliary component B of chemical formula (II), and the content is 60% of the total weight of the auxiliary component,

[0051]

[0052] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com